Method for eliminating bubbles of polyurethane (PU) injection moulding corner and obtained glass window

A glass window and bubble technology, applied in the coating and other directions, can solve the problems of high cost, long time consumption and ineffective effect of the exhaust groove, and achieve the effect of solving the bubble problem and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Present embodiment 1 is a three-bread type hemming process, and the specific steps are:

[0033] 1. Pretreatment: Clean the edge area of the glass plate 8, then apply the activator on the upper and lower surfaces and sides of the edge of the glass plate 8, leave it for 15 minutes, and then apply a primer on the area coated with the activator on the edge of the glass plate 8, Leave it for 30-240 minutes;

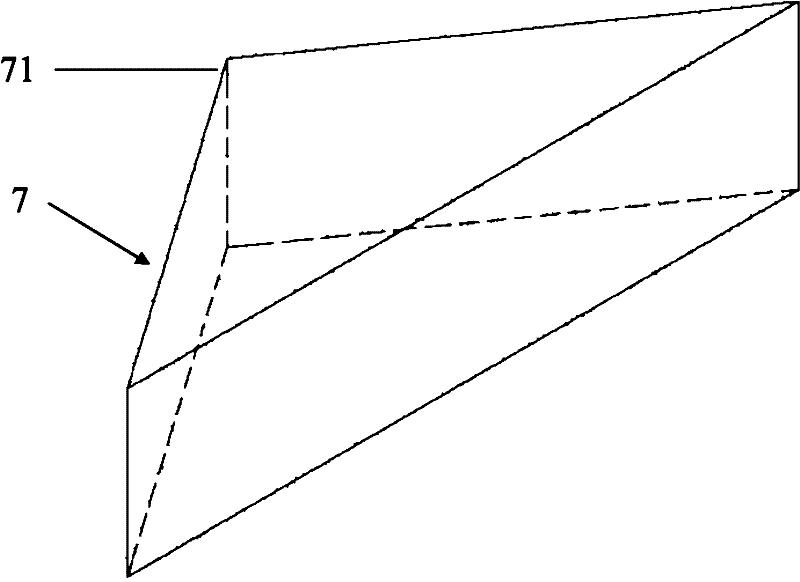

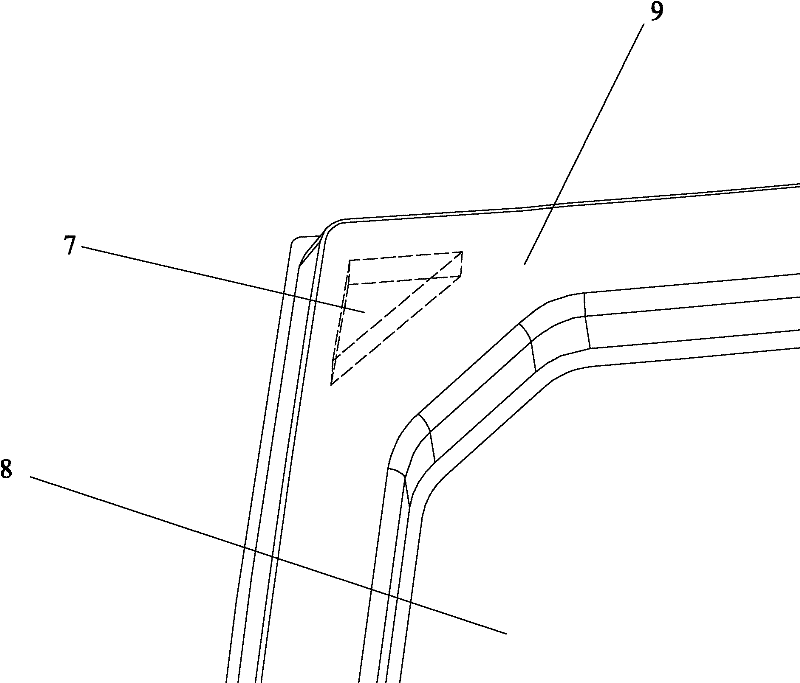

[0034] 2. Apply adhesive to the bottom surface of the insert 7, and then position and adhere the insert 7 to the corresponding position of the corner of the glass plate. The insert 7 is a three-dimensional triangular block, such as figure 1 As shown, its vertex 71 corresponds to the radian at the corner of the glass plate 8, the two sides of the vertex 71 are parallel to the two sides of the corner of the glass plate 8, and the distance between them is 2 mm, and the insert 7 also meets the following conditions : when the glass plate 8 edge portion and the insert 7 a...

Embodiment 2

[0040] Present embodiment 2 is the two-bread type hemming process, and the specific steps are:

[0041] 1. Pretreatment: Clean the edge area of the glass plate 8, then apply the activator on the side of the glass plate 8 edge and the other connecting surface, leave it for 15 minutes, and then apply the activator on the area coated with the activator on the edge of the glass plate 8 Primer, leave for 30-240 minutes;

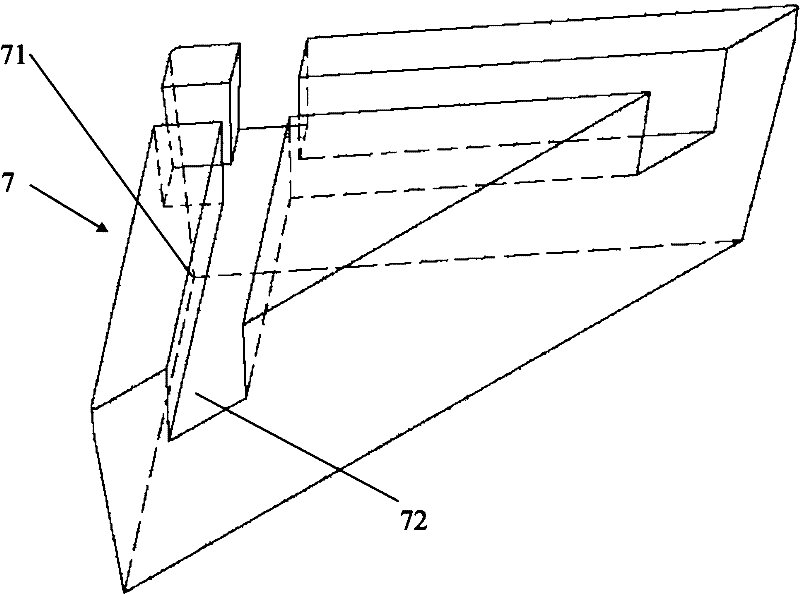

[0042] 2. Apply adhesive to the bottom surface of the insert 7, and then position and adhere the insert 7 to the corresponding position of the corner of the glass plate 8. The insert 7 is a three-dimensional triangular block, such as image 3 As shown, its vertex 71 corresponds to the radian at the corner of the glass plate 8, the two sides of the vertex 71 are parallel to the two sides of the corner of the glass plate 8, and the distance between them is 5 mm, and the insert 7 also meets the following conditions 1. There are two through grooves 72 that correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com