Detecting device for detecting lateral pressure of great-mobility concrete template

A concrete formwork and testing device technology, applied in the direction of measuring fluid pressure, measuring devices, material inspection products, etc., can solve the problems of inaccurate measurement results, large amount of concrete, limited pouring height, etc., and achieve reliable work, easy operation, and measurement fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

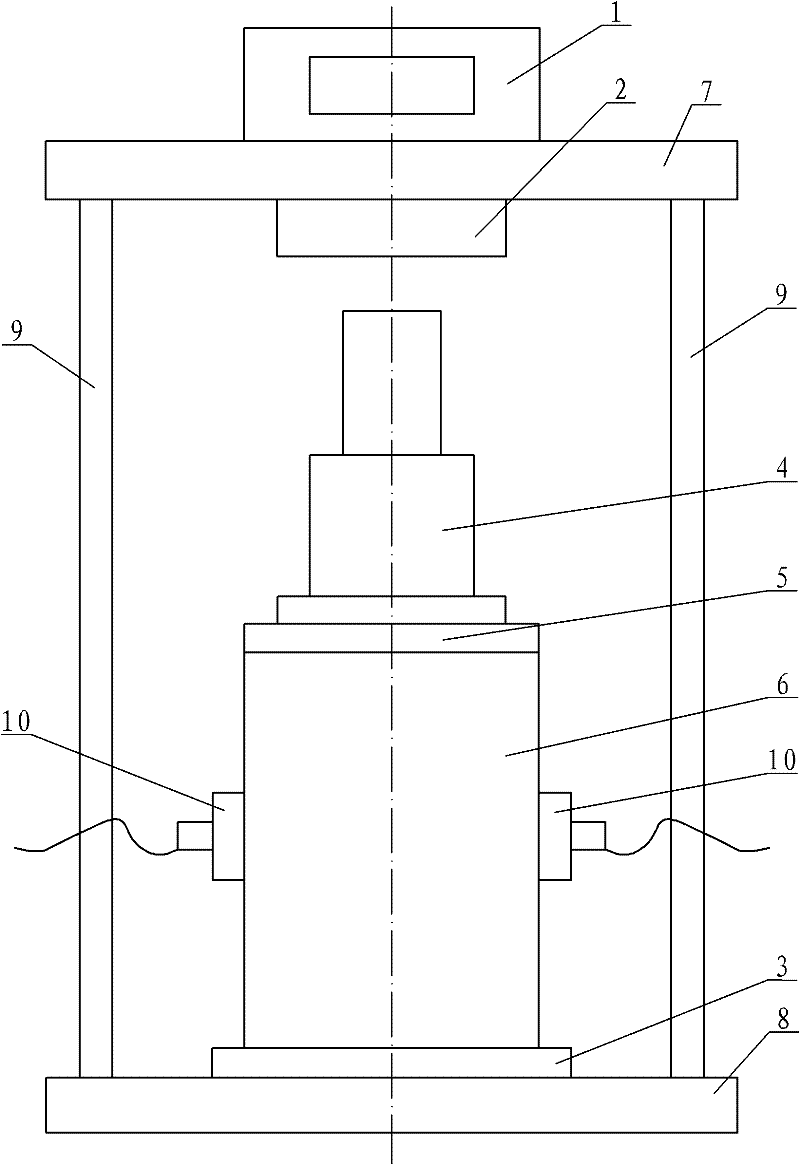

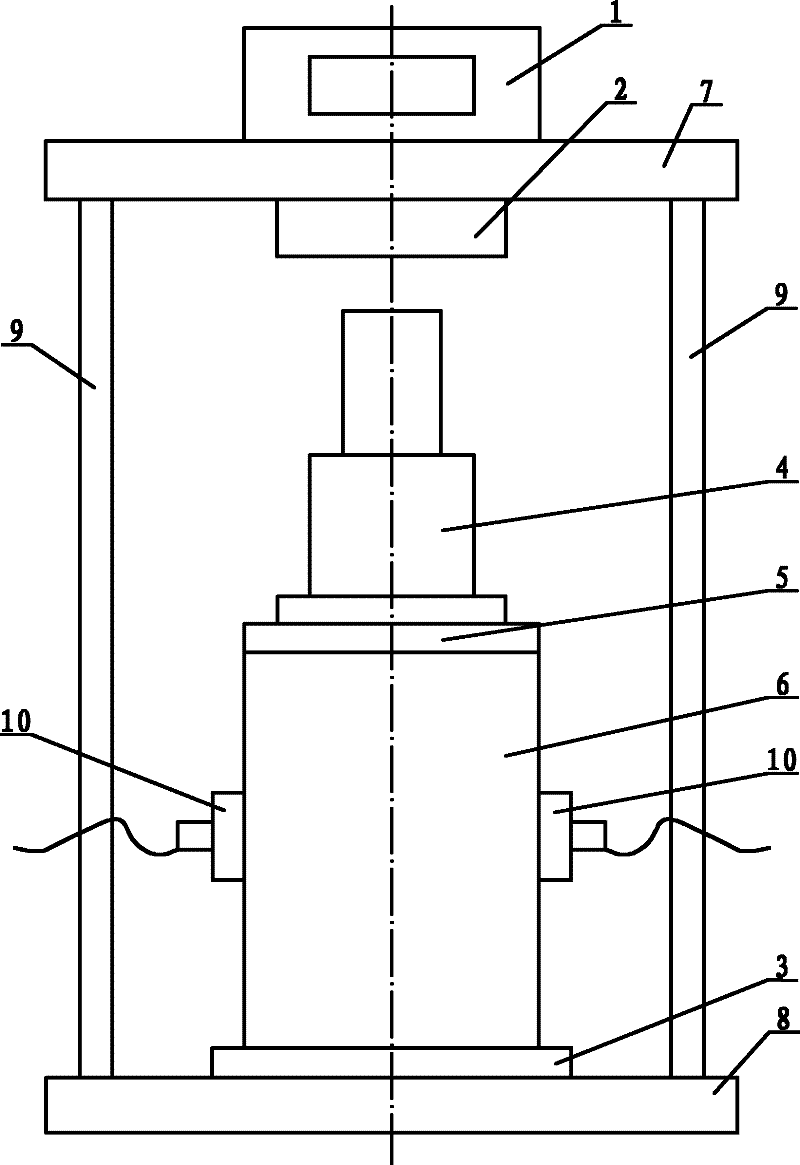

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a data acquisition and display instrument 1, a pressure sensor 2, a steel cylinder chassis 3, a screw jack 4, a steel cylinder sealing piston 5, a circular steel cylinder 6, an upper plate 7, a lower plate 8, two The pillar 9 and the two pressure sensors 10, the upper plate 7 and the lower plate 8 are arranged up and down, and the two pillars 9 are symmetrically arranged between the upper plate 7 and the lower plate 8 relative to the center line of the upper plate 7 and the lower plate 8, and The two pillars 9 are fixedly connected to the corresponding upper plate 7 and the lower plate 8 respectively, the steel cylinder chassis 3 is arranged on the upper end surface of the lower plate 8, and the steel cylinder chassis 3 is fixedly connected to the lower plate 8, and the circular steel cylinder 6 is arranged on the On the upper end surface of the steel cylinder chassis 3...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To describe this embodiment, the vertical centerline of the pressure sensor 2 , the vertical centerline of the screw jack 4 and the vertical centerline of the circular steel cylinder 6 in this embodiment are on the same straight line. This design can ensure accurate test results. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 The present embodiment will be described. In this embodiment, the diameter of the inner cavity of the circular steel cylinder 6 is 200 mm, and the height of the circular steel cylinder 6 is 400 mm. When the circular steel cylinder 6 is the above value, it is the best value for quickly and accurately measuring the side pressure of the large fluidity concrete formwork. Other components and connections are the same as those in the first embodiment.

[0011] Working process of the present invention:

[0012] 1), check whether the connection between the circular steel cylinder 6 and the steel cylinder chassis 3, and the two pressure sensors 10 and the circular steel cylinder 6 is tight, so as to ensure that the circular steel cylinder 6 does not leak;

[0013] 2), put the mixed concrete into the circular steel cylinder 6 in two layers, and manually vibrate to make the concrete dense, and then cover the steel cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com