Impulse type drip irrigation system

A pulse and pulse valve technology, applied in the field of farmland irrigation, can solve the problems such as the inability to adjust the irrigation intensity according to the needs, the high pulse frequency, the blockage of the negative pressure suction outlet holes, etc. easy to accept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

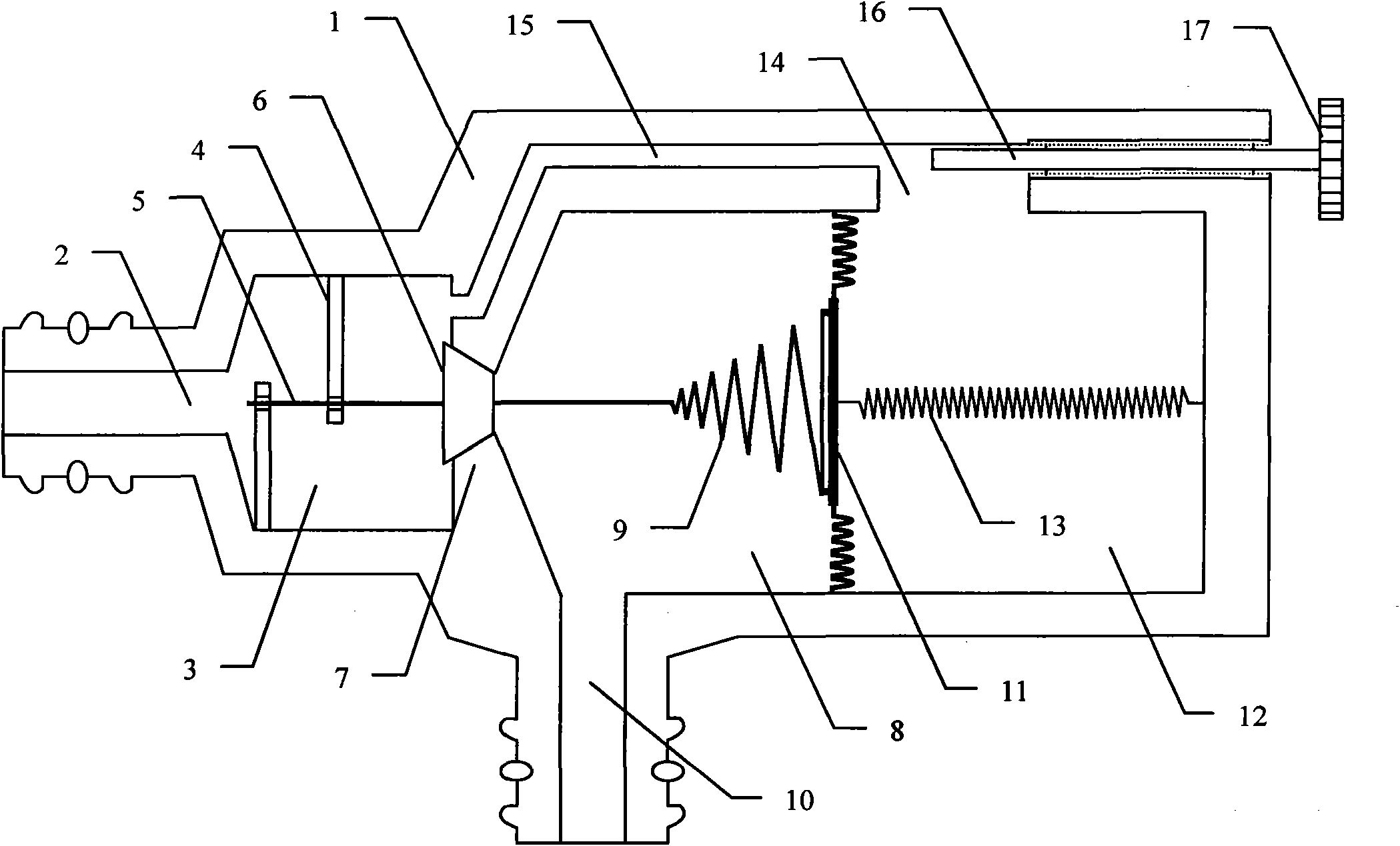

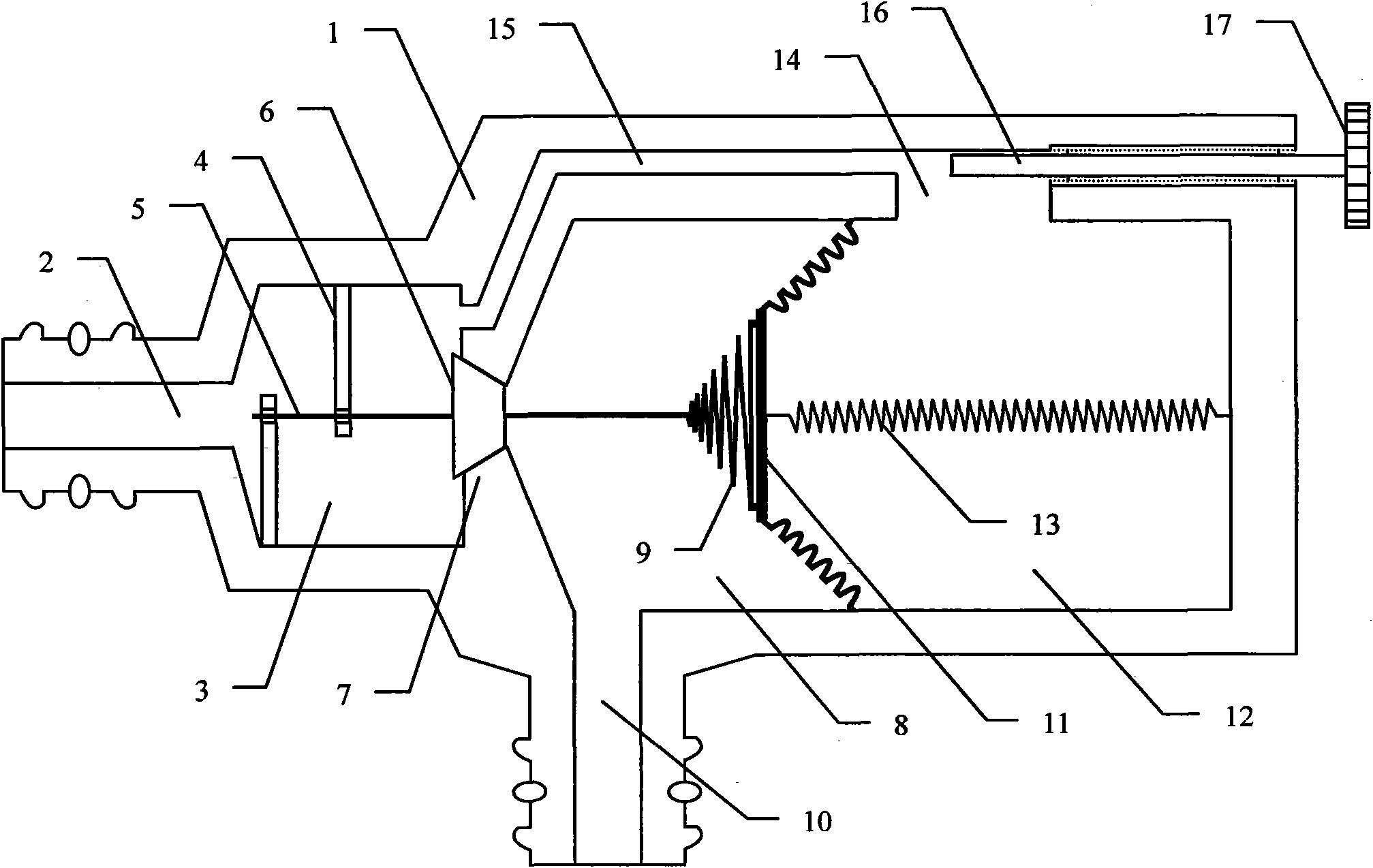

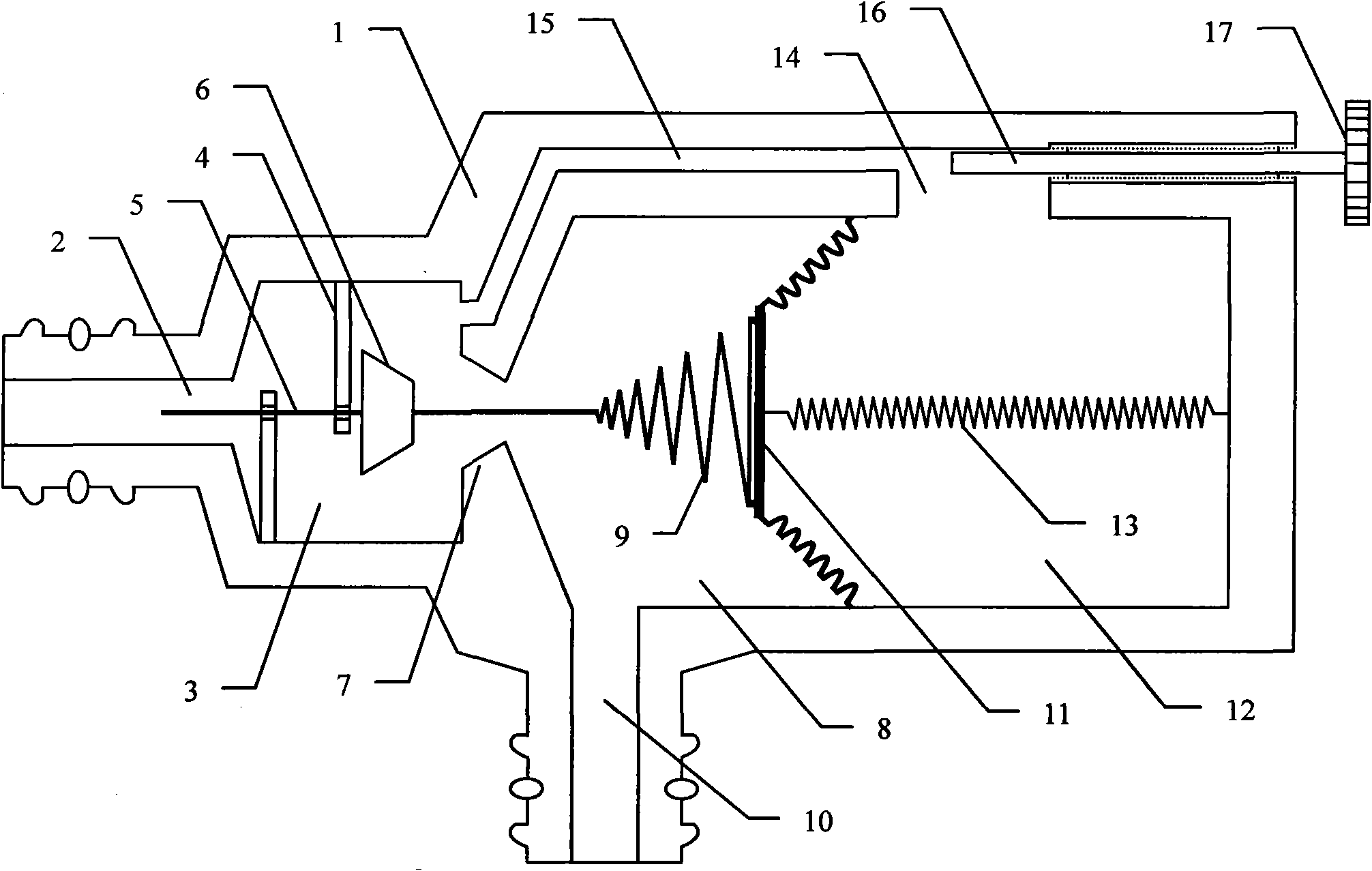

[0024] A pulse drip irrigation system, comprising: a water source, a water pump, a main pipe, a branch pipe, a pulse valve, a capillary pipe, and a drip irrigation dispenser; the water inlet of the water pump is connected to the water source; the water outlet of the water pump is connected to the water inlet of the main pipe; The branch pipe is connected, and the branch pipe is connected with several capillary pipes through several pulse valves. The water inlet of the pulse valve leads to the branch pipe, and the water outlet of the pulse valve leads to the capillary pipe. figure 1 , figure 2 , image 3 As shown, it includes: valve body 1, water inlet 2, water inlet cavity 3, gate body guide rod bracket 4, gate body guide rod 5, gate body 6, gate groove 7, water outlet cavity 8, gate body push-pull spring 9, outlet Nozzle 10, diaphragm 11, control chamber 12, diaphragm tension spring 13, control chamber water inlet and outlet 14, control chamber inlet and outlet pipe 15, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com