Detection system for power tool

一种动力工具、检测系统的技术,应用在动力工具领域,能够解决难以区分状态缓解机制等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

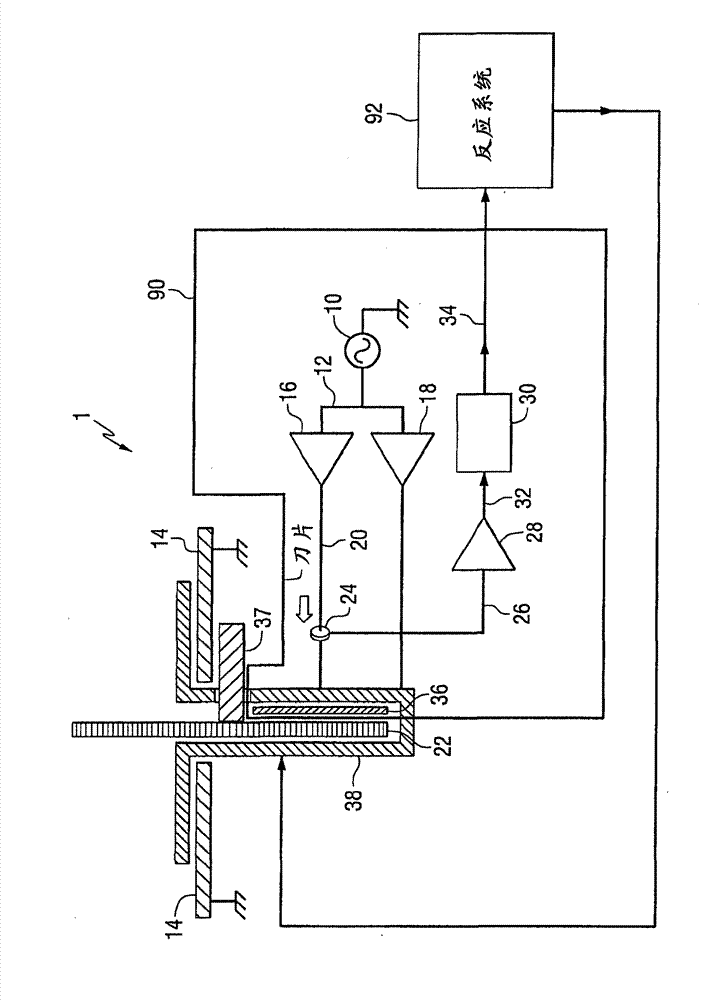

[0016] According to various embodiments, the present invention is directed to a power tool, such as a table saw, having a movable blade. The power tool includes a capacitive sensing based detector system for detecting contact between a blade and an object. The reaction system communicates with the detection system and, when triggered by the detection system, conducts a state mitigation reaction.

[0017] exist figure 1 An embodiment of a detection system based on capacitive sensing according to the present invention is shown in the idealized diagram of FIG. 1 , wherein a detection system 90 implemented in a table saw 1 is shown. It should be appreciated that the detection system 90 may be used with other types of tools and machines, such as other types of power tools, particularly tools and machines with exposed, movable (eg, rotating and / or reciprocating) blades, and These implementations are within the scope of the present invention. For example, detection system 90 may a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com