Locating tool for frameworks/reinforced ribs of integrated composite-material wing structural member and application method of locating tool

A composite material and integral component technology, applied in workpiece clamping devices, manufacturing tools, etc., to improve assembly quality and meet assembly coordination requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

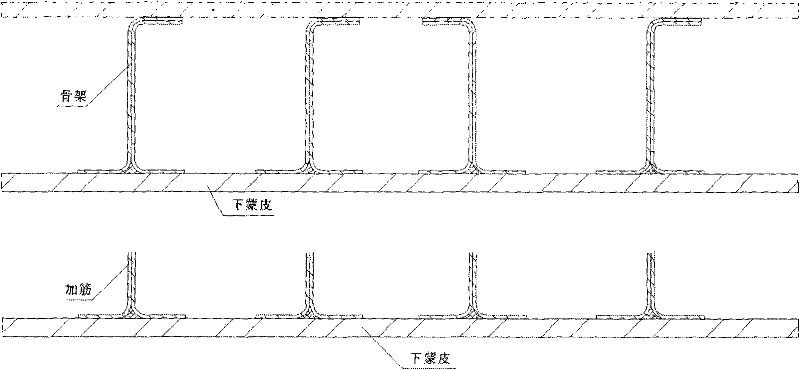

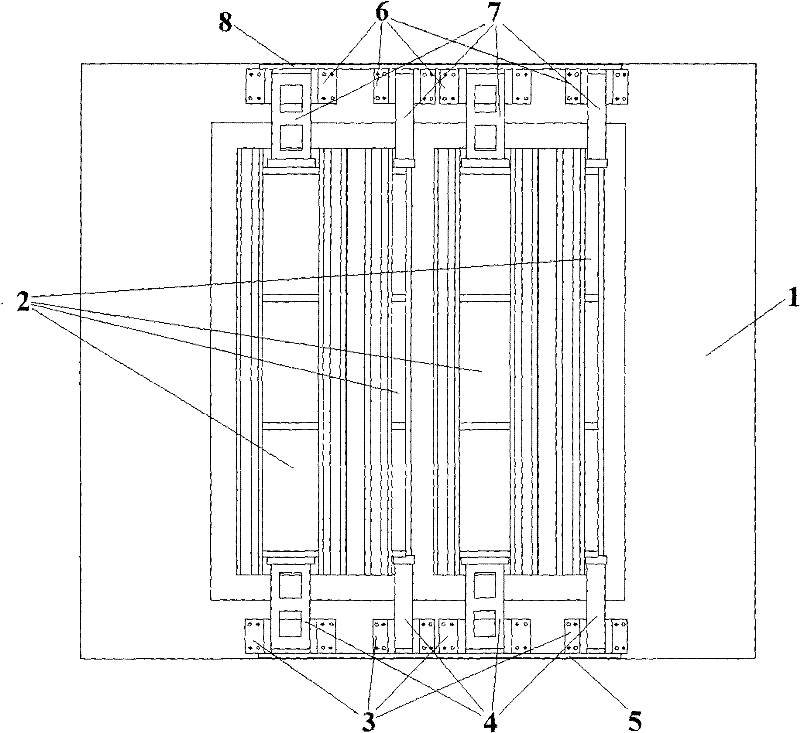

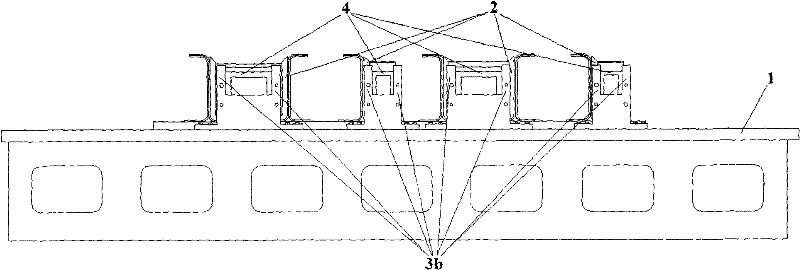

[0041] 1. A composite airfoil integral component with upper and lower skins. Between the upper and lower skins, there are 5 composite materials that are connected to the upper and lower skins. Type skeleton; positioning tooling for the composite wing surface integral component skeleton, including 1 skin mold made of steel and 5 skeleton curing molds. The shape of the skeleton curing mold is Shape, the skeleton curing mold is located Outside of the type frame, each The inner side of the mold skeleton is a [shaped soft mold, there are a total of 5 soft molds; on the skin mold there are skin profiles, on the skin profiles there are uncured skin blanks, on the uncured skin blanks There are 5 curing molds with skeleton blanks arranged; 5 wing root positioning devices and 5 wing tip positioning devices; the wing root positioning device is composed of 5 wing root positioning components and 1 wing root cross beam. The root positioning component consists of 1 wing root locator, 1 wing...

Embodiment 2

[0051] A composite wing surface integral wall panel with a lower skin. On the lower skin, there are 10 composite T-shaped reinforcements that only fit and connect with the lower skin; positioning tooling for the reinforcement of the composite wing surface integral component , Including 1 skin mold made of steel and 5 reinforced curing molds. The cross-sectional shape of the reinforced curing mold is rectangular. From the left, the reinforced curing mold I is located in the first T-shaped rib 9 and the second T Type II reinforcement curing mold is located between the third T type reinforcement 11 and the fourth T type reinforcement 12, and the No. III reinforcement curing mold is located between the fifth T type reinforcement 13 and Between the sixth T-shaped reinforcement 14, the IV reinforcement curing mold is located between the seventh T-shaped reinforcement 15 and the eighth T-shaped reinforcement 16, and the V reinforcement curing mold is located in the ninth T-shaped reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com