Light-emitting diode packaging structure

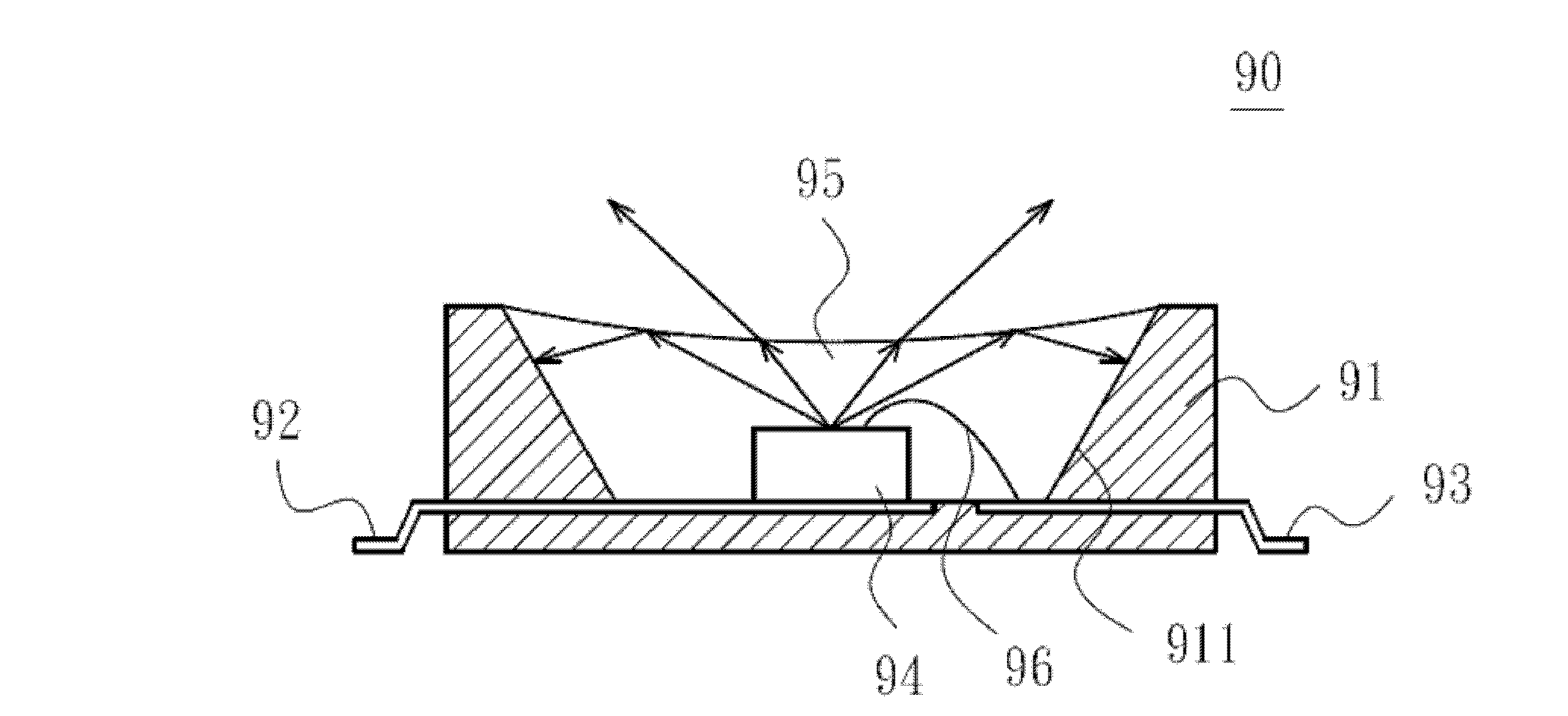

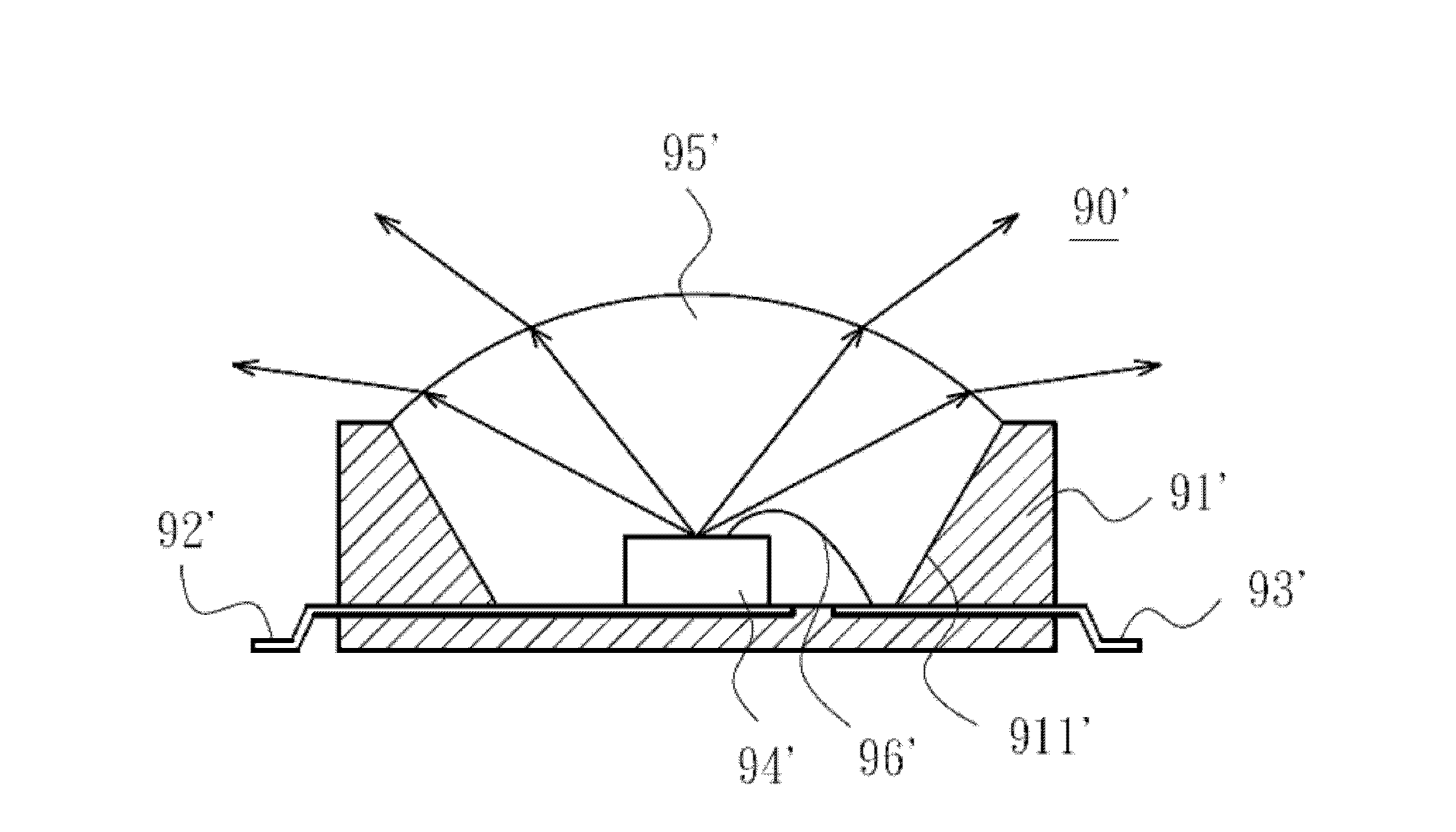

A technology for light-emitting diodes and structures, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as increasing the production cost of the light-transmitting packaging portion 95', unfavorable for light-emitting diode packaging structures SMT or other manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

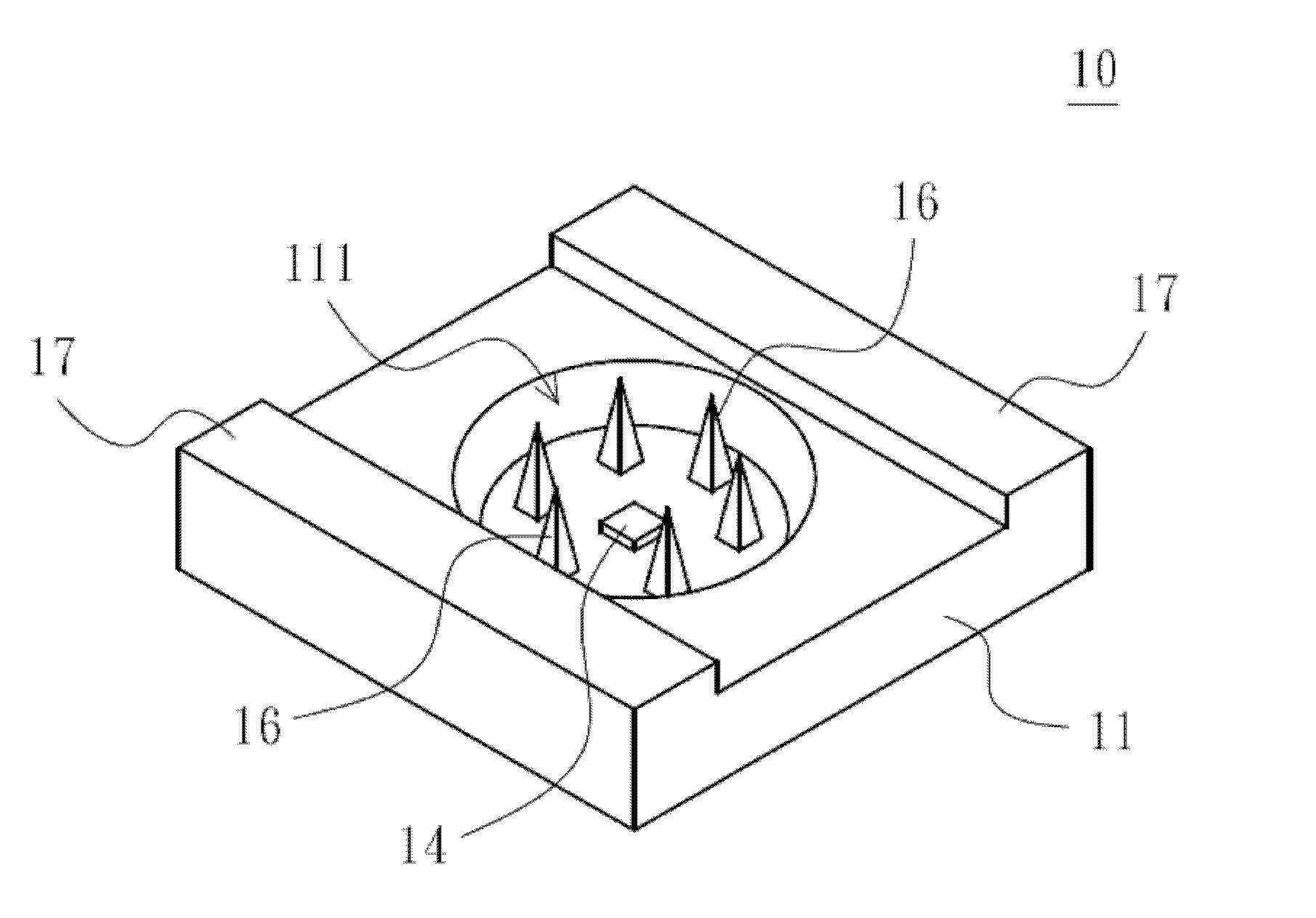

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below together with the accompanying drawings. Wherein, in order to show the main part of the LED package structure more clearly, the three-dimensional schematic diagrams in the accompanying drawings of the present invention show the main features in a simplified manner.

[0037] Please also refer to Figure 3A and Figure 3B , Figure 3A A three-dimensional schematic diagram of the housing and the LED chip of the first embodiment of the LED packaging structure of the present invention; Figure 3B It is a cross-sectional view of the first embodiment of the light emitting diode packaging structure of the present invention. The LED packaging structure 10 includes: a casing 11 , a first electrode sheet 12 , a second electrode sheet 13 , an LED chip 14 and a light-transmitting packaging portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com