Rigid transmission chain

A transmission chain and rigid technology, applied in the field of basic component chains, can solve problems such as inability to realize rigid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

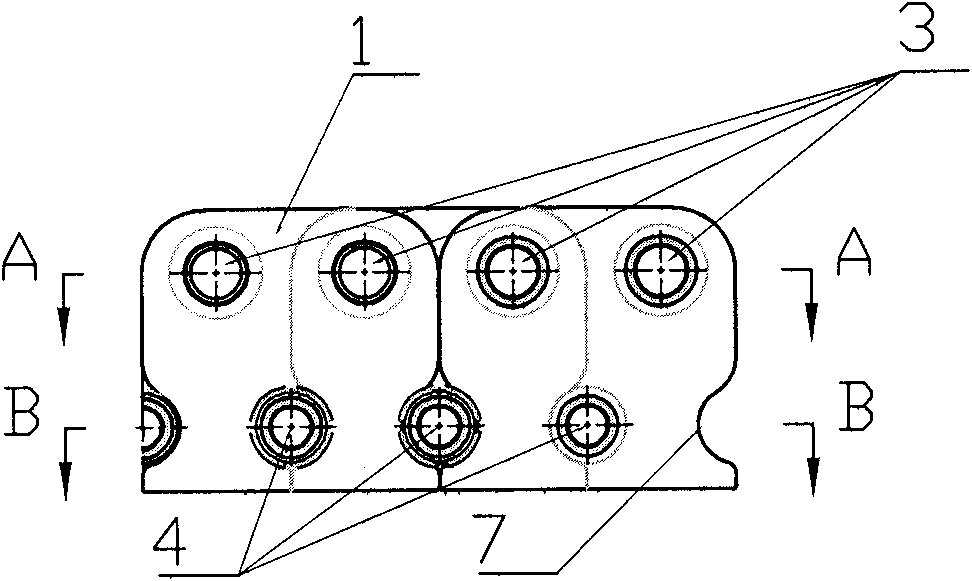

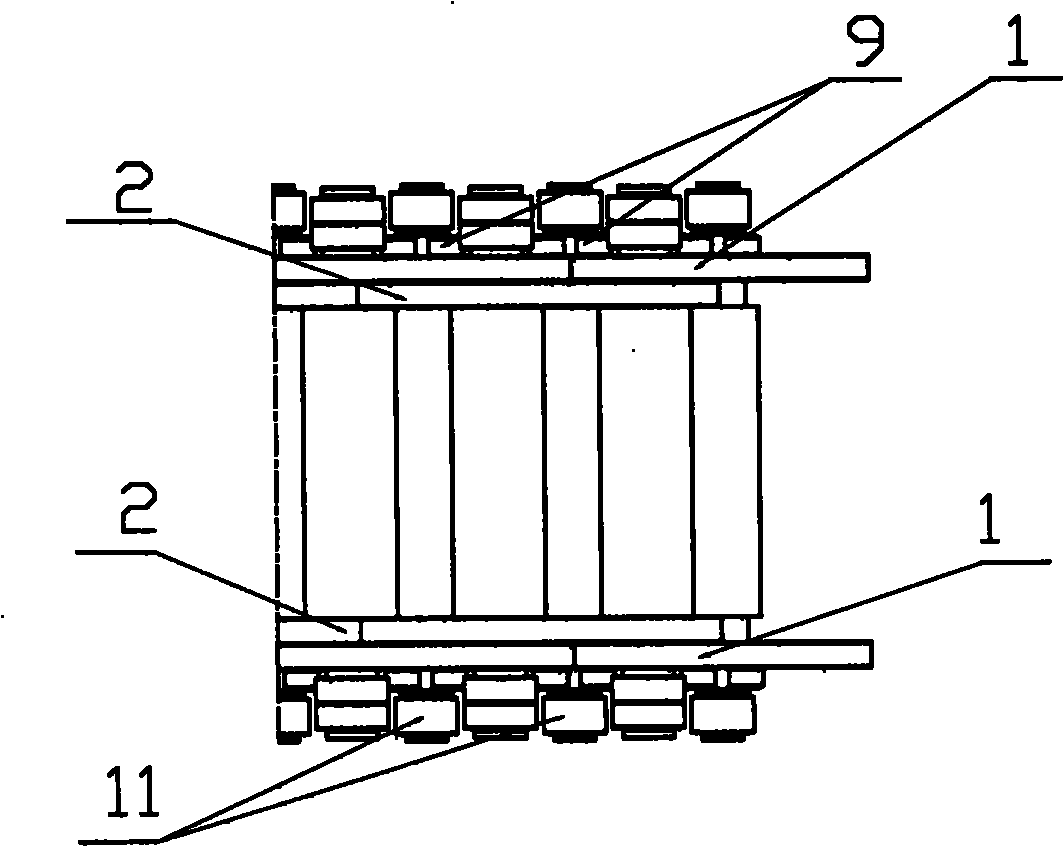

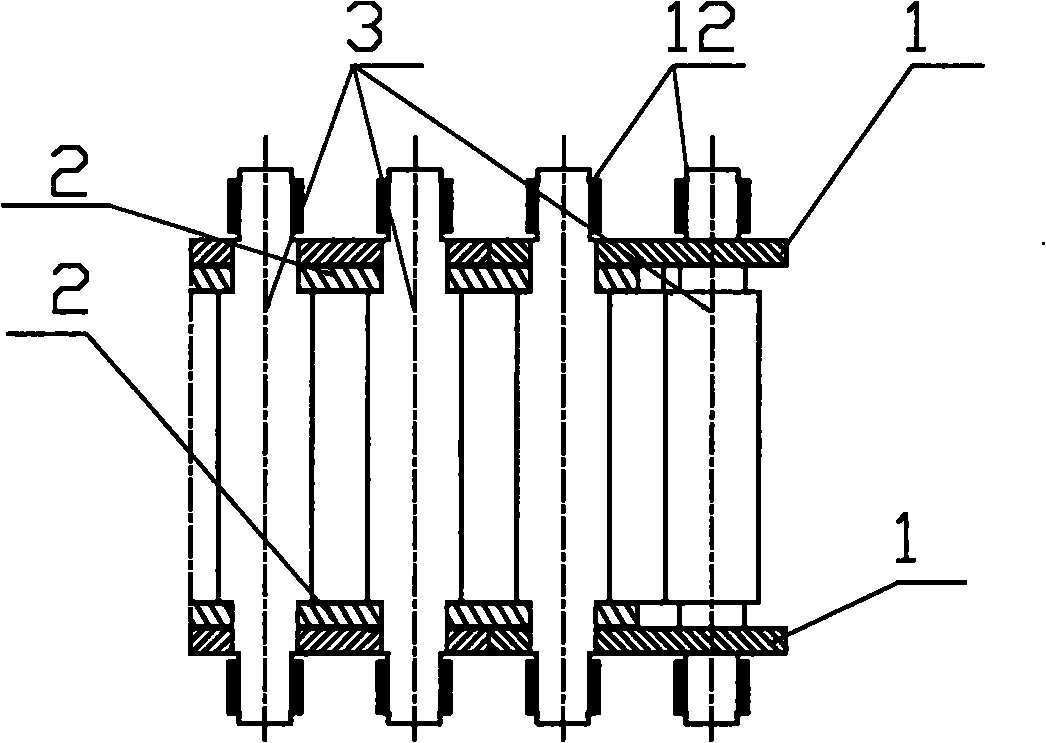

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the rigid transmission chain of the present invention includes multiple pairs of outer connecting plates 1, multiple pairs of inner connecting plates 2 arranged on the inner side of the outer connecting plates 1, and also includes a plurality of upper connecting shafts 3 and lower connecting shafts 4; The upper edge of the outer connecting plate 1 and the inner connecting plate 2 are symmetrically provided with the same rounded corners on both sides, the lower edge is straight and parallel to the upper edge, and the left and right edges are perpendicular to the lower edge. The outer connecting plate 1 and the inner connecting plate The upper end of the plate 2 is symmetrically provided with a left upper shaft hole 5 and a right upper shaft hole 6 with the same diameter, two semicircular holes 7 are symmetrically arranged on both sides of the lower end, and a lower shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com