Elliptical polarization instrument sample room device with variable temperature and temperature change method thereof

A technology of ellipsometer and sample chamber, which is applied in the direction of using electric temperature control, auxiliary controller with auxiliary heating device, and testing optical properties, etc. It can solve the problems of complicated sample stage manufacturing process and few users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

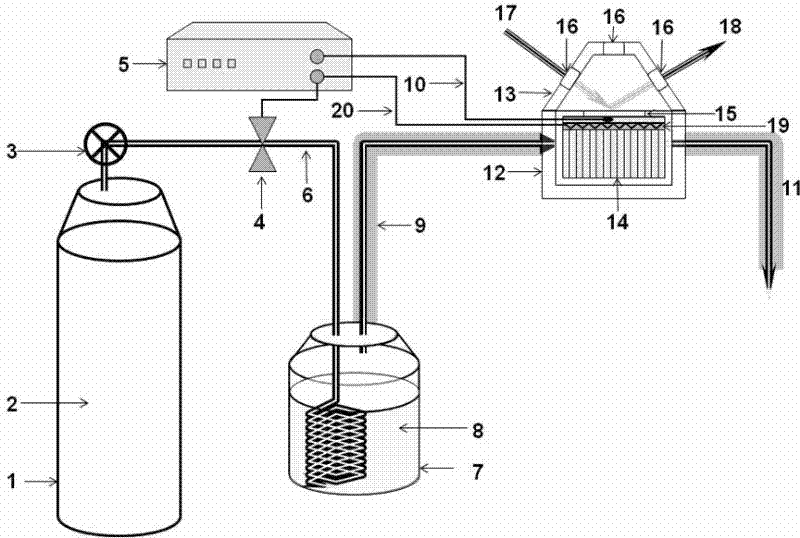

[0019] Such as figure 1 As shown, the device includes gas cylinders, gas valves, solenoid valves, Dewar bottles, sample chambers, sample stages, heating resistors, thermal resistors Pt100, temperature controllers and other parts. The steel cylinder 1 is used to load the working gas. In this example, the working gas is nitrogen gas 2 at room temperature. Use a plastic air pipe to draw nitrogen out of the steel cylinder through a manual air valve 3, and then connect it to a thin copper tube 6 through a solenoid valve 4. The thin copper tube passes through the rubber stopper of the Dewar bottle and enters the Dewar bottle 7. One end in the Dewar is in the shape of a helix. Fill the Dewar bottle with refrigerated liquid nitrogen 8. When working, the nitrogen gas output from the spiral thin copper tube will heat the liquid nitrogen, so that part of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com