Conical nut assembly for creeping formwork construction and installation method

A tapered nut and nut technology, which is applied to the connection parts of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of high cost of disassembling wrenches for easily damaged nuts, plastic nut sleeves, stickiness, etc. Large relay force and other problems, to achieve the effect of easy disassembly of fixing bolts, simple structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

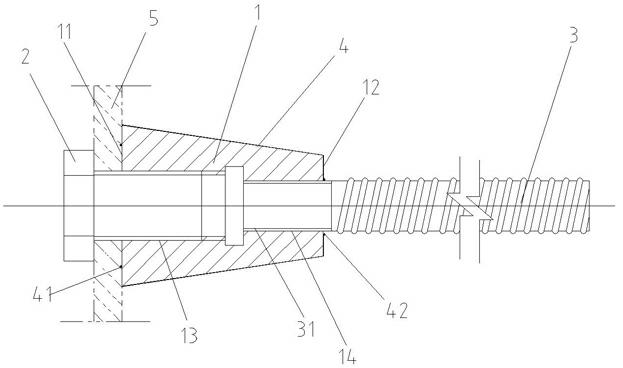

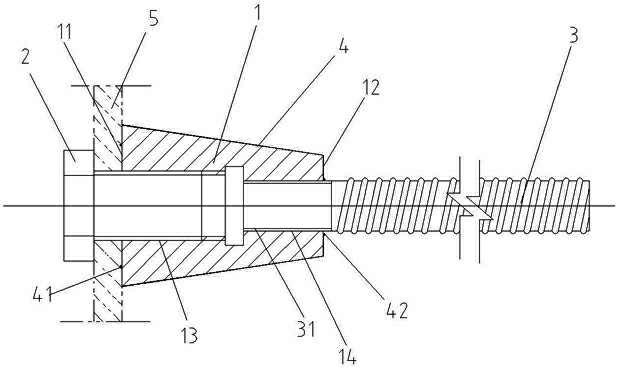

[0016] Such as figure 1 Shown, the tapered nut combination of the present invention comprises tapered nut 1, the fixed bolt 2 that is fixedly connected with tapered nut 1 large end, the tail muscle 3 that one end is fixedly connected with tapered nut small end, wrapping tapered nut 1 Nut rubber cover 4, the taper nut 1 two ends of the present embodiment have different threaded holes, and the taper nut 1 two ends are respectively fixedly connected with different diameters, different pitches of fixing bolts 2, tail ribs 3 threaded ends 31. Screw the tail tendon 3 into the tapered nut 1 from the small end plane 12 of the tapered nut, and screw the fixing bolt 2 into the tapered nut 1 from the big end plane 11 of the tapered nut, so that the tail tendon 3, the tapered nut 1 and the fixing bolt 2 are connected into a combination of embedded nuts that can jointly bear the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com