A method for automatic cleaning and maintenance of continuous casting secondary cooling nozzle

An automatic cleaning and nozzle technology, which is applied in the field of steelmaking-continuous casting, can solve problems such as secondary cooling nozzle clogging, achieve the effects of improving surface quality and internal quality, good anti-clogging performance, reducing corner cutting rate and peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

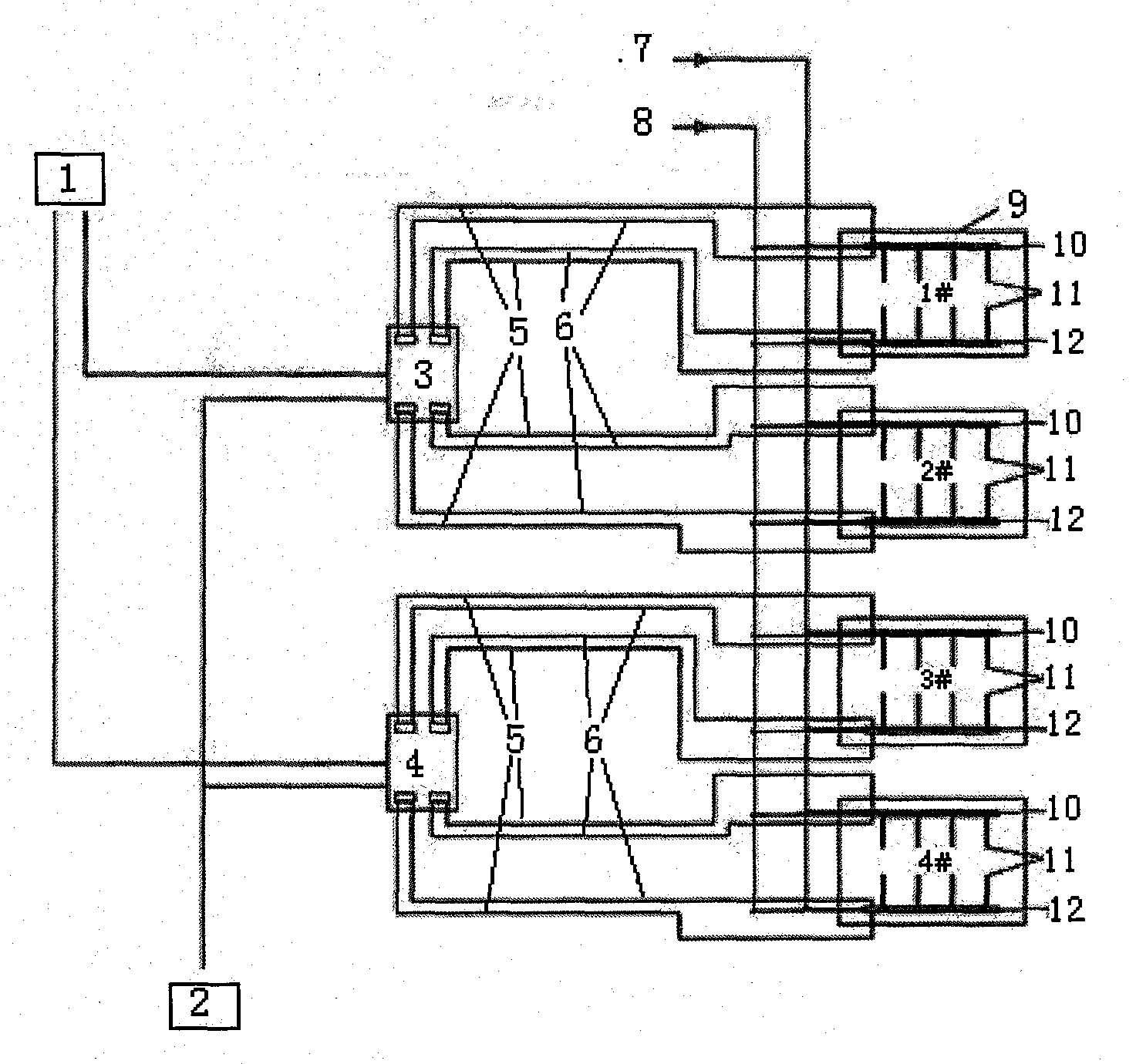

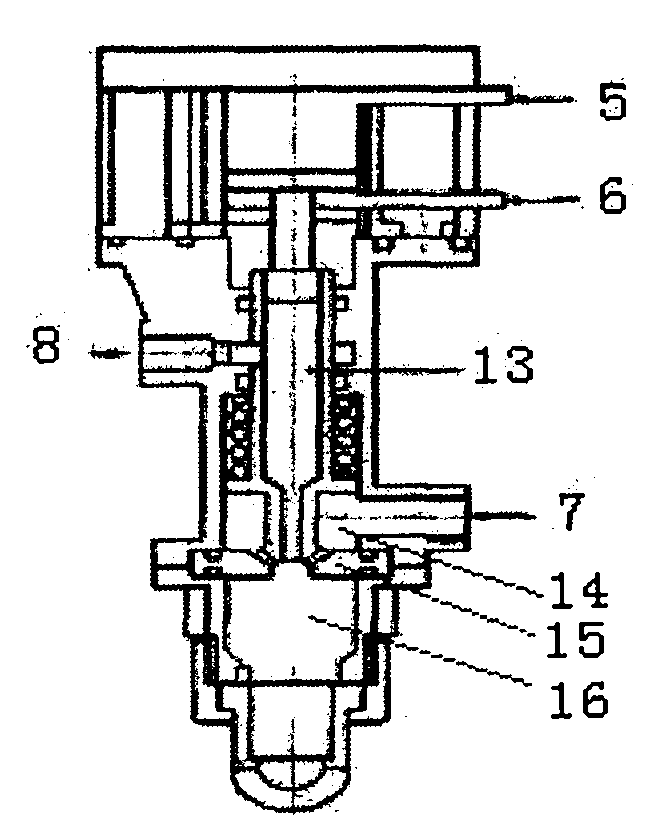

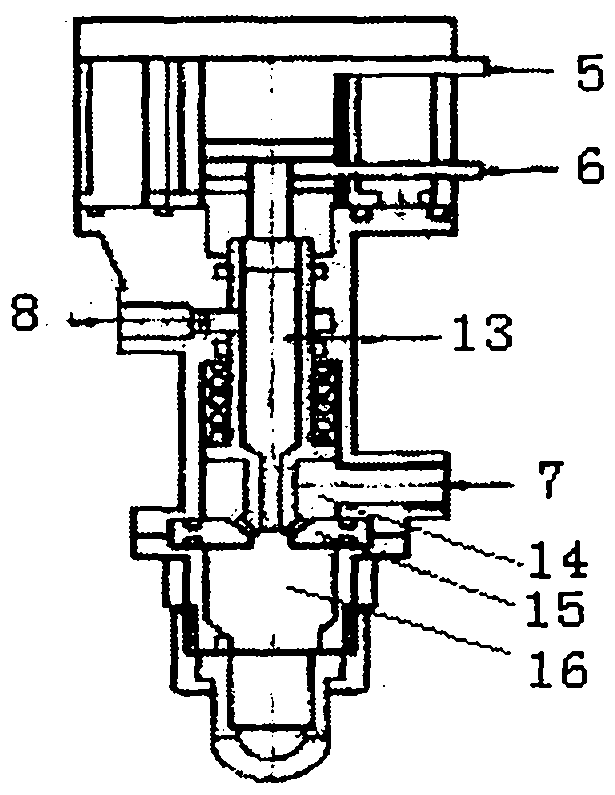

[0017] One set of controller and one set of electromagnetic distributor are installed in each section, and the gas circuit and water circuit are connected. Start pouring steel, the nozzle sprays normally, and the process parameters are: spray height 300mm, spray angle 110°, water pressure 0.2-0.3Mpa, spray pressure 0.1-0.2Mpa. Set the cleaning cycle to 30min and the cleaning time to 4s in the controller. When the steel pouring time reaches 30 minutes, the controller sends a start signal to the electromagnetic distributor, and the electromagnetic valves inside the electromagnetic distributor start sequentially, the compressed air control pipeline 6 on the upper part of the nozzle enters the compressed air, the compressed air control pipeline 5 exhausts, and the piston moves upward. The movement lifts up the diversion core, the supply of atomizing gas is cut off, the distance between the lower part of the diversion core and the spacer is pulled to 3mm, and the impurity is instan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com