Air intake supercharging device of air-cooled diesel engine

A technology of diesel engine and intake boosting, which is applied in combustion engines, machines/engines, mechanical equipment, etc., can solve the problems of large internal force and wear of the engine, large exhaust gas and black smoke emissions, and shortened power life, etc. Achieve the effect of saving fuel, reducing exhaust gas and black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

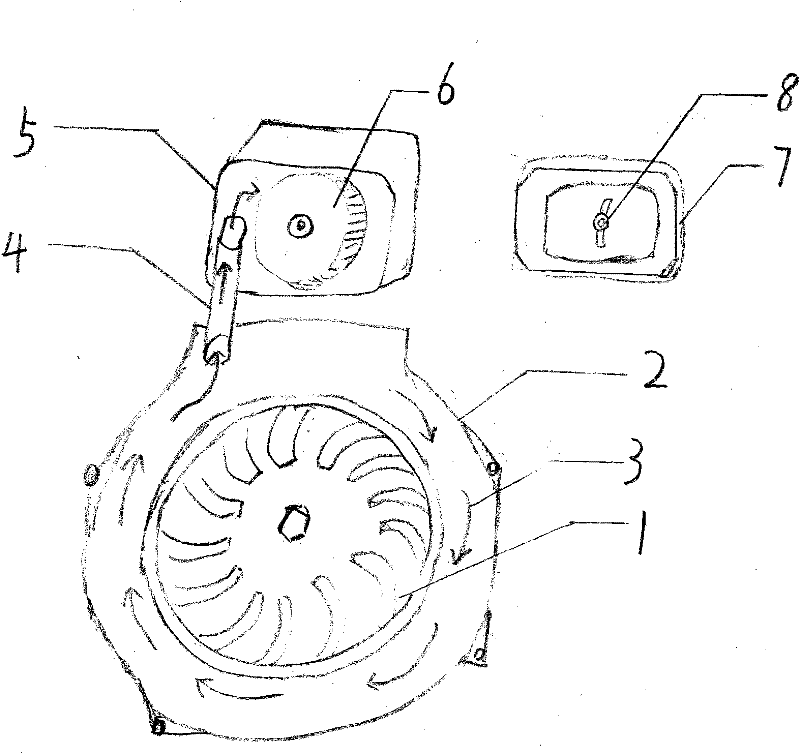

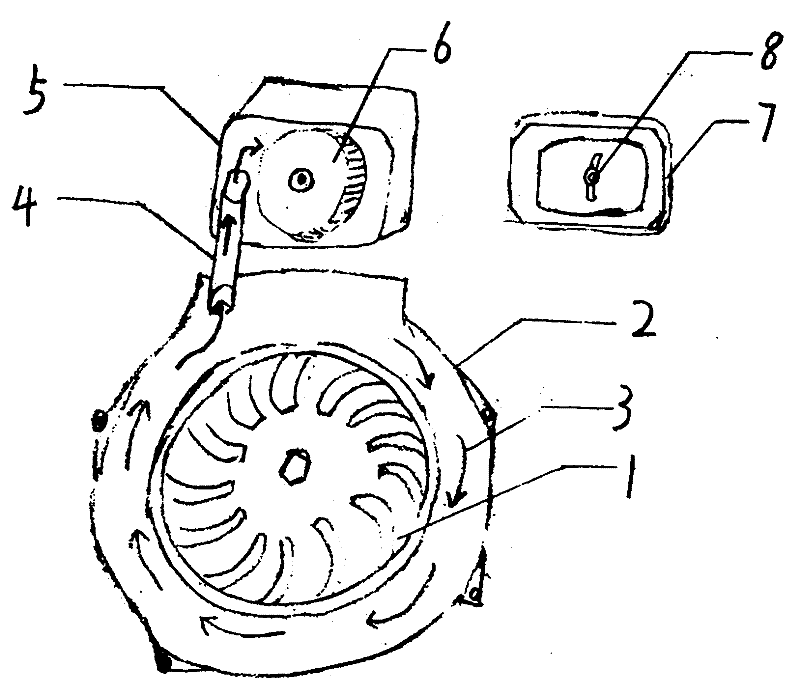

[0014] Such as figure 1 As shown, the patent of the present invention includes two parts of the flywheel of the air filter, which are connected by the intake guide pipe 4 between them. The flywheel 1 is installed in the flywheel hood 2, the air intake duct 4 is installed on the top of the flywheel hood 2 and connected with the air filter housing 5, the air filter element 6 is installed inside the air filter housing 5, and the air filter housing cover plate 7 is installed in the air The outer side of the filter housing 5 . Nut 8 is fixed on the center of the cover plate of the air filter case.

[0015] The invention is patented while the engine is running. The airflow of the running flywheel 1 enters the inner airflow of the flywheel windshield 2, and the airflow 3 enters the air filter shell through the intake guide pipe, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com