Platform for testing performance of main shaft of machine tool

A machine tool spindle and testing platform technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve problems such as inability to fully test the technical performance of the spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

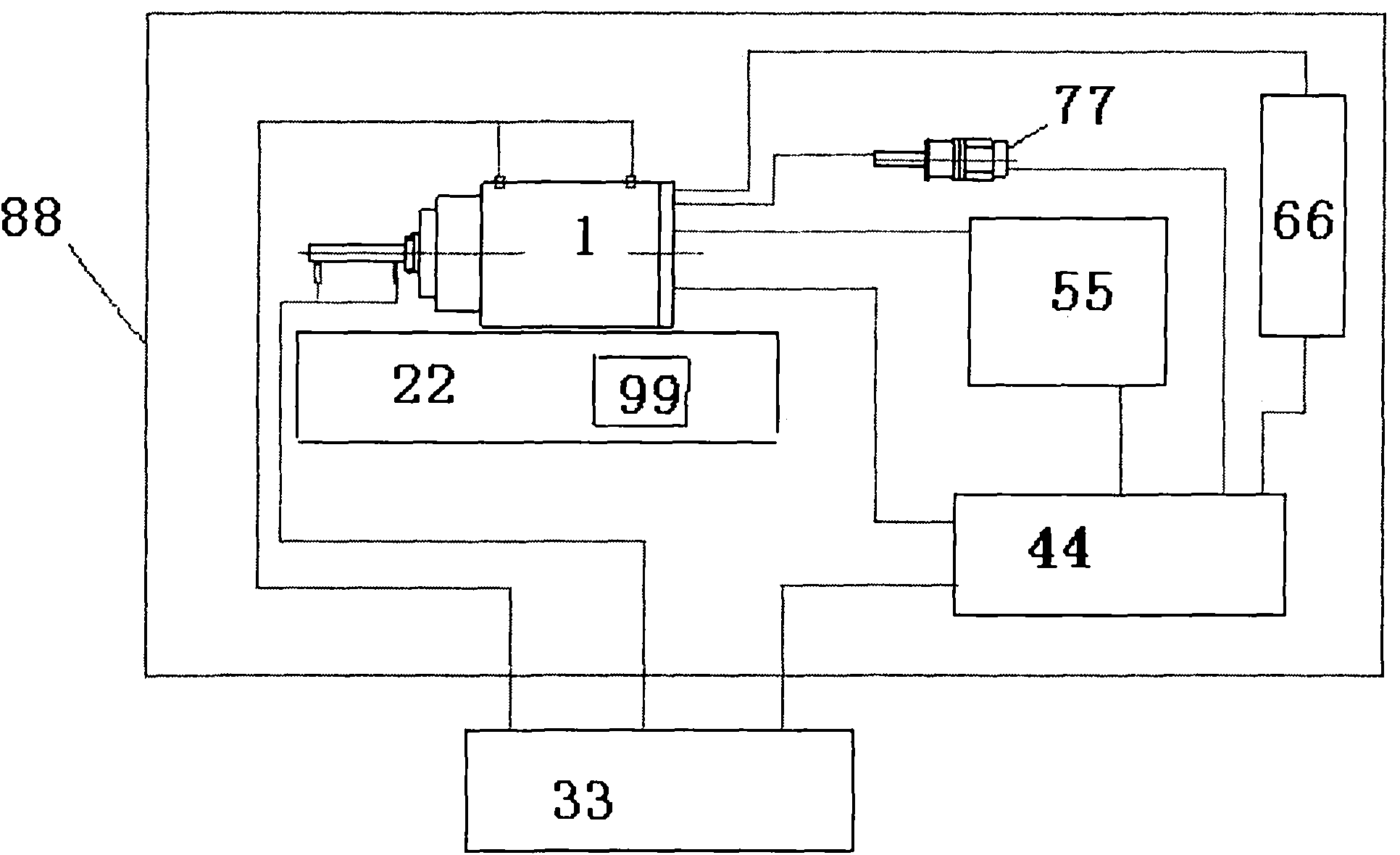

[0020] Such as figure 1 Shown is the principle diagram of the machine tool spindle performance testing platform of the present invention. The machine tool spindle performance test platform of the present invention includes the following units: a spindle unit 1, a test bench 22, an operating table 33, a numerical control system 44, a hydraulic station 55, a constant temperature oil tank 66, an air source 77, a protection net 88 and a test device 99. The base of the test bench 22 is welded with square steel, and the top is welded with the integral steel plate to form the foundation of the test bench 22. Various test devices 99 are installed on the top of the test bench 22, including a spindle thermal deformation detection device and a dynamic precision detection device. The spindle unit 1 is fixed on the test bench 22 by two sets of clamping devices. The front end of the spindle unit 1 is provided with a test device 99 for testing the technical performance of the spindle.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com