Turntable bearing in chassis articulated system of articulated vehicle

A technology of hinged system and slewing bearings, which is applied to the passageway for connecting vehicles, motor vehicles, vehicle parts, etc., can solve the problems of uneven setting, low reliability, complex structure, etc., and achieve compact structure and long service life , processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

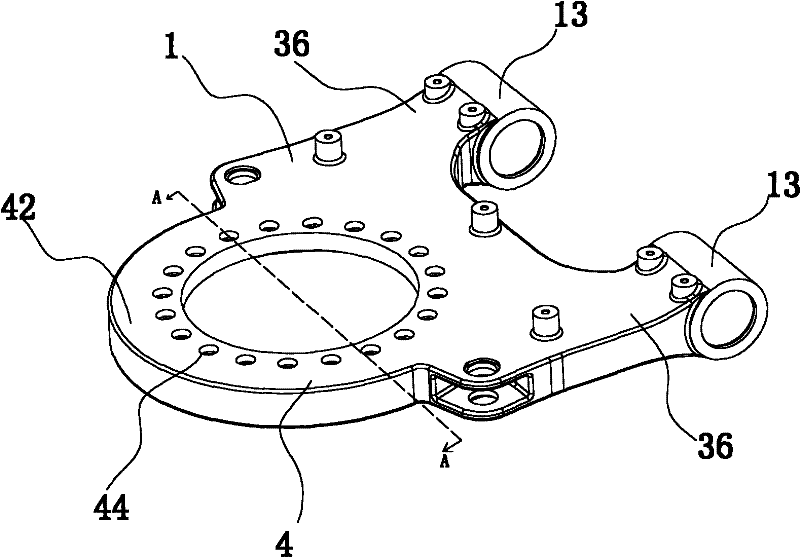

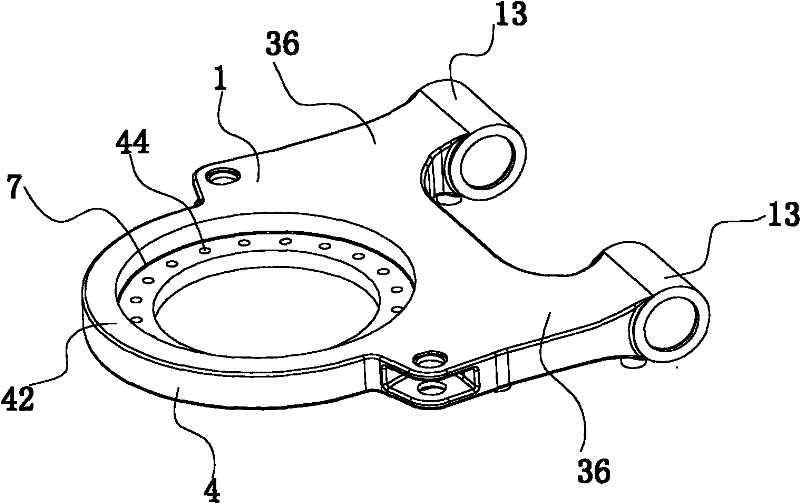

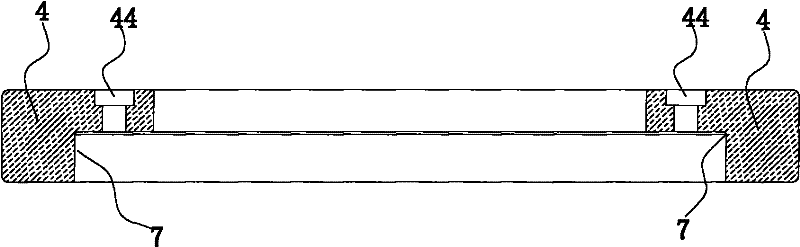

[0024] Such as Figure 1-Figure 9 As shown, the present invention relates to a turntable bearing in an articulated vehicle chassis hinge system, the chassis hinge system includes a front frame 1, a rear frame 2 and a turntable bearing 3, and the turntable bearing 3 includes an outer ring 4 and an inner ring 5, The outer ring 4 and the inner ring 5 can rotate with each other; the outer ring 4 is arranged on the outside of the inner ring 5 and arranged concentrically, and the inner ring 5 of the slewing bearing is fixedly connected with the rear frame 2 in the hinge system by screws. In the present invention, the outer ring 4 of the turntable bearing is integrated with the front frame 1, the rotation of the inner ring and the outer ring realizes the rotation of the front frame and the rear frame of the hinged system, and the front frame is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com