Method and system for measuring noise frequency response function

A technology of frequency response function and measurement method, which is applied to vibration measurement in solids, measurement vibration, and measurement devices, etc., can solve the problems of inability to test the noise characteristics of parts alone, cumbersome insertion loss test methods, and complicated operations, etc., to achieve test The method is reasonable and simple, the development cycle is shortened, and the equipment structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

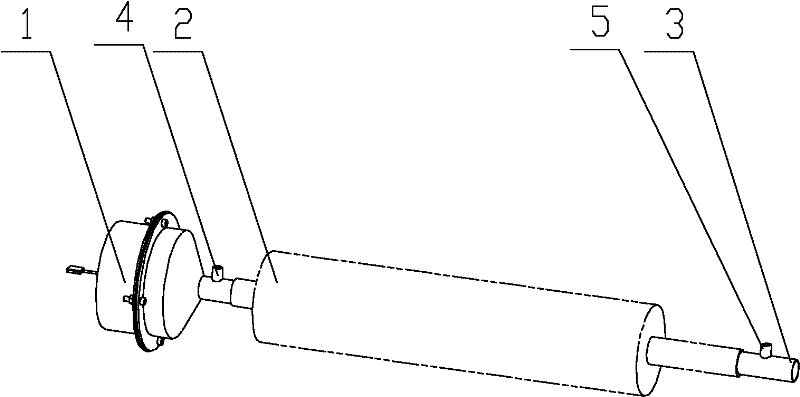

Embodiment 1

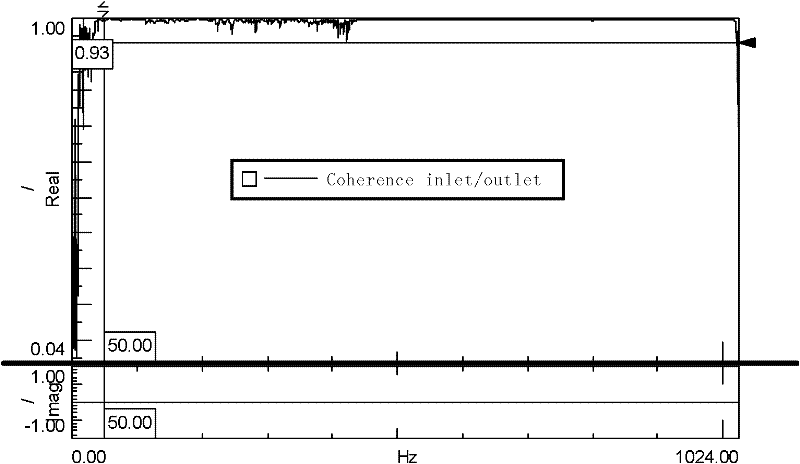

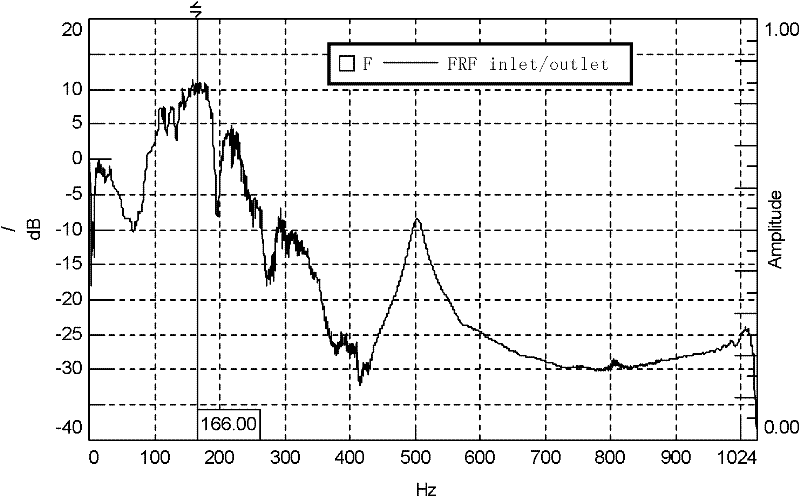

[0021] Embodiment 1: is a kind of such as figure 1 The measurement method and measurement process of the measurement system of the noise frequency response function are shown. The present invention proposes a new test method, which measures the sound pressure at the inlet and outlet of the tested part, and performs a ratio operation on the sound pressure to obtain the frequency response function curve of the tested part. From the frequency response function curve, it can be seen that the measured part noise characteristics. This embodiment uses the following equipment: noise data acquisition system, microphone for measuring noise signals, notebook or other computers with noise software installed, power amplifier, excitation sound source, tailpipe. The noise software used in this embodiment is conventional noise software provided by Chery Automobile Co., Ltd., and its software name is RFR test.9A. The output of the noise data acquisition system is connected to the input of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com