Lubricating system

A lubricating system and lubricating pump technology, which is applied in the field of lubricating systems, can solve the problems of a large number of lubricators and high costs, and achieve the effects of improving lubricating efficiency, saving electric energy, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

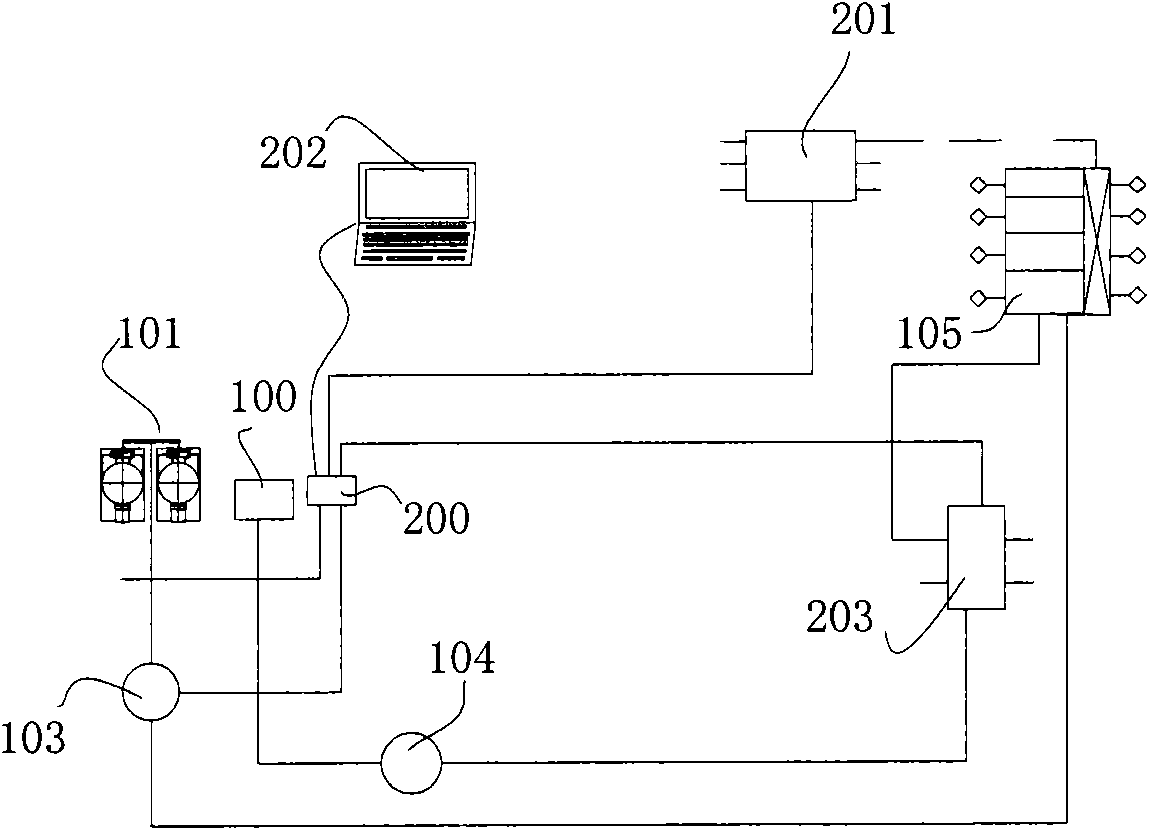

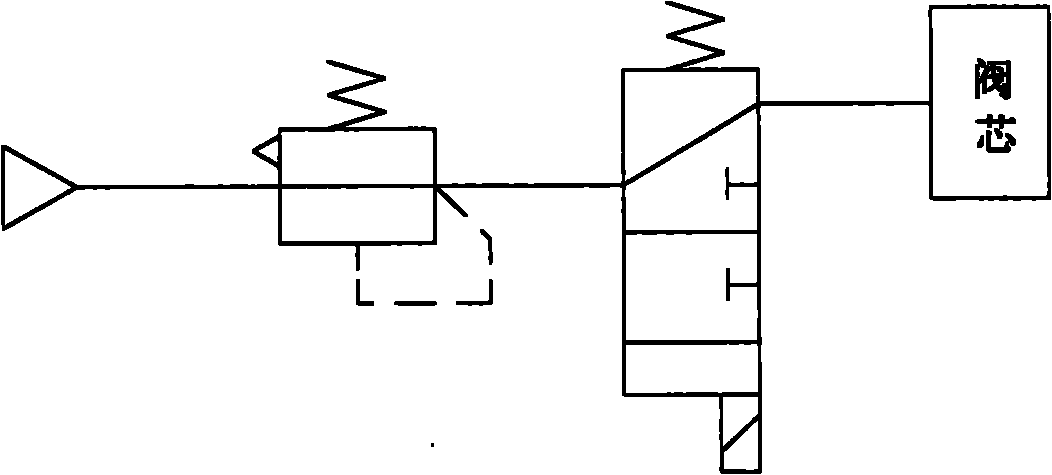

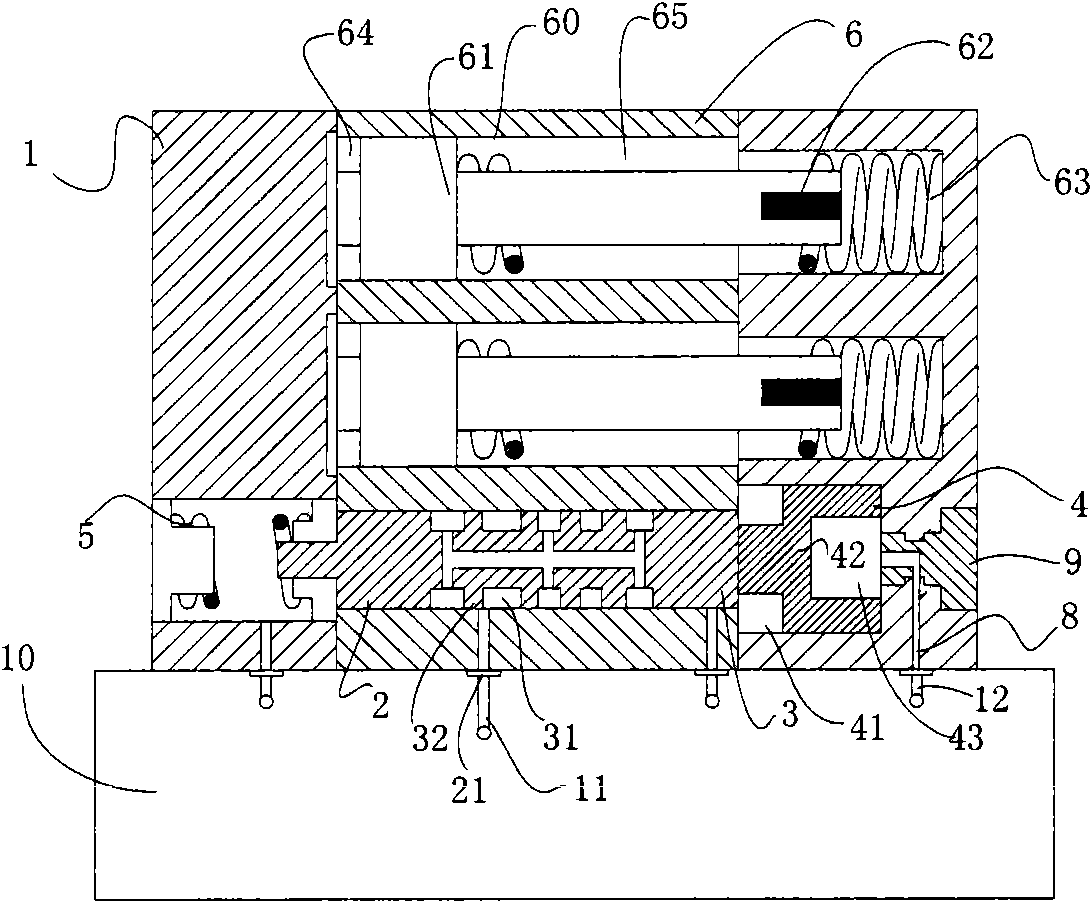

[0031] The structure of the air-controlled intelligent lubrication system described in the present invention is as follows: figure 1 As shown, it includes an oil feeding device and a control device. The oil feeding device includes a lubricating pump 101, an oil delivery pipeline connecting the lubrication pump 101 and a lubrication point, and an oil feeder 105 installed on the oil delivery pipeline. The oil feeder 105 It includes a housing 1, a spool chamber 2 is opened in the housing 1, a spool 3 that can slide axially is arranged in the spool chamber 2, and a spool 3 is installed on one side of the spool 3 to make the The biasing part for the reset of the valve core 3 also includes a compressed gas source 100, and a gas channel is formed on the housing 1 on one side of the valve core 3, and the gas channel communicates with the compressed gas source 100, and the compressed gas source 100 The gas in the gas source 100 is used to drive the valve core 3 . The compressed gas so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com