Tail gas purification treatment device

A treatment device and exhaust gas purification technology, which is applied in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve the problem of unsatisfactory spraying effect of spray device, unsatisfactory mist trapping effect of mist catcher, and inability of water mist and exhaust gas. Contact mixing and other problems, to achieve the effect of simple structure, saving waste and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

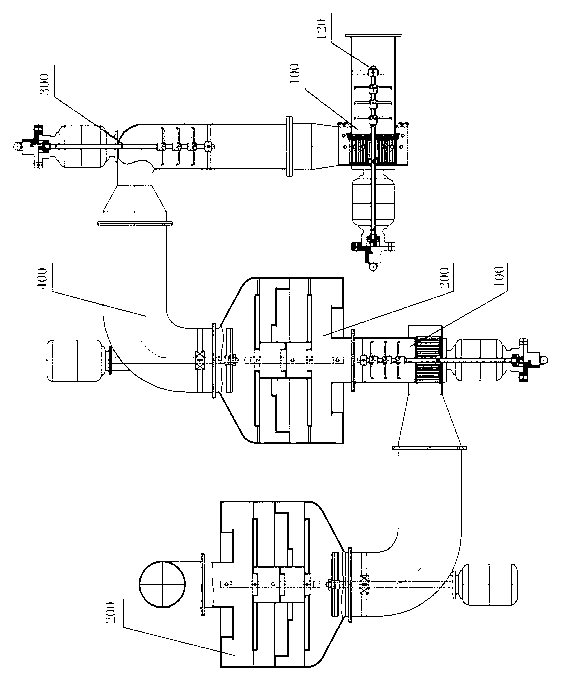

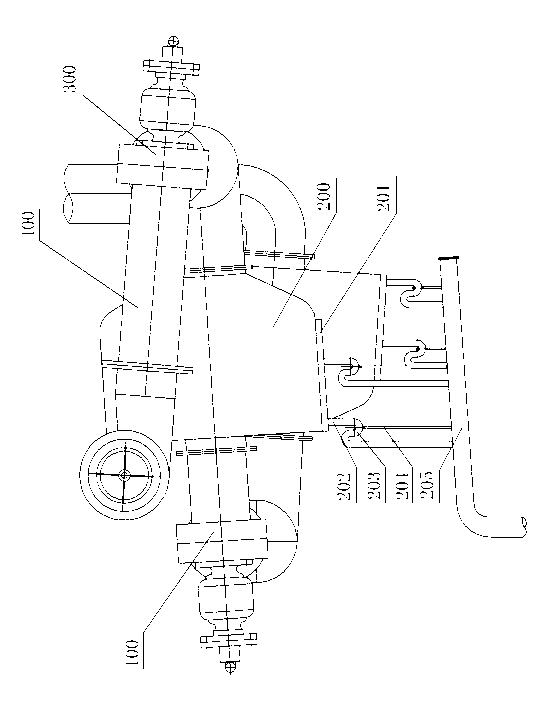

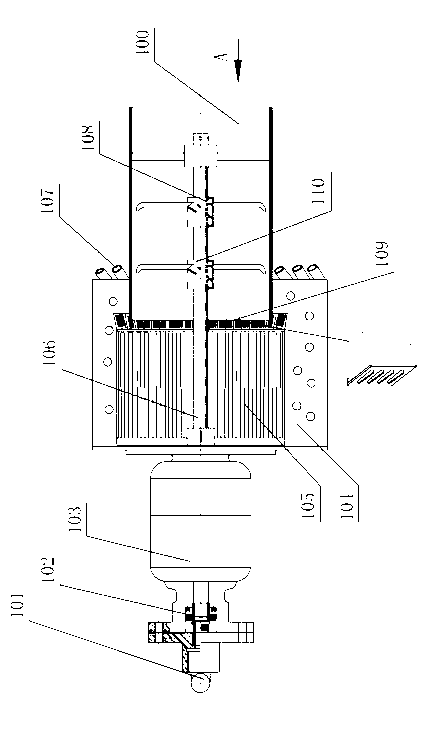

[0024] like figure 1 , figure 2 As shown, the present invention is a tail gas purification treatment device, which includes an exhaust pipe 400 and at least one spray device 100 and at least one fog-eliminating friction precipitation device 200 arranged at intervals in sequence on the exhaust pipe 400, between the spray device 100 and One or more auxiliary spraying devices 300 may also be installed between the fog-eliminating and friction-precipitating devices 200 according to the size of the exhaust gas discharge. In the present invention, the first spray device 100, the auxiliary spray device 300, the first fog-eliminating friction precipitation device 200, the second spray device 100 and the second fog-elimination friction precipitation device 200 are sequentially arranged at the air inlet of the exhaust pipe 400, And its exhaust pipe 400 is gradually lowered from the air inlet to the air outlet, which is more conducive to the discharge of condensed water after precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com