Automobile clutch treadle mechanism

A technology for clutch pedals and pedals, which is applied to vehicle components, control devices, transportation and packaging, etc. It can solve problems such as flameout, damage to clutch plates, gearboxes, and incomplete clutching, etc., and achieve reliable performance and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

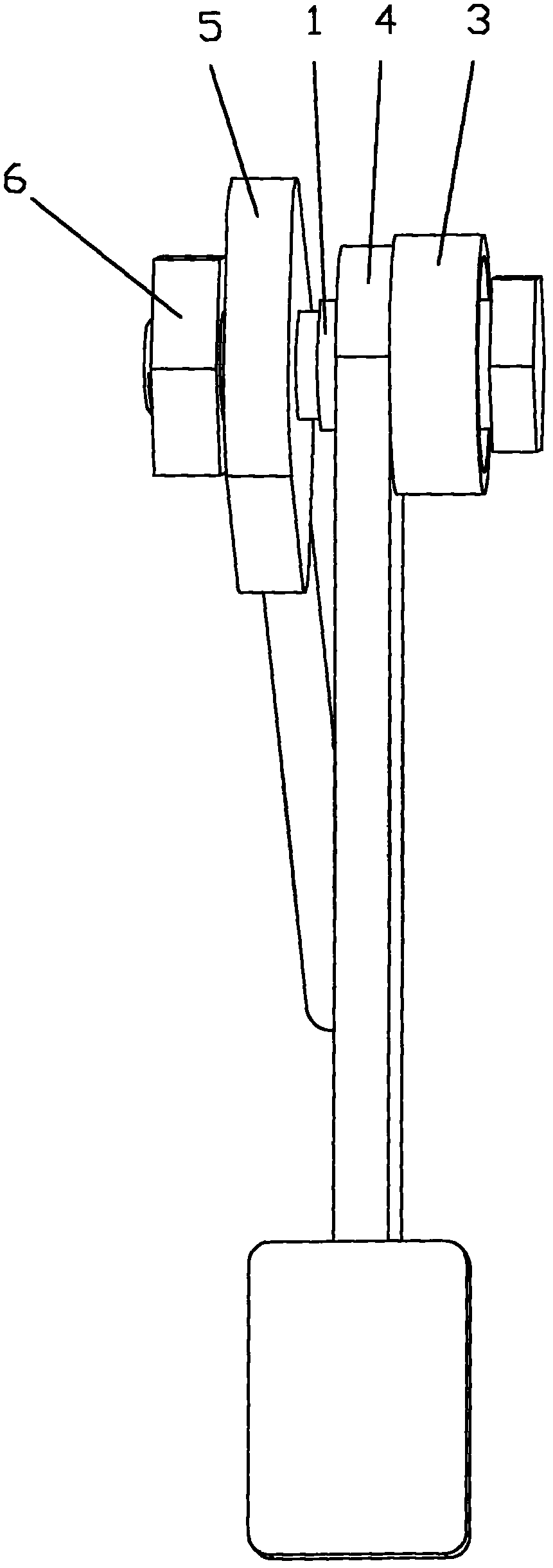

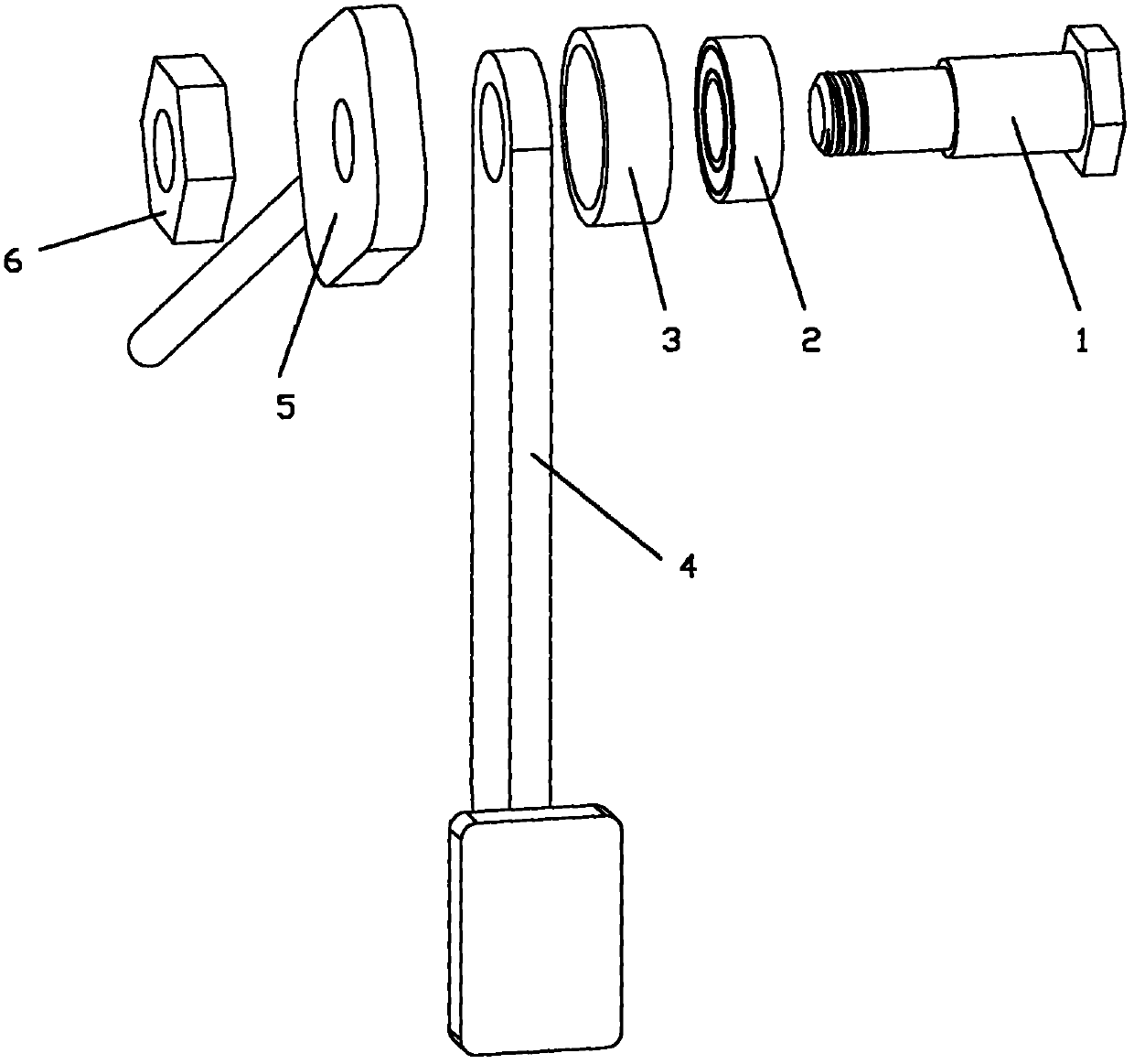

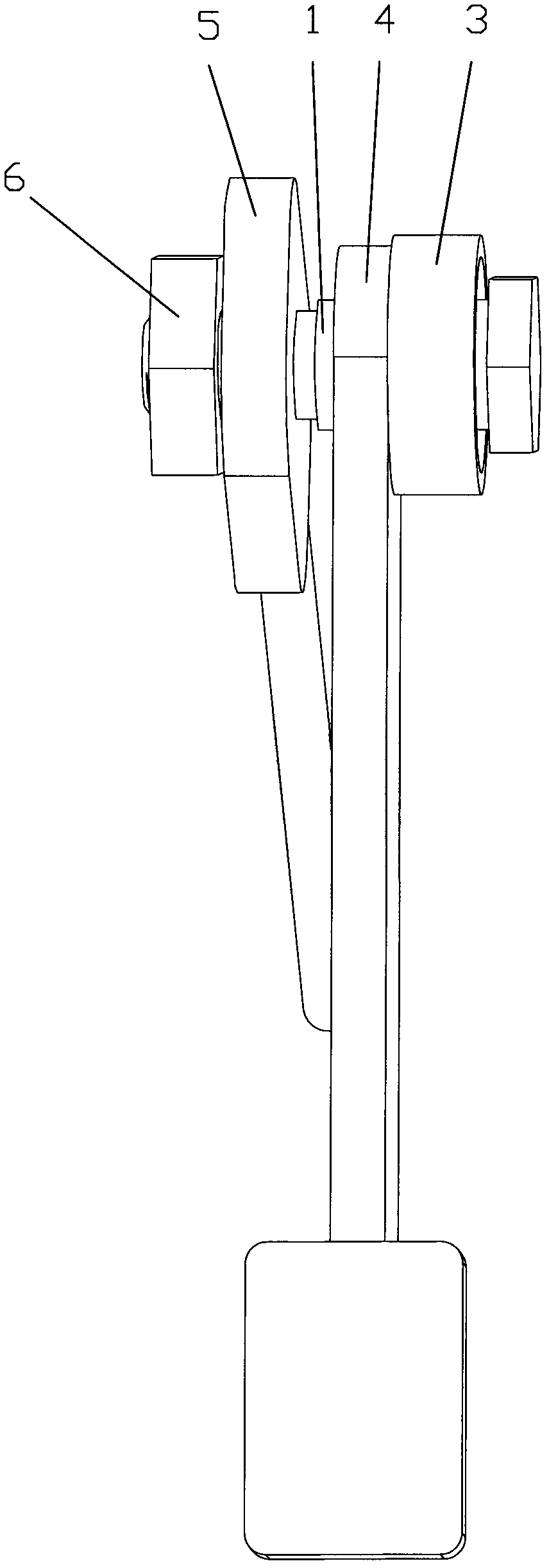

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but does not constitute any limitation to the present invention. figure 1 and figure 2 As shown, the present invention includes a pedal, a pedal handle 4, a hinge shaft 1 and an oil pump piston rod 5, the hinge shaft 1 is a stepped shaft, and a bearing 2 is set on the thick shaft of the hinge shaft 1, and the upper part of the pedal handle 4 and the outer ring of the bearing Welded as a whole, the oil pump piston rod 5 upper ends are contained on the thin shaft of the hinge shaft 1, and the hinge shaft 1 two ends are screwed with nuts 6. Under normal circumstances, the outer ring of the bearing is difficult to weld. In order to solve this problem, a snare 3 can be added to the outer ring of the bearing. The snare 3 and the outer ring of the bearing have an interference fit, and then the upper part of the pedal handle 4 and the snare 3 are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com