Automatic grouting monitoring equipment and method

An automatic monitoring and equipment technology, applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., can solve the problems of inconvenient, unable to automatically adjust the grouting pressure, and the working status of the sensor cannot be reflected in real time, so as to achieve the effect of convenient centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention is further described in detail below in conjunction with accompanying drawing:

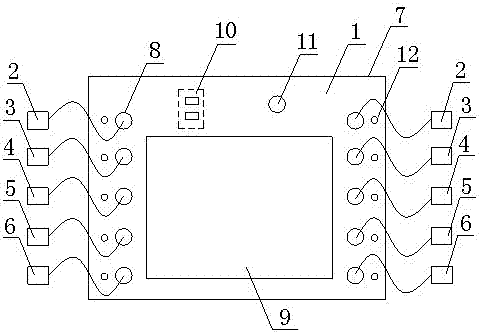

[0022] Such as figure 1 As shown, the automatic grouting monitoring equipment includes a grouting collector 1 and a sensor group connected to the grouting collector 1, and the sensor group includes a grouting sensor 2, a grouting sensor 3, a pressure sensor 4, a density sensor 5 and deformation Sensor 6; Described grouting collection instrument 1 comprises casing 7 and is arranged on the control circuit inside casing 7; The casing 7 is provided with sensor socket group 8, touch screen 9, two USB interfaces 10 and alarm interface 11, Each socket in the sensor socket group 8 is provided with a corresponding indicator light 12, and the sensor working state indicator light 12 reflects the working state of each sensor in real time.

[0023] The automatic grouting monitoring device of the present invention replaces the traditional liquid crystal disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com