Modularized front panel of power distribution plug-in box

A front panel and plug-in box technology, which is applied to the components, circuits, and connections of the connecting device, can solve the impact of adding and expanding equipment function modules, messy and unreasonable division of internal space, and changeable connection methods of the plug-in box, etc. problem, to achieve the effect of good scalability, compact structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

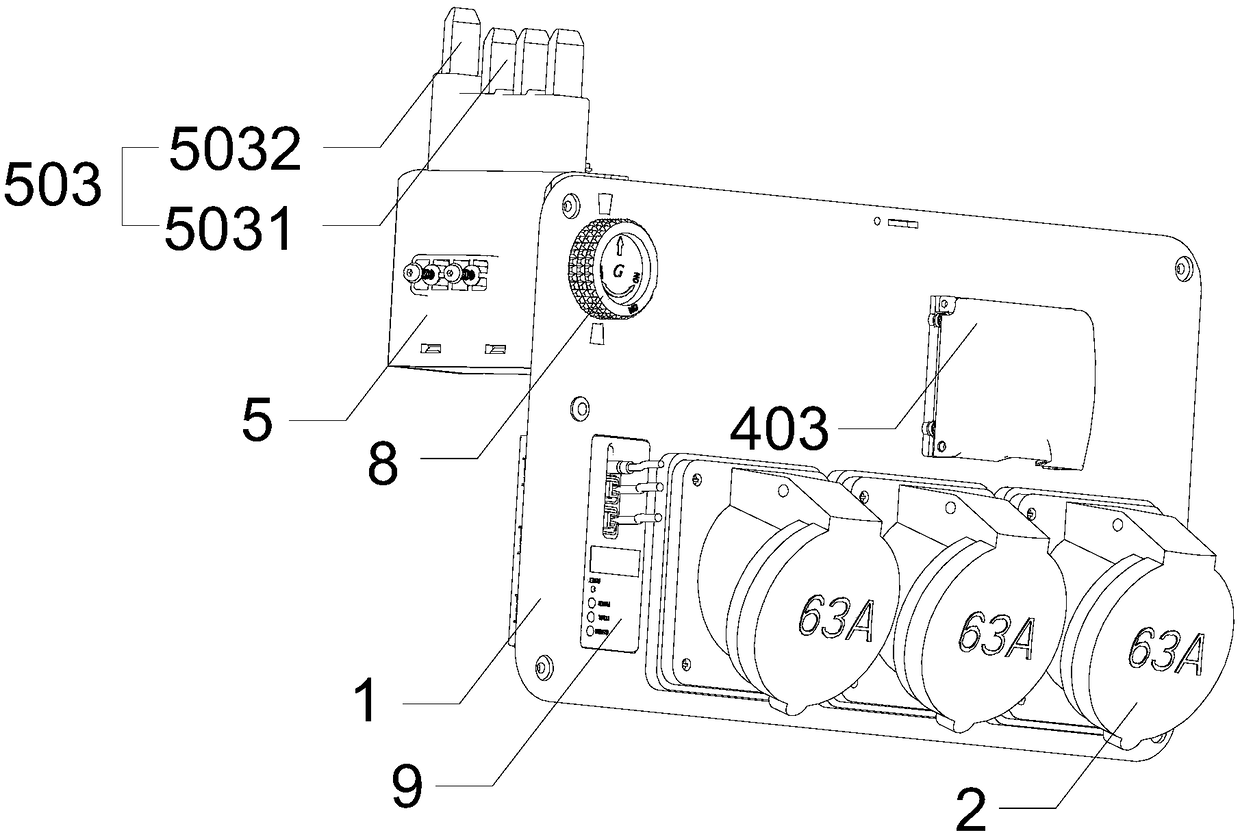

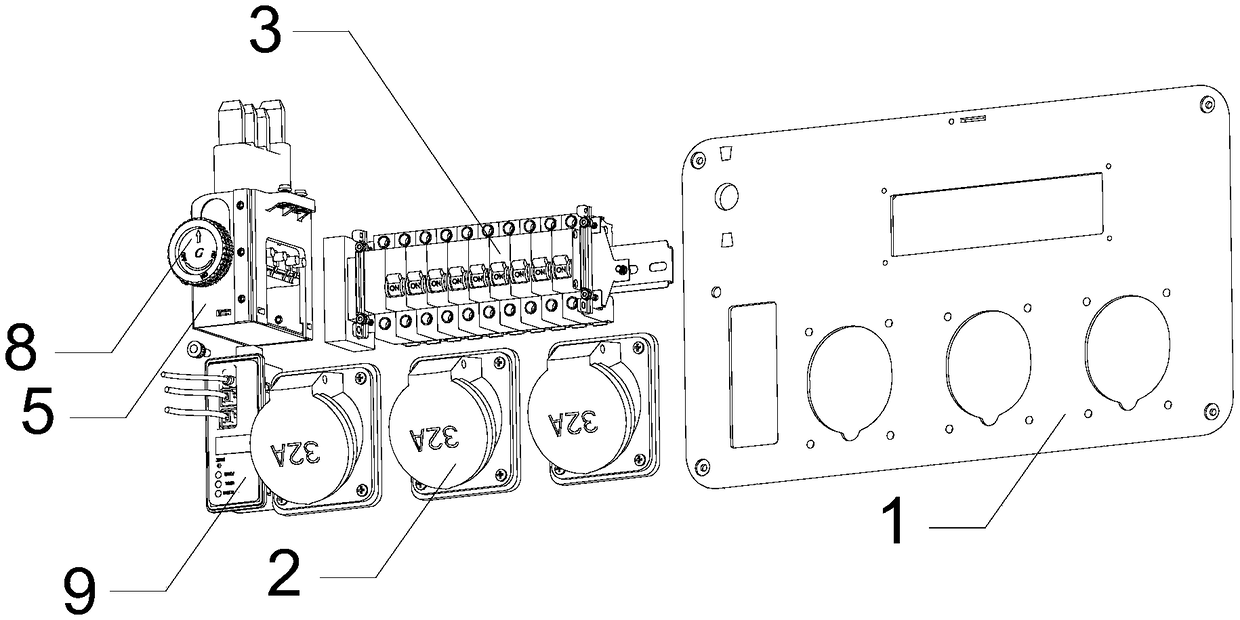

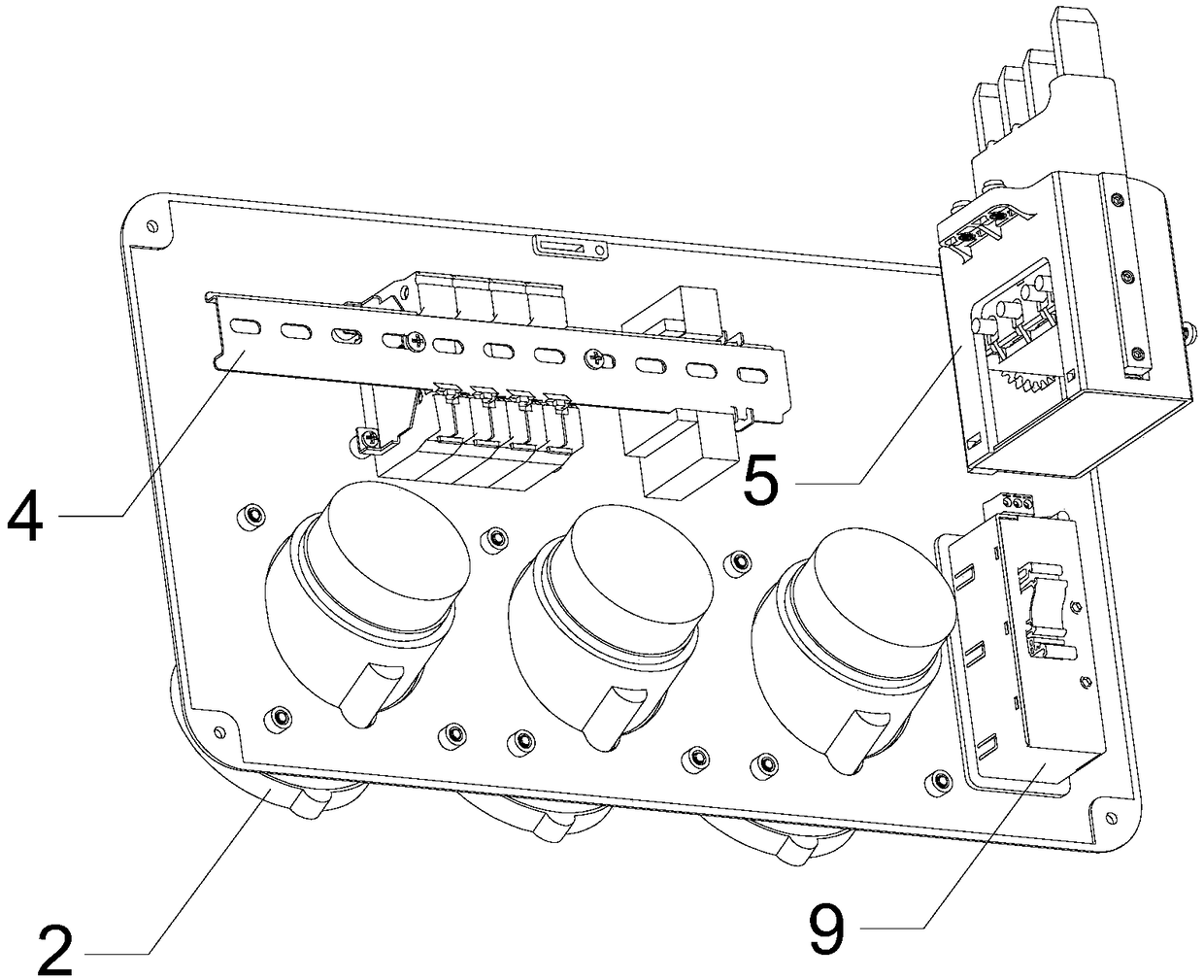

[0025] Such as Figure 1 to Figure 6 As shown, the present invention provides a modular front panel of a power distribution box, including a front panel 1, a power distribution coupler 2 is arranged on the front panel 1, and a miniature A circuit breaker 3, the miniature circuit breaker 3 is installed on the front panel 1 through a circuit breaker installation assembly 4, the number of the miniature circuit breaker 3 corresponds to the number of the power distribution coupler 2, the miniature circuit breaker One side of the device 3 is provided with a terminal drive mechanism 5, the terminal drive mechanism 5 controls the plug box to insert or pull out the bus duct, and the top of the terminal drive mechanism 5 is provided with a multi-function instrument 6, the multi-function instrument 6 Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com