Composite road surface intensifier and production method thereof

A composite pavement and production method technology, which is applied in the field of composite pavement enhancers to achieve the effects of low cost, simple production and operation, and strong anti-rutting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

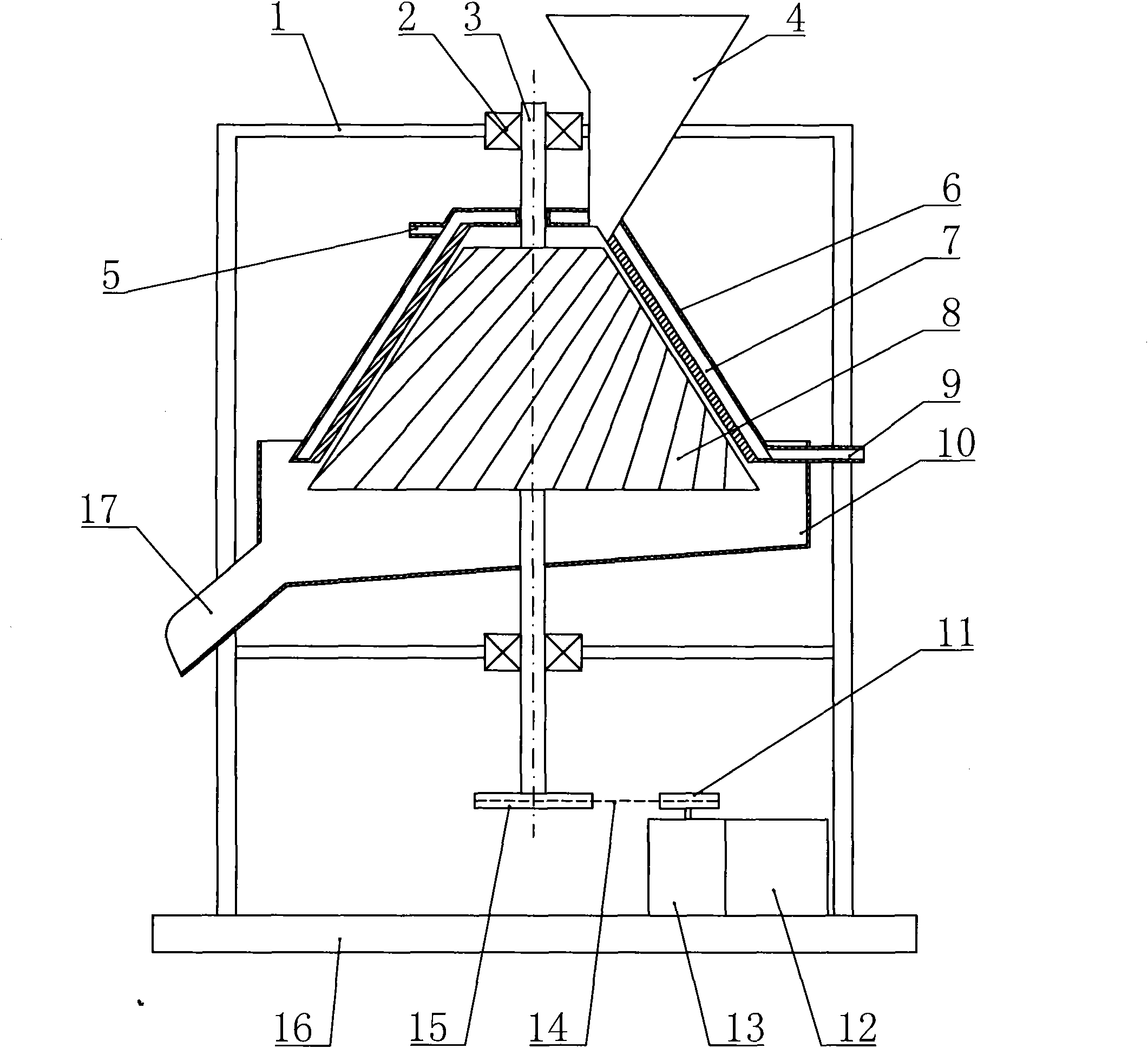

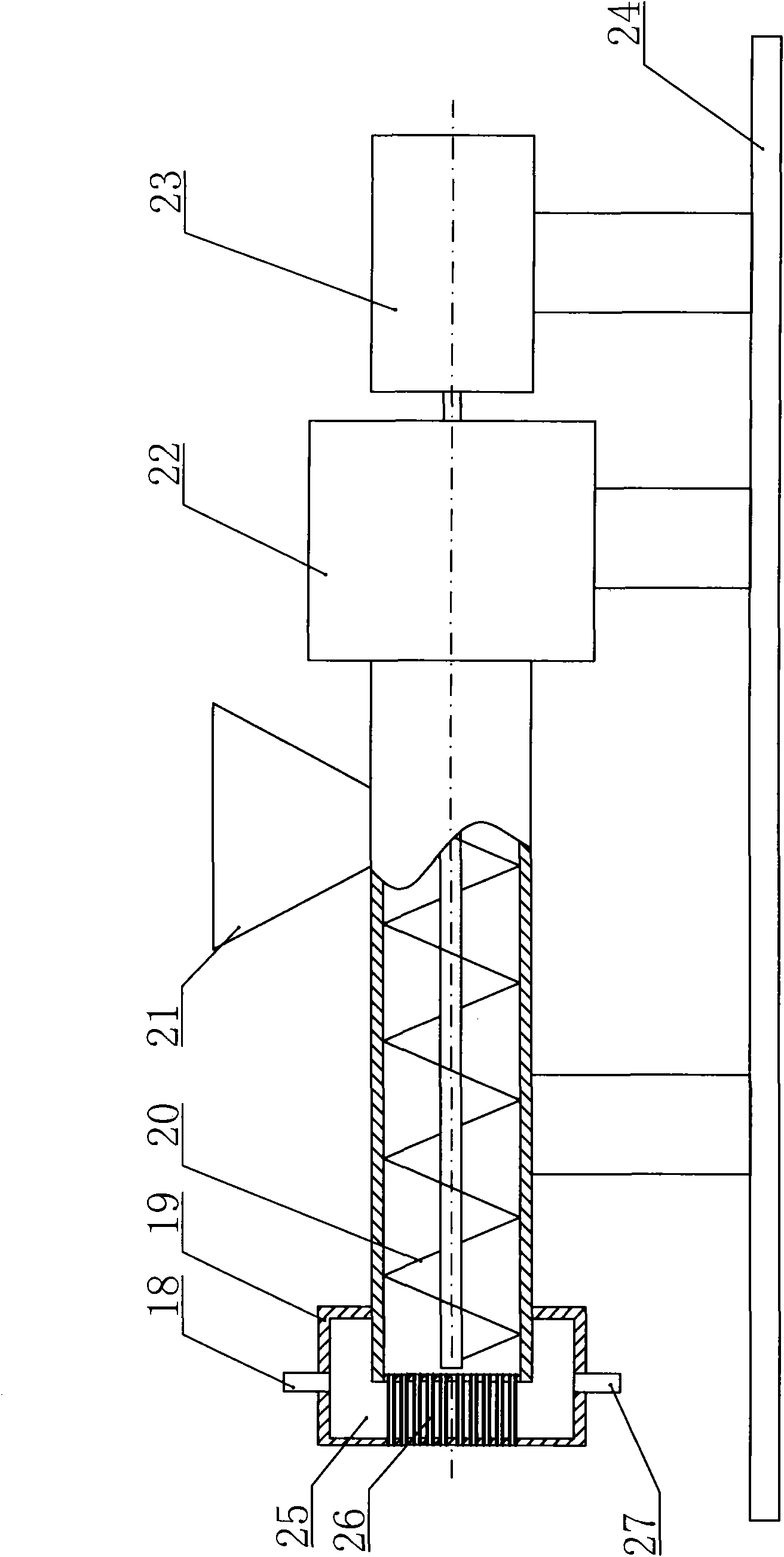

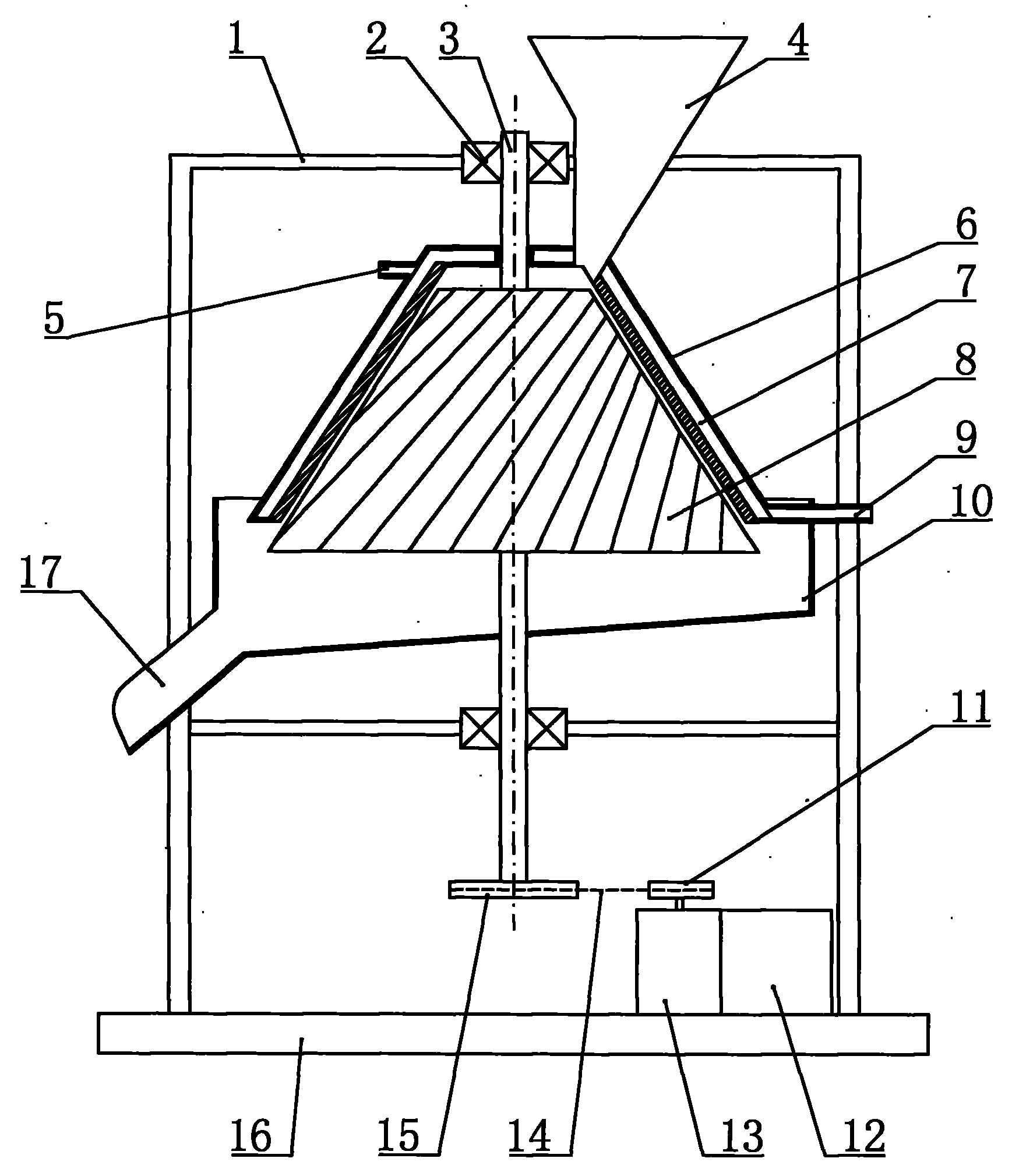

Method used

Image

Examples

Embodiment Construction

[0016] A composite pavement reinforcing agent of the present invention is characterized in that its components and parts by weight are respectively PE: 29-34, rock asphalt: 10-16, rubber powder 13-21, diatomite 2-4, carbon dioxide Silicon 4-8 and original lignin 27-37. PE and rock asphalt wherein can improve the various properties of asphalt pavement as modifying agent; Described rubber powder and diatomite are as reinforcing agent, improve the intensity and anti-rutting performance of asphalt pavement; Described silicon dioxide and Original lignin acts as a stabilizer to prevent asphalt aging and increase the service life of asphalt pavement.

[0017] The production method of described composite pavement reinforcing agent is characterized in that, comprises the following steps:

[0018] (1) Mix granular PE and rubber powder in a weight ratio of 7:3, put them into a steel mill with a cooling device, and pulverize them. The working temperature is lower than 60°C to prevent agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com