Multi-station full automatic laser power measuring method and system

A technology of laser power and test system, applied in the field of communication, can solve the problems of low efficiency, difficult to find faults in time, easy to affect physical health, etc., so as to reduce the probability of radiation exposure and improve the test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

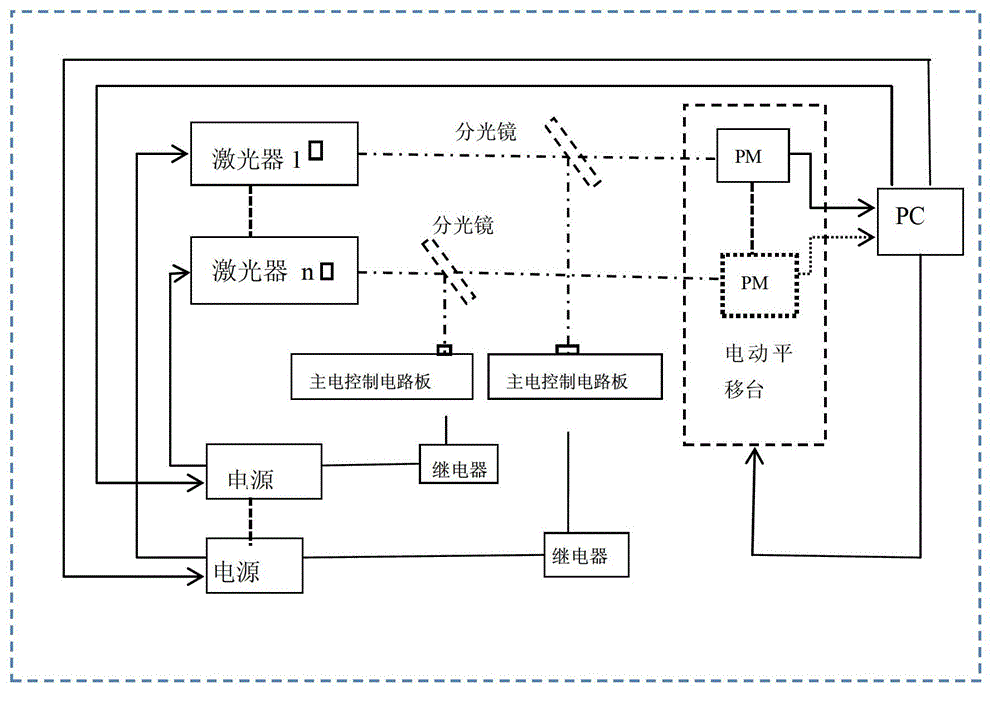

[0036] The embodiment of the present invention provides a multi-station fully automatic laser power testing method, which uses a multi-station fully automatic laser power testing system, see figure 1 , the system includes: one or more lasers, a main electric control circuit board corresponding to the lasers one by one, a beam splitter and a relay;

[0037] The main electric control circuit board receives the laser light of the laser reflected by the corresponding spectroscope, and analyzes and judges the reflected laser light. When it is determined that the reflected laser light is abnormal, the relay will Control the laser power off.

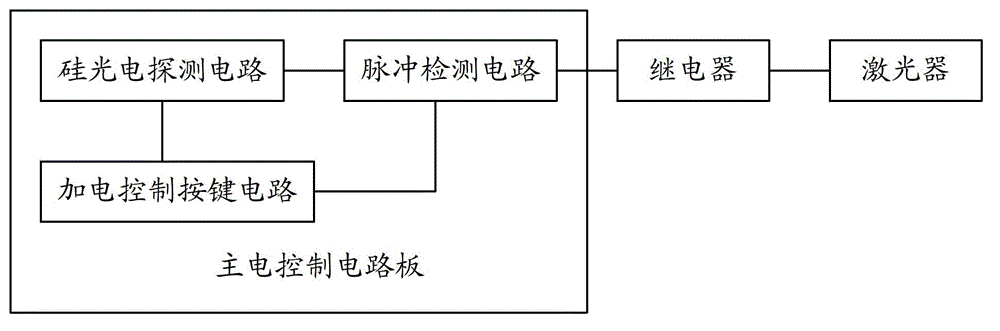

[0038] Wherein, the main electric control circuit board includes: a silicon photoelectric detection circuit and a pulse detection circuit, see figure 2 ;

[0039] The silicon photoelectric detection circuit converts the optical signal of the laser light reflected by the beam splitter into an electrical signal, and sends it to the pulse detec...

Embodiment 2

[0049] The embodiment of the present invention provides a multi-station automatic laser power testing system, see figure 1 , the system includes: one or more lasers, a main electric control circuit board corresponding to the lasers one by one, a beam splitter and a relay;

[0050] The laser is used to emit a laser beam;

[0051] The main electric control circuit board is used to receive the laser light of the laser reflected by the corresponding beam splitter, analyze and judge the laser light, and trigger the relay when it is determined that the laser light is abnormal;

[0052] The relay is used to turn off the power of the laser.

[0053] Preferably, the main electric control circuit board includes: a silicon photodetection circuit and a pulse detection circuit, see figure 2 ;

[0054] The silicon photoelectric detection circuit is used to convert the optical signal of the laser light reflected by the beam splitter into an electrical signal, and send it to the pulse det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com