Steel-aluminum compound rail production line

A steel-aluminum composite and production line technology, applied in power lines, power rails, transportation and packaging, etc., can solve the problems of undisclosed steel-aluminum composite rail manufacturing technology and its dedicated production line, etc., and achieve a high degree of automation and high production speed. , compound solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below the present invention is further described in conjunction with the embodiment in the accompanying drawings:

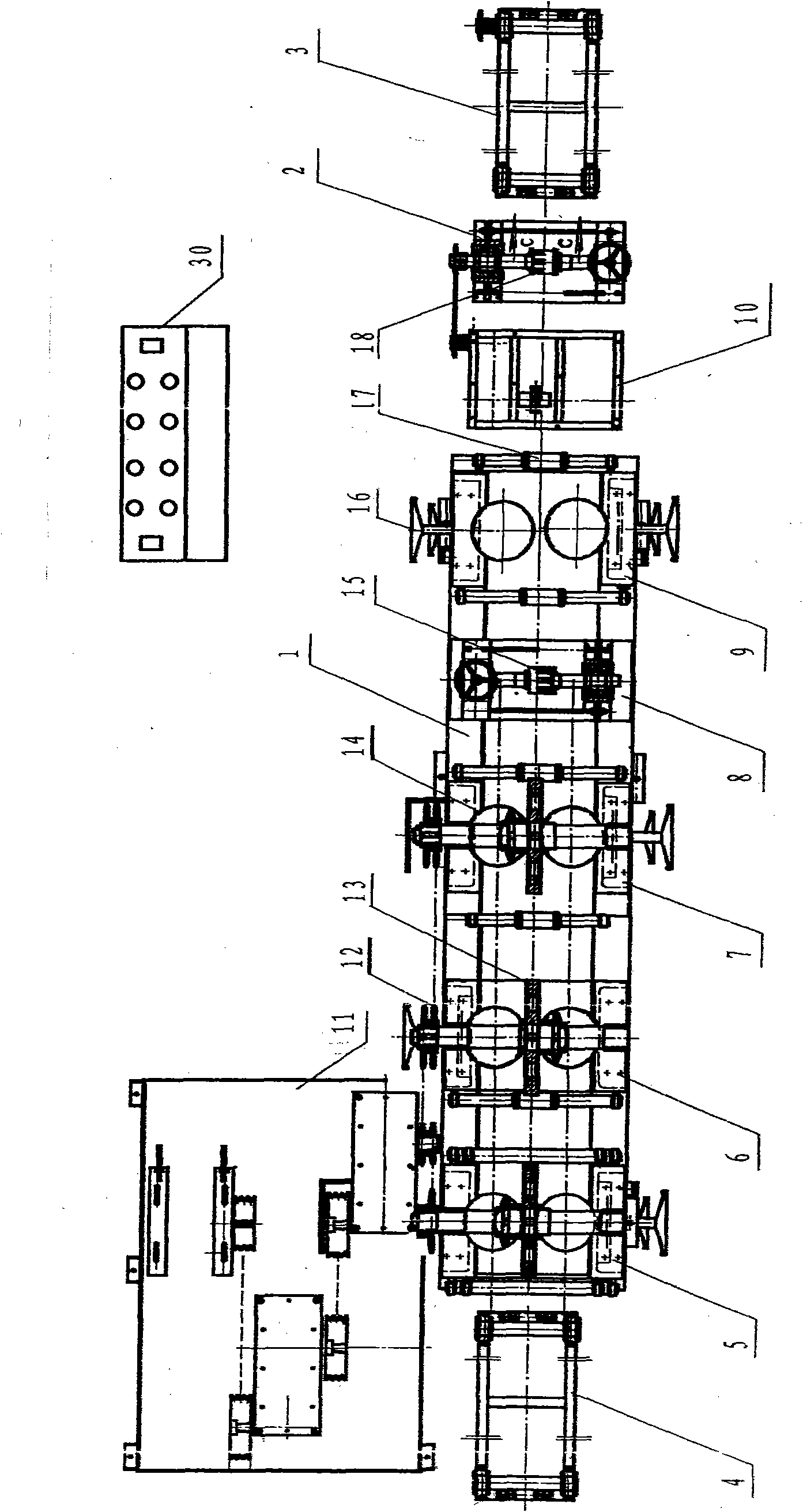

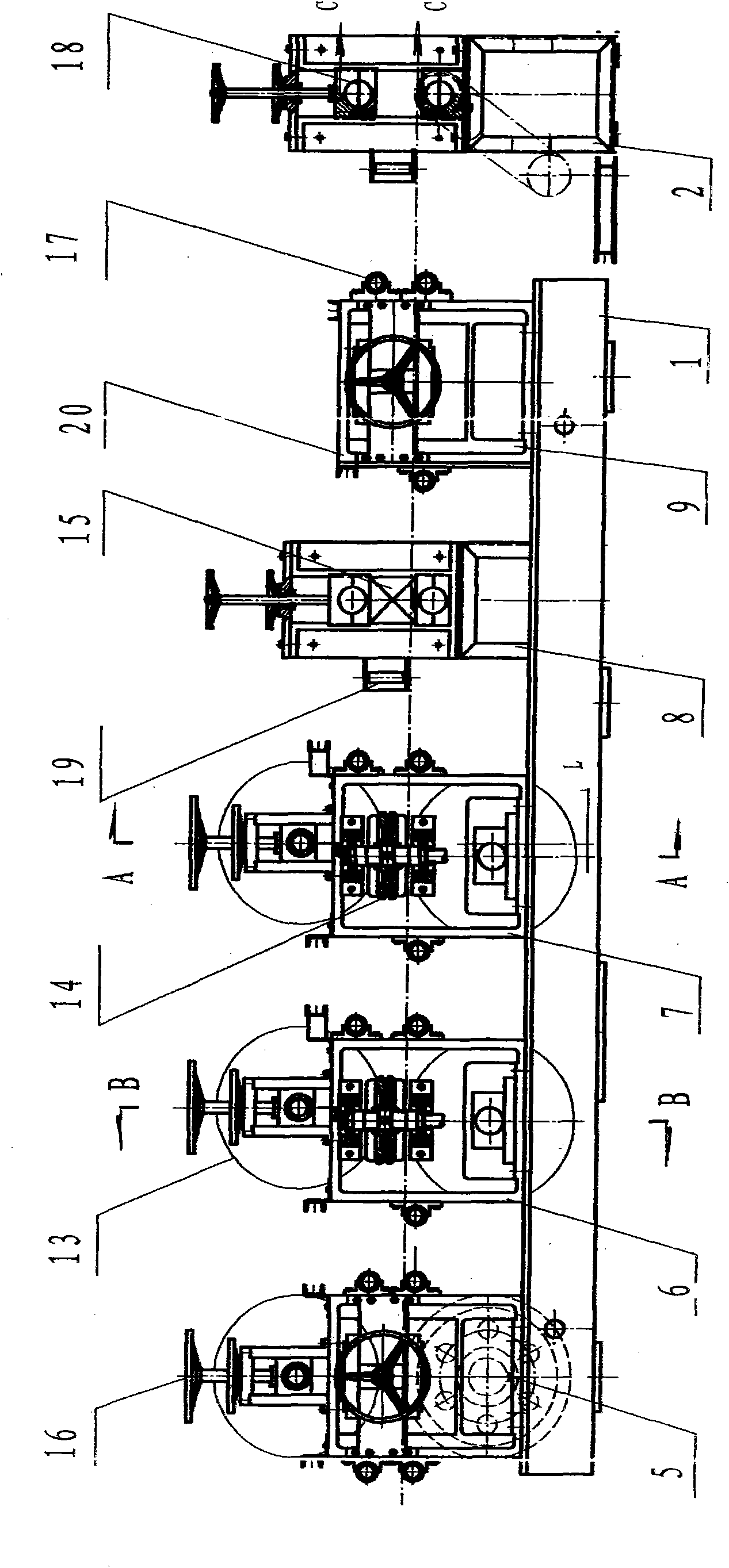

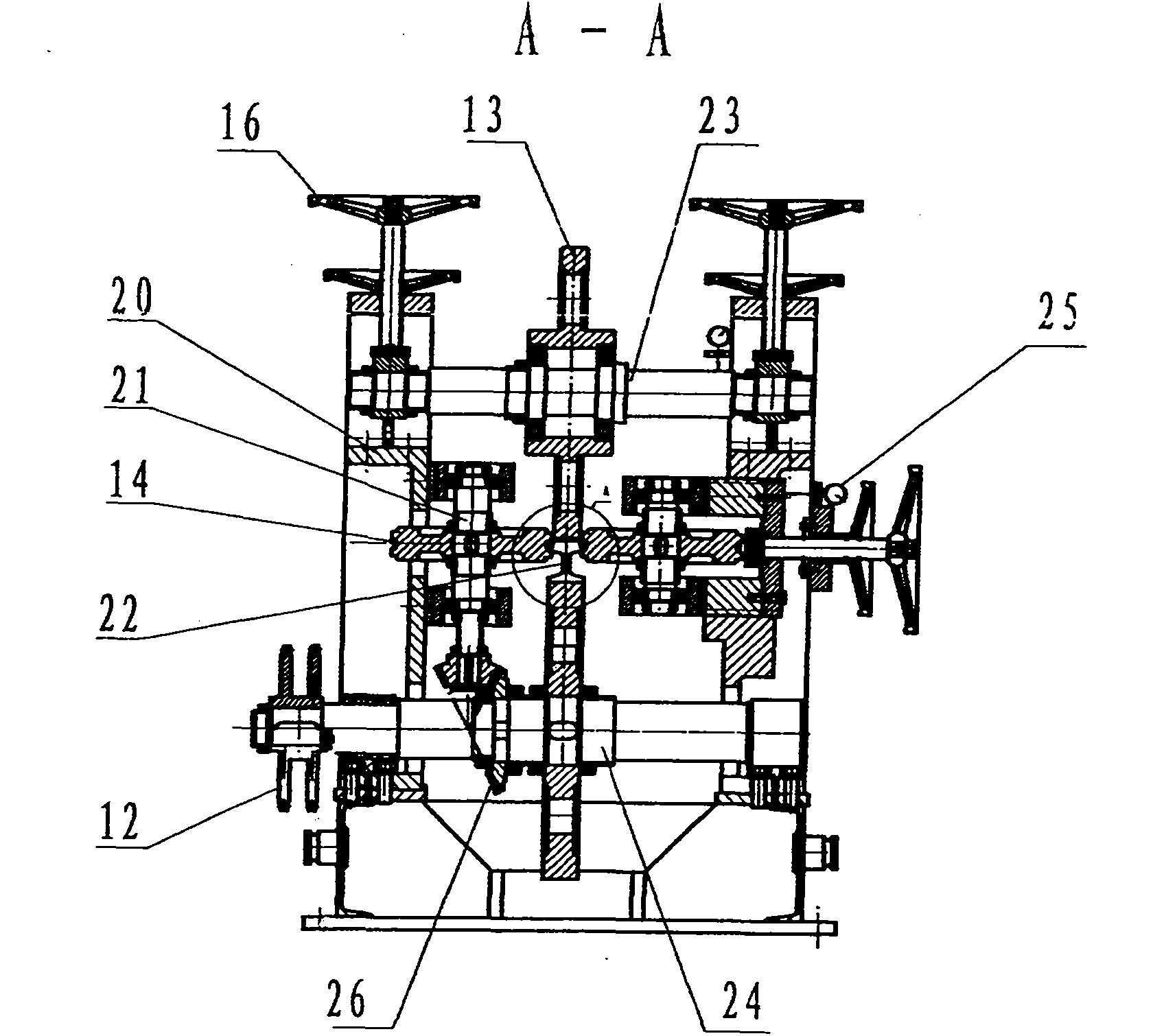

[0020] figure 1 It is an internal view of main equipment in the present invention. There is a feeding mechanism 4 on the left side of the main machine 1, and the shaping machine 2 and the traction machine 3 are arranged on the right side of the main machine 1 successively. The actual steel-aluminum composite rail production line has a tractor 3 and at least four conveying mechanisms 4 on both sides of the main machine respectively, so as to adapt to the length of the steel-aluminum composite rail and more than 15 meters. The conveying mechanism 4 has no power, and there are 2 guide rollers on the frame of each conveying mechanism. On the guide roller of the conveying mechanism 4 on the left side of the main machine 1, an uncomposited aluminum profile 27 is placed, and a stainless steel groove 29 is placed on it. . The feeding mechanism on the right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com