Rubber asphalt modifier and production method thereof

A technology of rubber asphalt and production method, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of complex production process, adverse environmental impact, and high cost, and achieve the effect of simplifying the process, simple production operation, and alleviating environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The rubber asphalt modifier of the present invention is characterized in that its components and parts by weight are rubber powder: 80-85, and Vestenamer rubber additive: 15-20.

[0015] The production method of described asphalt rubber modifier, is characterized in that, comprises the following steps:

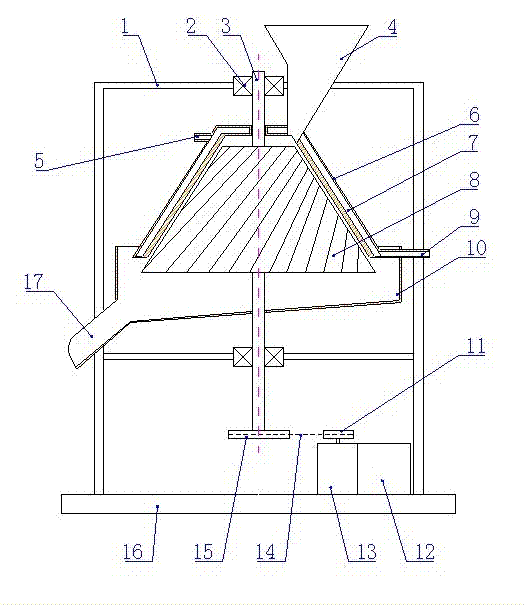

[0016] (1) Mix rubber powder and chemical raw material Vestenamer rubber additive in a weight ratio of 8:2, add it to a steel mill with a cooling device, and grind it. The working temperature is lower than 80°C to prevent aging. The ground binary mixture is not larger than 60 mesh.

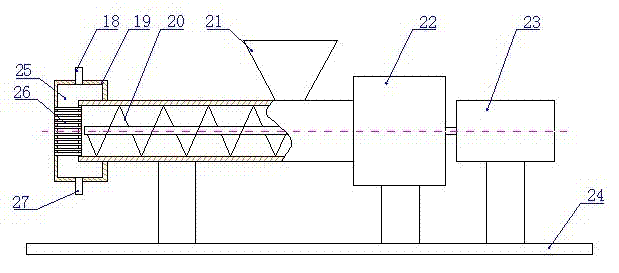

[0017] (2) Extrude the multi-component mixture into irregular particles with a particle size of 3 to 6 mm with a shaping granulator,

[0018] In the present invention, the chemical material Vestenamer is used as the modified material of rubber powder and asphalt, and the rubber powder is mixed together according to the optimal ratio to form a rubber asphalt modifier that is directly applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com