Preparation method of MnO2/Fe3O4 compound adsorbent

A composite adsorption and static sedimentation technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult separation, and achieve the effect of easy operation and simple separation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: MnO in this embodiment 2 / Fe 3 O 4 The preparation method of the composite adsorbent is carried out according to the following steps: 0.45mol FeSO 4 ·7H 2 O was dissolved in 200mL of ionized water, and then placed in the anaerobic operating table, and then 1.2mol NaOH was added. After the blue-green flocculation appeared, the glass rod was quickly stirred and mixed, and then poured into the 0.1molKMnO 4 In the beaker, stir until KMnO 4 When completely dissolved, let it settle for 1~2h, filter out the supernatant, rinse the precipitate repeatedly with deionized water until the washing liquid becomes neutral, then place the precipitate in a vacuum drying oven at 40-60℃ Dry for 5-7h, grind into powder form to obtain MnO 2 / Fe 3 O 4 Composite adsorbent.

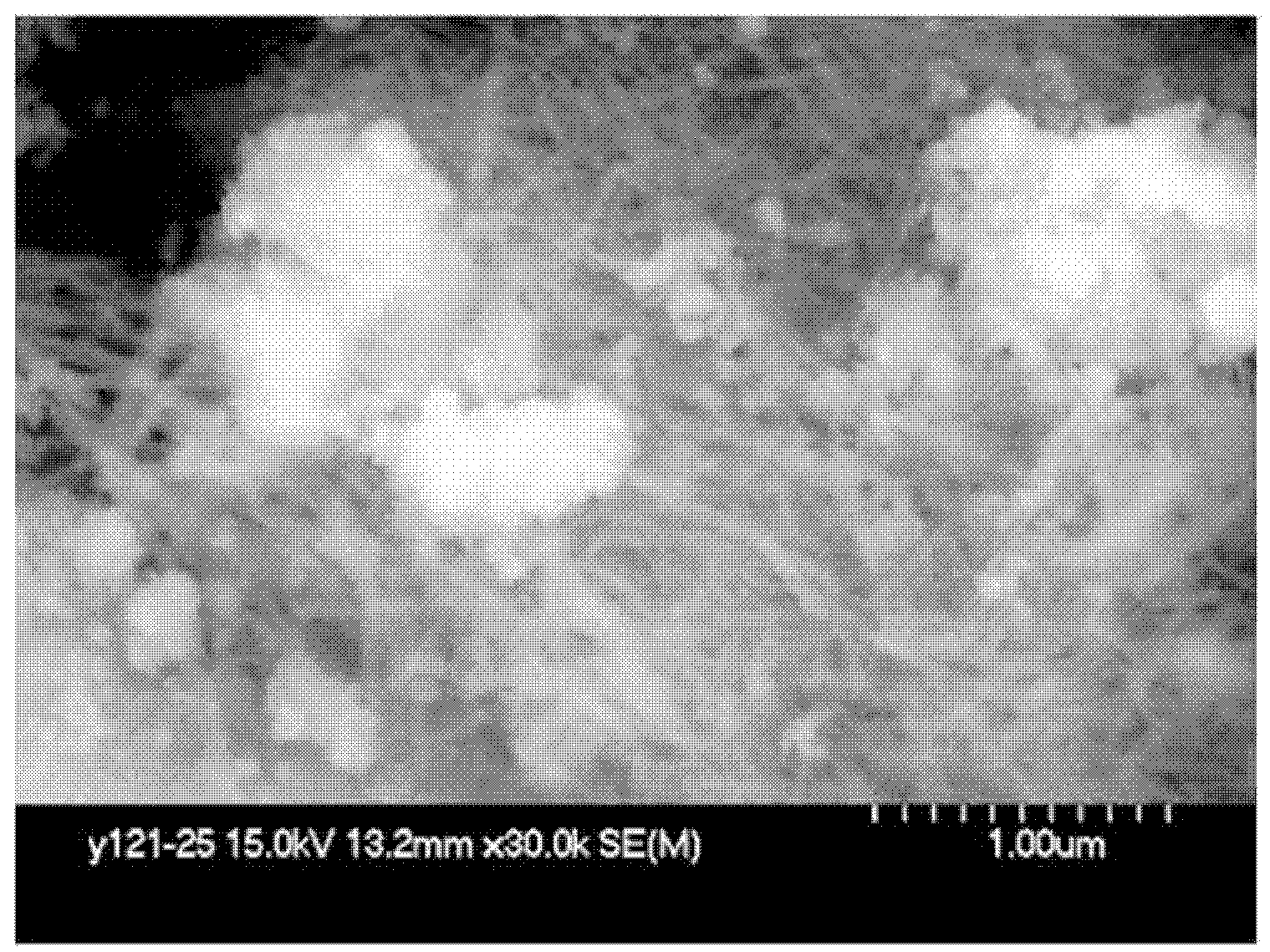

[0009] MnO in the composite adsorbent prepared by the method of this embodiment 2 The distribution is relatively uniform, the particle size distribution ranges from 1 to 100μm, and the manganese dioxide i...

specific Embodiment approach 2

[0010] Specific embodiment two: this embodiment is different from specific embodiment one in that the quiet time is 1h. The other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the drying temperature is 50°C. The other steps and parameters are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com