Capacity monitoring method of robot spot-welding production line

A robot welding and robot technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low rhythm of robot spot welding workstation, production impact of welding production line, and can not be reflected in time, so as to achieve reasonable and timely The effect of production planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

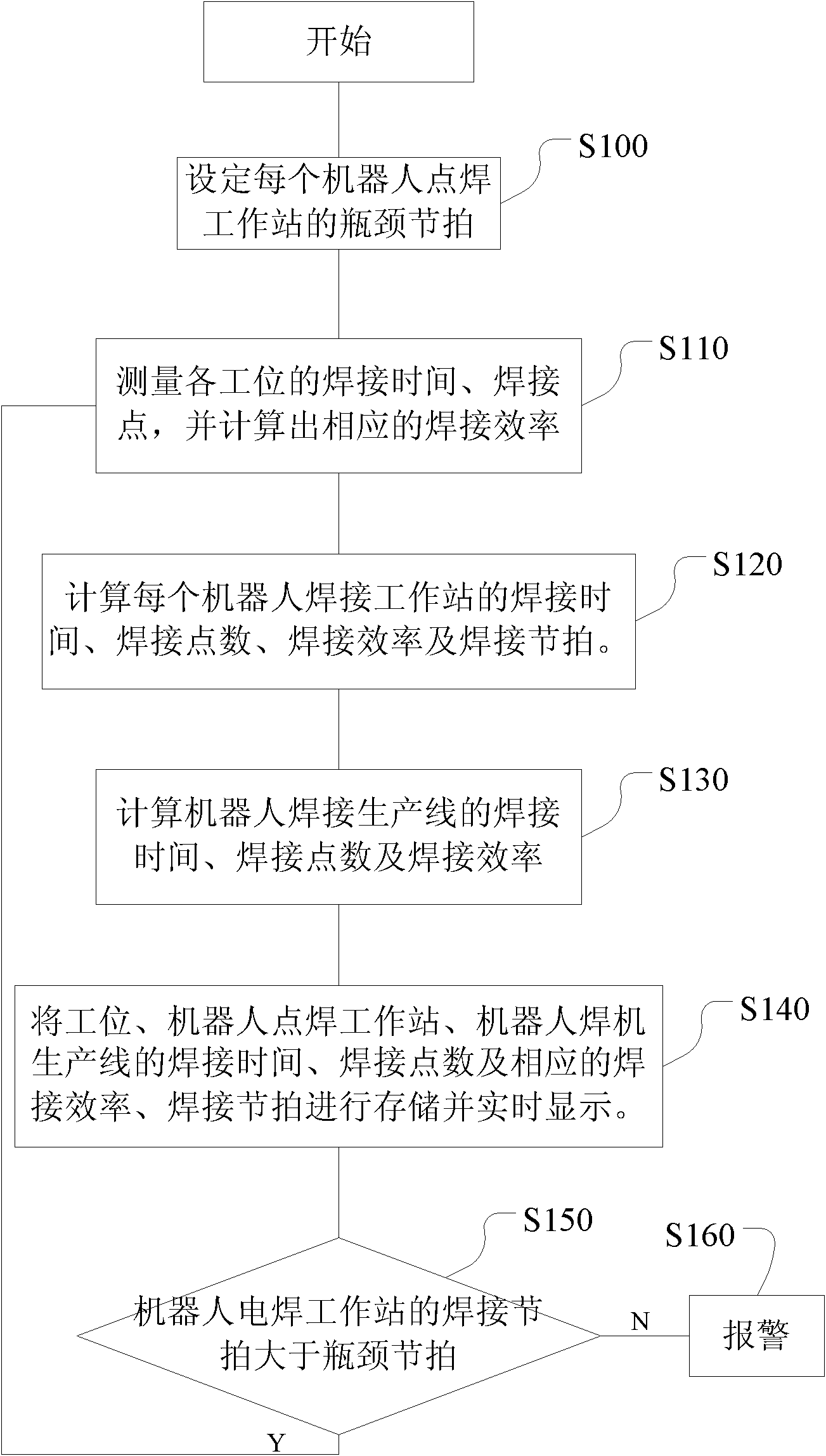

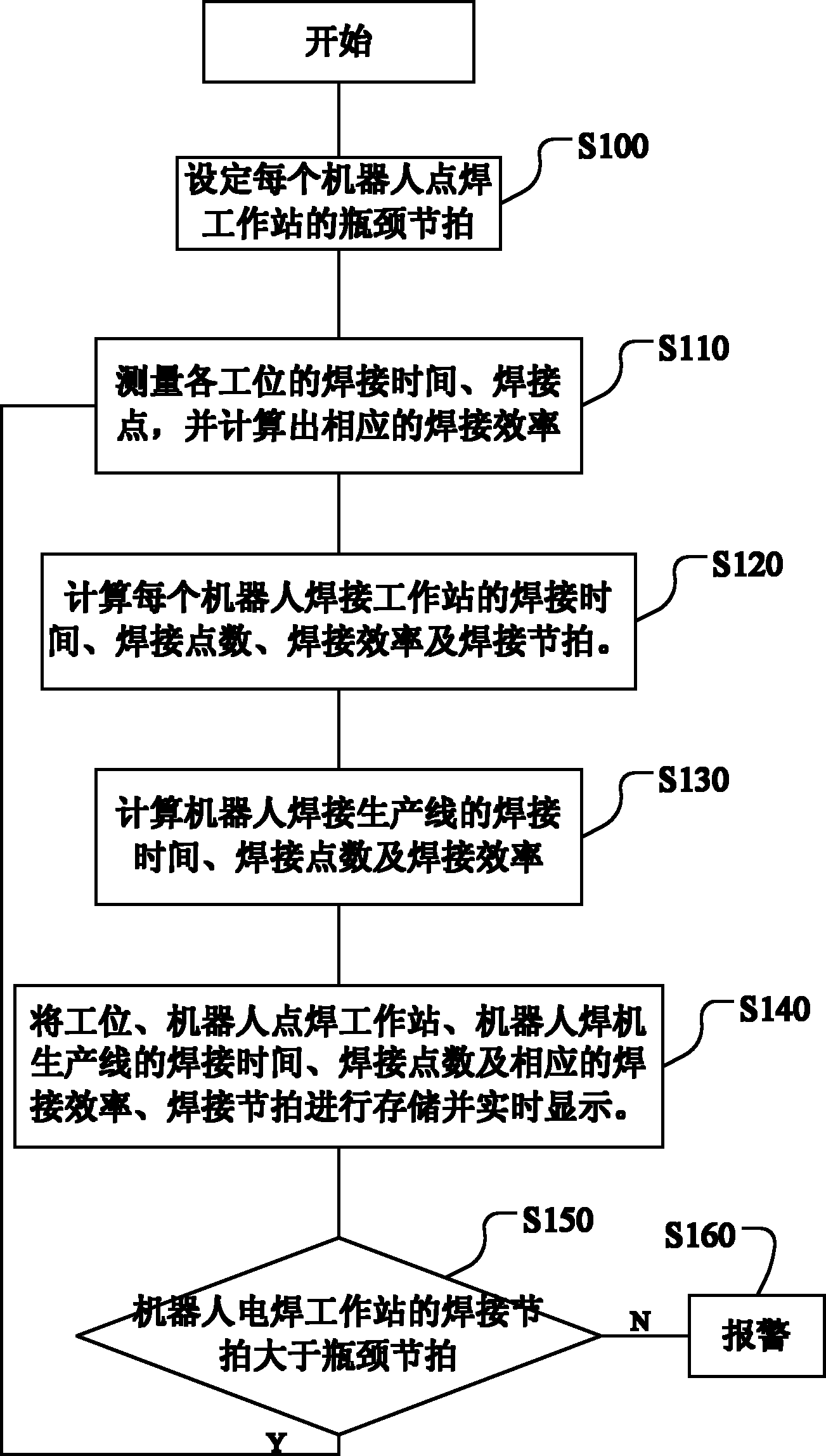

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The robot spot welding production line includes multiple robot spot welding workstations, each robot spot welding workstation includes multiple stations, and the spot welding robot of the same robot spot welding workstation can only weld the workpiece on one station at the same time. Such as figure 1 As shown, when the production capacity monitoring method of the robot spot welding production line is in operation, step S100 is first performed to set the bottleneck beat of each robot spot welding workstation. The bottleneck beat setting should be set according to the requirements of the production capacity plan. The bottleneck beat It should be the minimum takt that can complete the requirements of the capacity plan.

[0019] Then execute step S110, measure the welding time and the number of welding points of the spot welding robot at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com