High-volume fly ash cement production technique and pulverizing technique

A technology of fly ash cement and fly ash, which is applied in cement production, clinker production, etc., can solve the problems that the chemical activity is not fully exerted, the strength of cement cannot meet the standard requirements, and achieve economic benefits and social benefits. Significant benefits, improved grinding efficiency, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

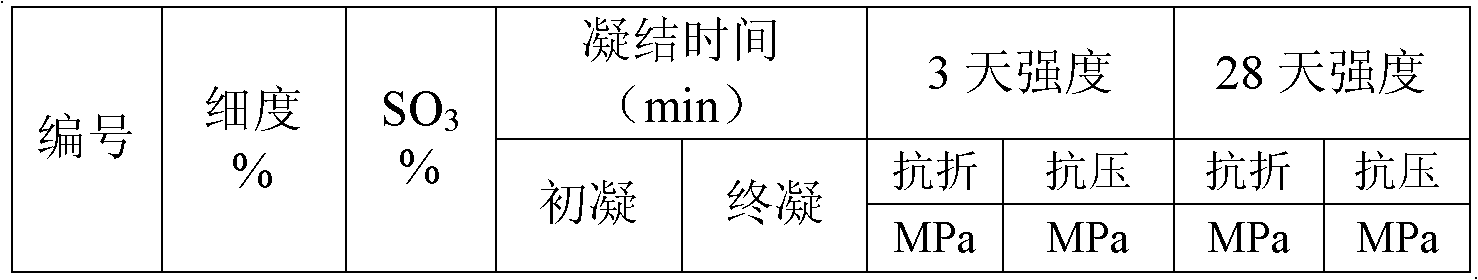

[0028] Embodiment 1 Production of high-mixed fly ash cement and its properties by the method of the present invention

[0029] Raw material preparation: 10% of sodium carbonate, 88% of sodium sulfate, and 2% of triethanolamine are mixed evenly for the activator according to the weight ratio. The clinker comes from Panzhihua Ruifeng Cement Co., Ltd., which is produced by the raw material preparation and clinker calcination process according to the ordinary cement production method. The clinker meets the national standard GB / T 21372-2008; the fly ash comes from Pangang gangue power generation Co., Ltd. meets the national standard GB / T 1596, and the gypsum comes from Panzhihua Pingdi Gypsum Factory, which meets the national standard GB / T 5483.

[0030] First weigh the clinker and gypsum according to the mass shown in Table 1, mix them and grind them for more than 30 minutes, so that the specific surface area of the clinker and gypsum mixture is greater than 350m 2 / kg, the res...

Embodiment 2

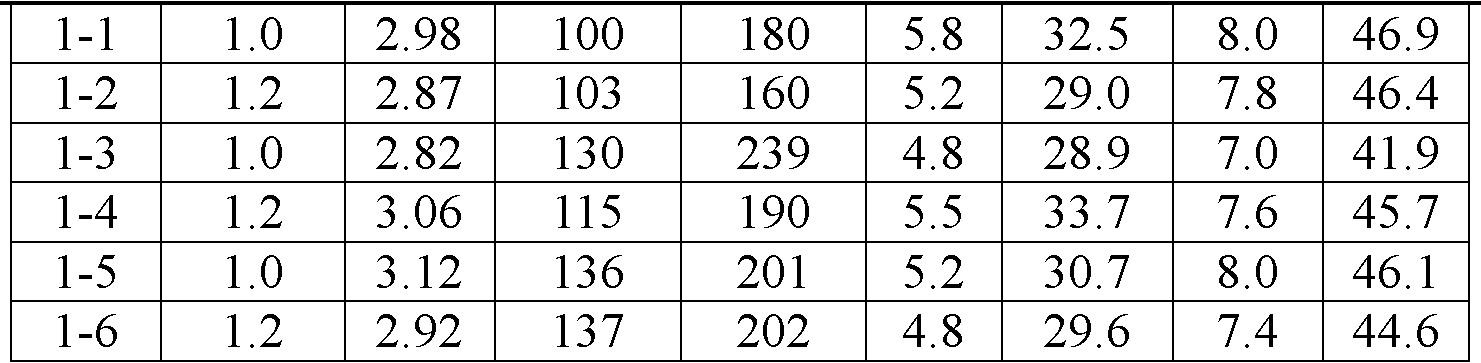

[0037] Embodiment 2 Production of high-mixed fly ash cement and its properties by the method of the present invention

[0038] Raw material preparation: 10% of sodium carbonate, 88% of sodium sulfate, and 2% of triethanolamine are mixed evenly for the activator according to the weight ratio. The clinker comes from Panzhihua Ruifeng Cement Co., Ltd., which is produced by the raw material preparation and clinker calcination process according to the ordinary cement production method. The clinker meets the national standard GB / T 21372-2008; the fly ash comes from Pangang gangue power generation Co., Ltd., which meets the national standard GB / T 1596; the gypsum comes from Panzhihua Pingdi Gypsum Plant, which meets the national standard GB / T 5483; the slag comes from Panzhihua Tongde Steel Works, which meets the national standard GB / T 203.

[0039] First weigh the clinker, gypsum and slag according to the mass shown in Table 3, mix them and grind them for more than 30 minutes, so th...

Embodiment 3

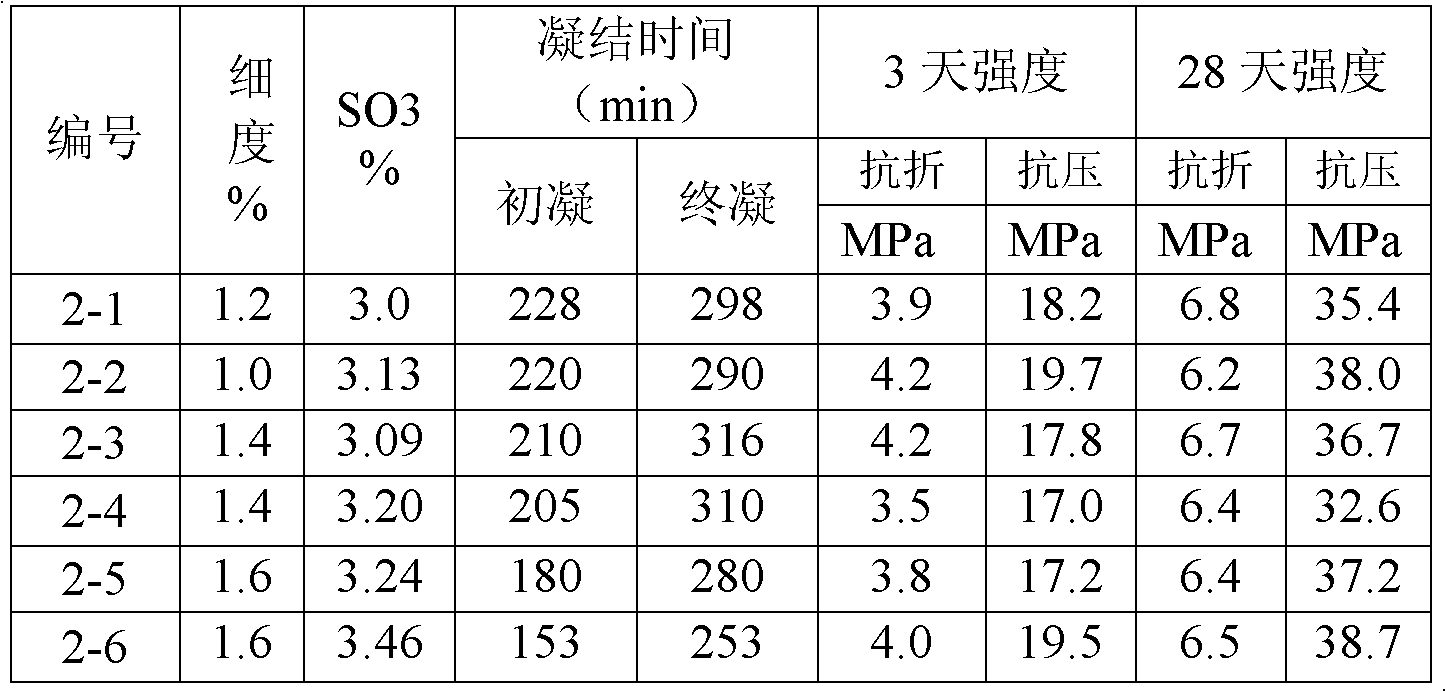

[0045] Embodiment 3 Production of high fly ash cement and its properties with the grinding method of the present invention (without the activator described in the present invention in the raw material)

[0046] Raw material preparation: The clinker comes from Panzhihua Ruifeng Cement Co., Ltd., which is obtained through the raw material preparation and clinker calcination process according to the ordinary cement production method. The clinker meets the national standard GB / T 21372-2008; the fly ash comes from Panzhihua Coal Gangue Power Generation Co., Ltd. meets the national standard GB / T 1596, and the gypsum comes from Panzhihua Pingdi Gypsum Factory, which meets the national standard GB / T 5483.

[0047] First weigh the clinker and gypsum according to the mass shown in Table 5, mix them and grind them for more than 30 minutes, so that the specific surface area of the clinker and gypsum mixture is greater than 350m 2 / kg, the residue on 0.08mm square hole sieve is less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com