Cylindrical filter press

A filter press and cartridge type technology, applied in the field of filter presses, can solve the problems of unfavorable high-efficiency production, small space for effective use of filter press, troublesome filter plate cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

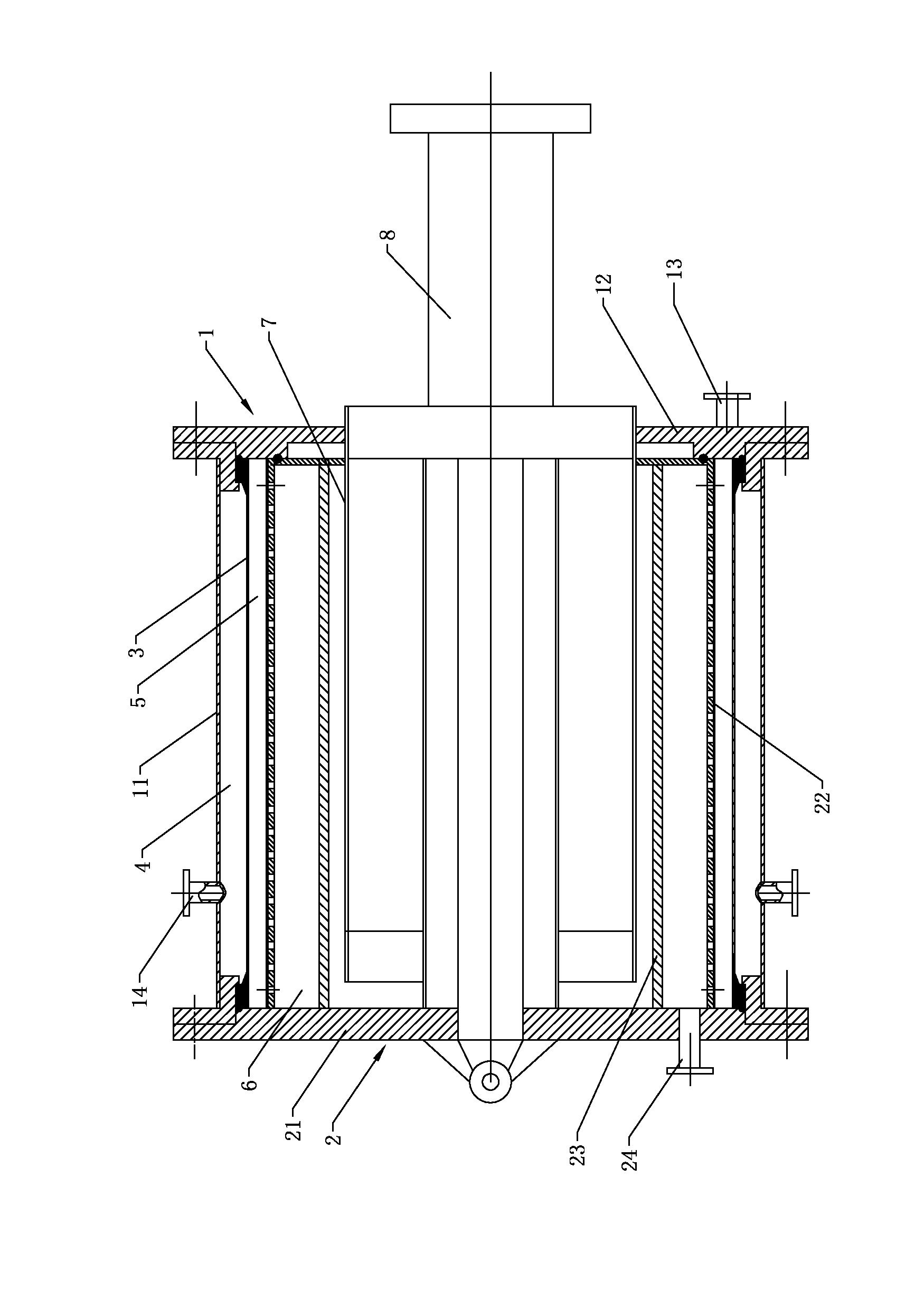

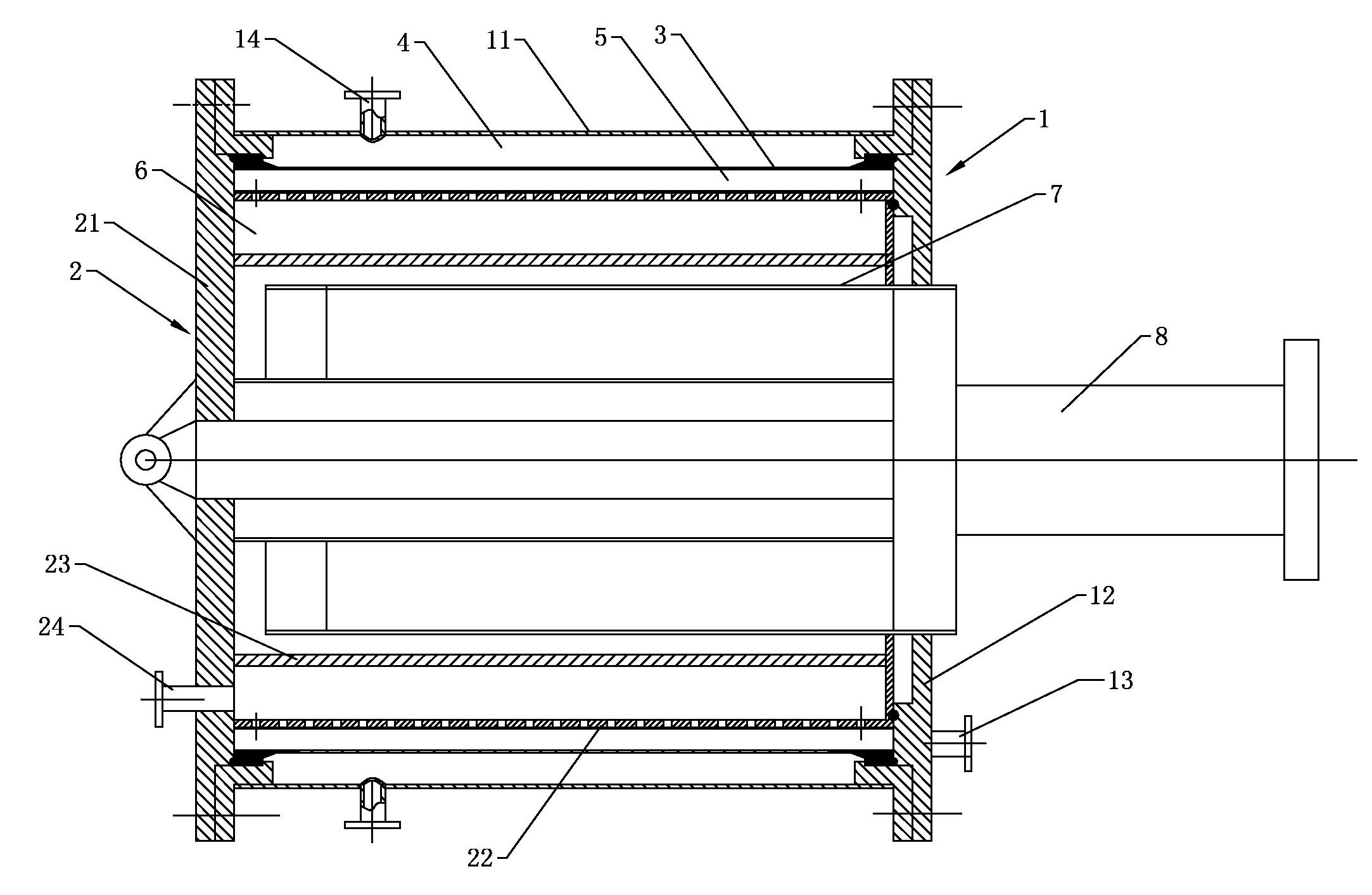

[0019] A cylindrical filter press, as shown in the accompanying drawings, is characterized in that it includes an outer cylinder 1 and an inner filter cylinder 2, and the inner filter cylinder 2 is axially slidably fitted in the inner cavity of the outer cylinder 1. The outer circumference of the cylinder wall of the inner filter cartridge 2 is provided with a filter hole and is wrapped with a filter cloth outside. The inner cavity wall of the outer cylinder 1 is provided with an expandable tension membrane 3, and the tension membrane 3 is connected to the inner filter cylinder 2. An annular airtight material filter cavity 5 is formed between the cylinder walls of the outer cylinder, and an annular airtight force application chamber 4 is formed between the tension film 3 and the cylinder wall of the outer cylinder 1, and the outer cylinder 1 is provided with a force application chamber 4 connected force medium inlet 14 and force medium outlet, and a feed port 13 communicated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com