Manufacturing method of high-definition gravure wood grain printing plate roller

A production method and printing plate roller technology, applied in printing, printing plate preparation, etc., can solve the problems of difficulty in fine layers, loss of definition, low image input scanning resolution, etc., to achieve enhanced performance of fine layers and compensation for clarity Loss, the effect of guaranteeing the tone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated by the following examples.

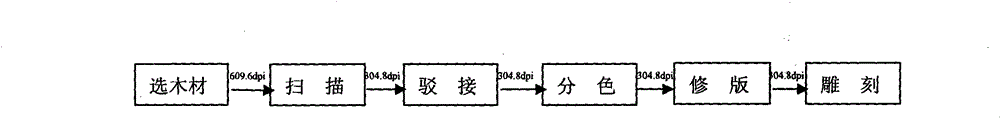

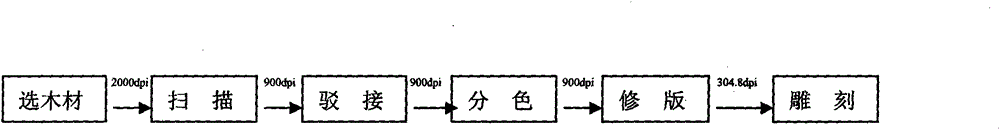

[0020] see figure 2 Shown, a kind of manufacturing method of high-definition gravure wood grain printing plate roller, its process steps are as follows:

[0021] (1) Select a group of cherry solid wood boards with a thickness of 10mm and clear texture and fine texture as the scanning manuscript, and perform special treatments such as polishing and oiling on the surface to achieve clarity and smoothness, which is convenient for scanning.

[0022] (2) Place the originals horizontally one by one on the scanner platform, and accurately measure the height of the originals. Choose a high-definition 120mm lens, adjust the lens distance to about 52cm to make it focus. Input the resolution of 2000dpi on the control panel, adjust the light source, set the exposure time to 44ms, select the color depth to 24bit, and start the scanner to scan in batches. This enables clear, high-precision information data t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com