Improved intermittent type pressure pulp screening machine

A technology of pulp sifter and pressure sieve, which is applied in textiles, papermaking, fiber raw material processing, etc., can solve problems such as downtime, and achieve the effects of reducing power consumption and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

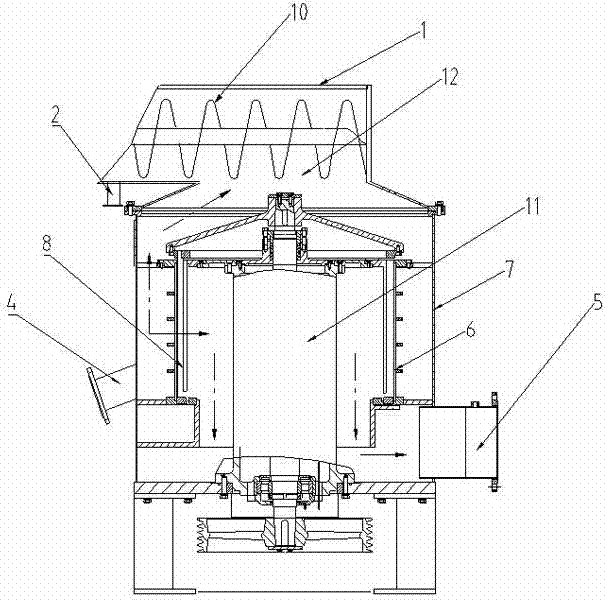

[0036] The pressure screen machine described in this embodiment is as figure 1 As shown, the pressure screen machine includes: a housing 7;

[0037] A sieve drum 6 is arranged inside the housing 7, and a rotating rotor shaft driven by a power drive device is arranged inside the cavity of the sieve drum 6, and a rotor rotor 11 is arranged on the rotating rotor shaft, and the rotor rotor 11 is located in the cavity of the sieve drum 6, and the rotor rotor 11 is provided with a rotor 8 capable of relative circular motion with the sieve drum;

[0038] A slurry inlet ( figure 1 It is a cross-sectional view of the pressure screen, and the pulp inlet is not shown in the figure because it is not on the cross-section);

[0039] A side of the sieve drum 6 is communicated with a fine pulp outlet 5;

[0040]In the housing, along the conveying direction of the light slag, a spiral slag discharger is connected to the housing near the slag discharge end 12 of the screen drum 9; the slag i...

Embodiment 2

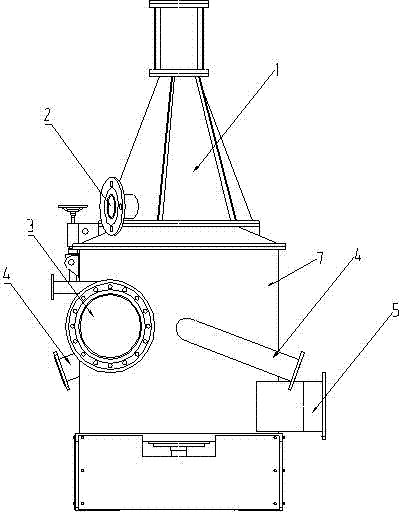

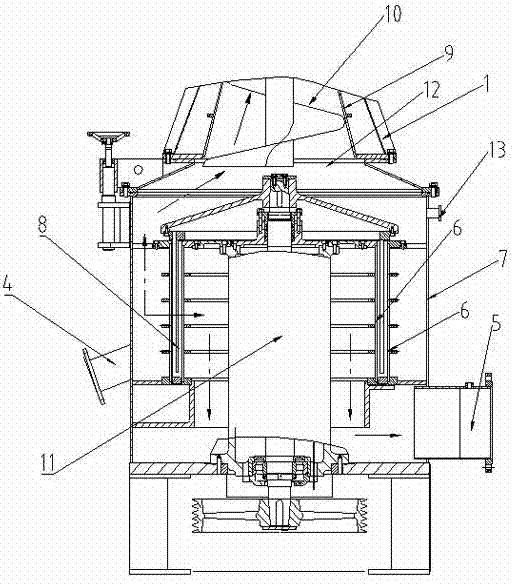

[0046] The pressure screen machine described in this embodiment is as figure 2 and image 3 As shown, the pressure screen machine includes: a housing 7;

[0047] A sieve drum 6 is arranged inside the housing 7, and a rotating rotor shaft driven by a power drive device is arranged on the central axis of the sieve drum 6, and a rotor rotor 11 is arranged on the rotating rotor shaft. The rotor 11 is provided with a rotor 8 capable of relative circular motion with the screen drum;

[0048] The sieve drum 6 in this embodiment is divided into two layers, and the two-layer pressure sieve drum 6 is respectively located on the inner side and the outer side of the rotor 8; as an optional embodiment, the two-layer pressure sieve can also be It is arranged on the same side of the rotor 8.

[0049] A slurry inlet 3 is provided on the shell 7 relative to the screen drum 6;

[0050] A side of the sieve drum 6 is communicated with a fine pulp outlet 5;

[0051] In the housing, along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com