Preparation method and application of coagulated sludge-based granular filler used for water treatment

A granular filler and water treatment technology, applied in the field of water treatment, can solve the problems of limited application, achieve strong cation exchange capacity, good removal effect, and low risk of leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

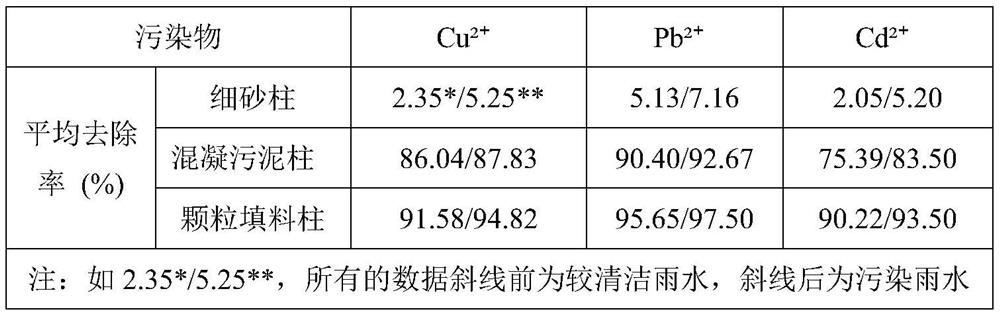

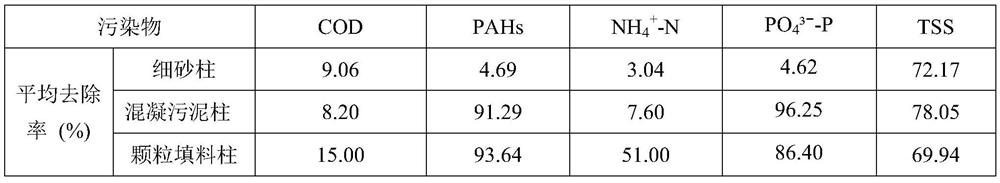

Examples

Embodiment 1

[0025] 1) Dry the coagulation sludge, bentonite and corn cobs from the water purification plant at 60°C in an electric heating constant temperature blast drying oven, and grind all raw materials into powder with a grinder and pass through a 100-mesh sieve to obtain powdery raw materials, granules Diameter <0.15mm; the coagulation sludge comes from the surface water purification plant, and polyaluminum chloride (PAC) is used for coagulation treatment; bentonite is a conventional product of chemical plants, and there is no strict requirement on purity.

[0026] 2) uniformly mixing the coagulation sludge, bentonite and corncob powder after the treatment in step 1) according to the ratio of 3:2:1 by mass, adding an appropriate amount of water and stirring evenly to form a viscous mixture;

[0027] 3) preparing the viscous mixture prepared in step 2) into granules with a diameter of 5-6mm by rolling granulation to obtain a composite granule base;

[0028] 4) Drying the composite pa...

Embodiment 2

[0051] The difference between this example and Example 1 is that the mass ratio of coagulated sludge, bentonite and corn stalk powder is 6:3:1, and the granular filler is prepared by pressure granulation, and the remaining operation steps are the same as those in the example 1 is the same.

[0052] The strength of the granular filler obtained in this example is 0.43Mpa, and there is no risk of ecotoxicity. The static adsorption capacity of the granular filler for phosphorus is 11.49mg-P g -1 , the static adsorption capacity of the representative heavy metal lead is 11.87 mg g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com