Method for producing a disintegrating roller housing of an open end spinning machine and disintegrating roller housing

A technology of opening roll and free end is applied in the field of opening roll shell, which can solve the problems of high production cost and unfavorable manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

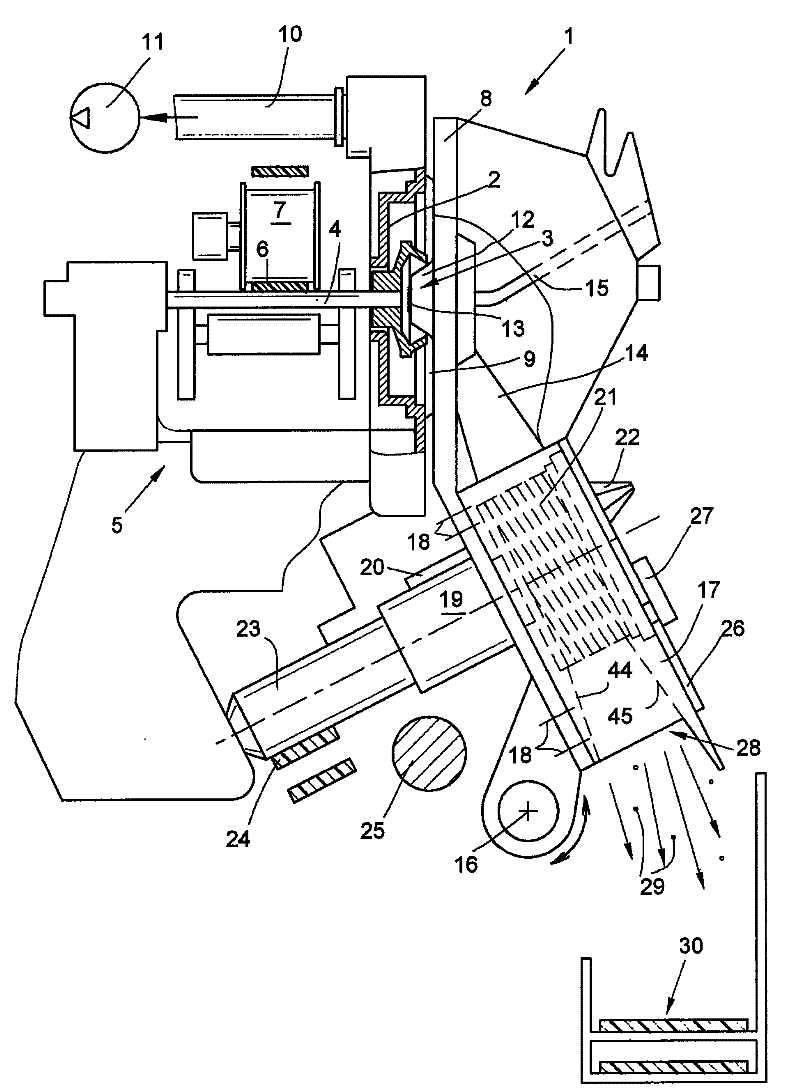

[0021] figure 1 An open-end spinning device, generally designated by the reference numeral 1 , is shown in side view, on which an opening roller housing 17 produced by the method according to the invention is used.

[0022] As shown in the figure, such an open-end spinning device 1 has a rotor housing 2 in which a spinning cup 3 rotates at high speed. In this case, the spinning cup 3 is supported with its rotor shaft 4 in the wedge support of the bearing disc seat 5 and is acted upon by a tangential drive belt 6 in the longitudinal direction of the machine, which is adjusted by a pressure roller 7 .

[0023] The rotor cup housing 2 , which is open to the front, is closed during operation by a rotatably mounted cover 8 , in which a channel plate (not shown in detail) with a seal 9 is machined. The rotor housing 2 is also connected via a corresponding vacuum line 10 to a vacuum source 11 which generates the spinning pressure (spinnunterdruck) required in the rotor housing 2 dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com