Flattening production process of stainless steel

A production process, stainless steel technology, applied in the leveling production process of stainless steel, in the field of T4003 stainless steel, can solve the problems of scratches, pits, and low production efficiency of T4003 leveling, and achieve the effect of eliminating defects and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

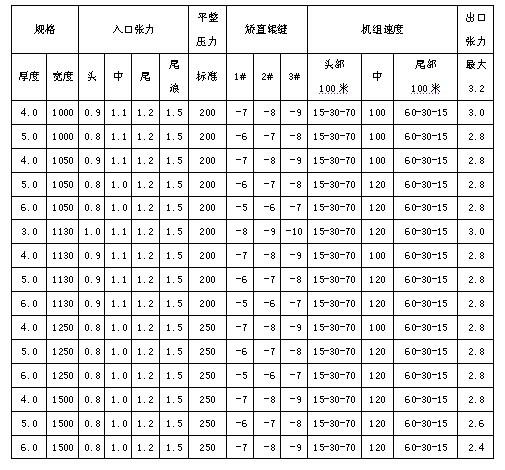

[0018] In this embodiment, the smooth surface is T4003 stainless steel with a width of 1130 mm and a thickness of 3.0 mm.

[0019] Step 1: First, check and confirm the channel of the skin-passing unit according to the following equipment flow. It is required that each roll rotates flexibly and has a smooth surface, and each transition plate is lower than the strip surface without deformation.

[0020] Step 2: Confirm the incoming material information including steel quality and specifications when loading, and perform head cutting at the preparation station to ensure that the steel coil can be smoothly loaded onto the uncoiler reel.

[0021] Step 3: After the steel coil enters the reel smoothly, press down the "pressure head roller" to confirm that the steel coil is in the center of the reel, and the inner loose steel coil is first tightened by the reel rotation.

[0022] Step 4: When leveling the first roll, first put in the "upper and lower roller wiper" to wipe the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com