Method for reducing the pulp content of fruit juices containing pulp

A pulp and juice technology, applied in the field of pulp content in citrus juices, can solve the problem that transparent liquid phase measurement is not fully reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

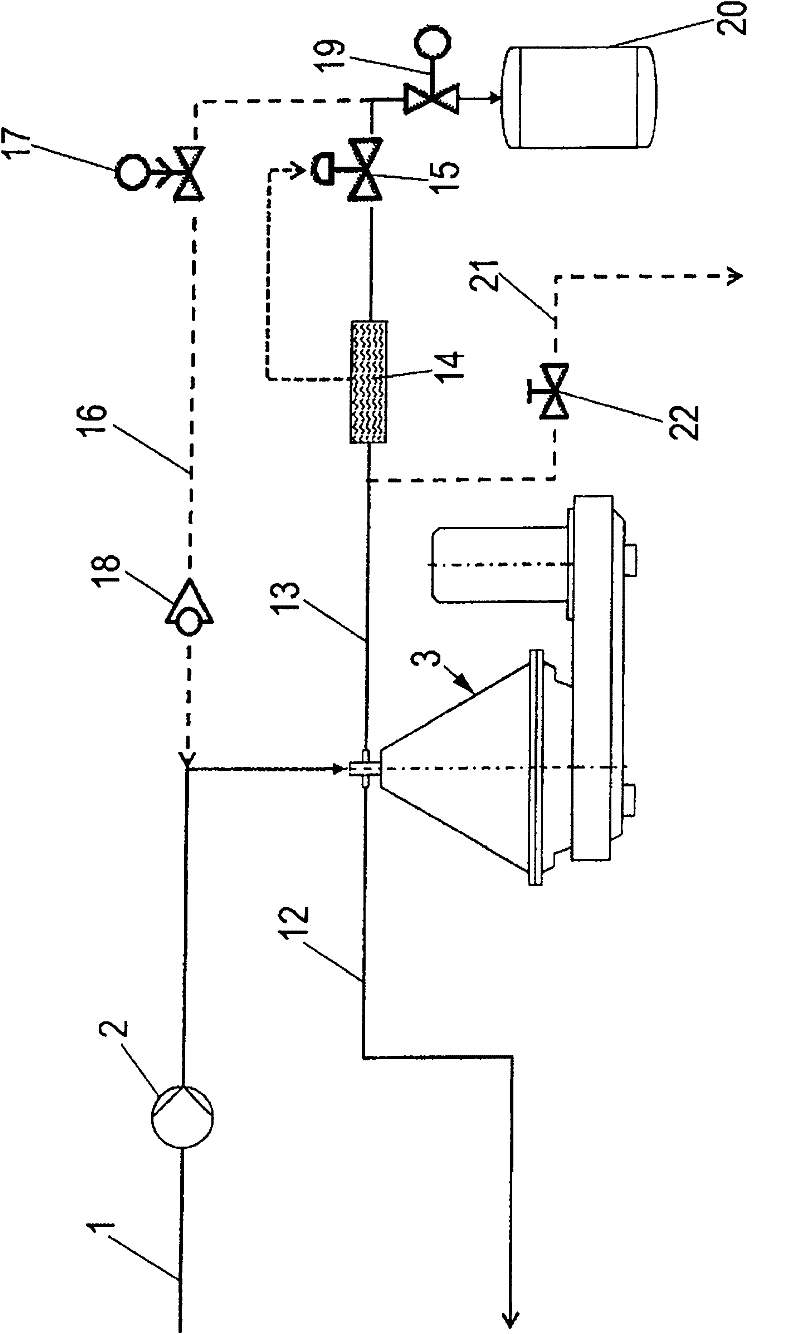

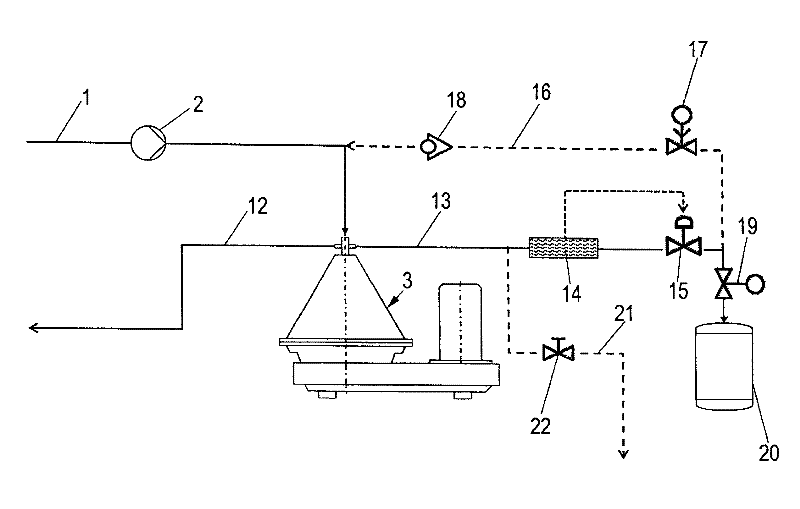

[0036] according to figure 1 , the citrus fruit juice with the pulp content that needs to be reduced is introduced through an input pipeline 1 at figure 1 In the drum of the disc separator 3 shown schematically by Zhongchun, a pump 2 can be connected in the supply line 1 . The disc separator 3 clarifies fruit juice, preferably citrus fruit juice, wherein the pulp phase containing pulp is continuously output through a first output device and the clarified juice is continuously output through a second output device.

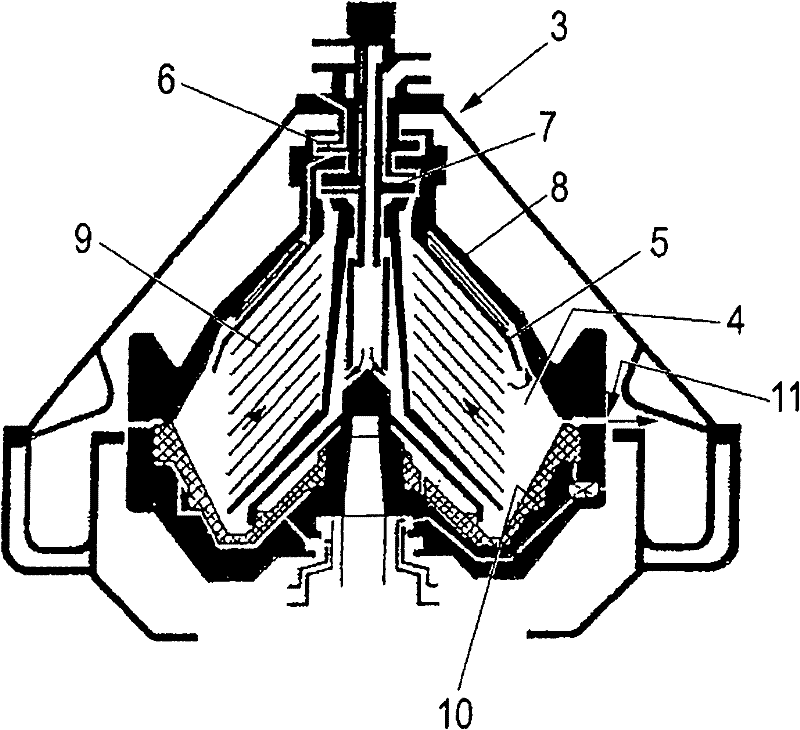

[0037] When the pulp phase (see figure 2 ) is collected in the solids collecting chamber 4 of the separator and passes through the separating disc 5 as a viscous, high-solids-containing, but still flowable phase during operation and as the first output device—that is, the output itself for the output of the liquid The scraper disc 6 of the device is output, while the clarified citrus juice is output as a mobile, lighter phase through another scraper disc 7 as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com