Pipeline heating connector

A pipeline and joint body technology, which is applied in pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that cannot be fully heated, cannot ensure the smooth flow of pipelines, and cannot circulate liquids, etc., to achieve heating Good effect, solve heating problem, high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

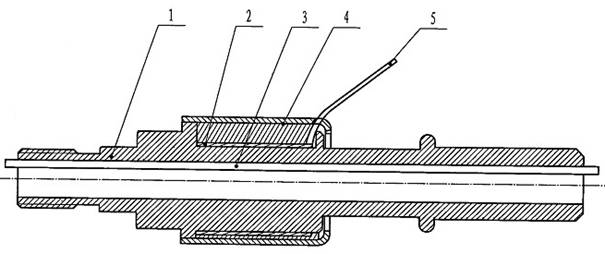

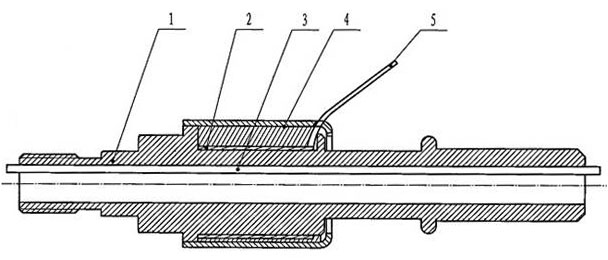

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a joint body 1, a heating body 2 is arranged on the joint body 1, a protective layer 4 is arranged on the outside of the heating body 2, and a power line 5 is connected to the heating body 2; a heat conductor 3 is arranged on the inner wall of the joint body 1, and a 1 The material is 304 stainless steel, and the heating element 2 is made of PTC, electric heater or nickel-chromium alloy.

[0017] Using the pipeline heating joint of the present invention, according to different pipelines, design the pipeline heating joint of specific installation size, install it on the inlet and outlet of the tank or pump, turn on the power, and turn on the power to heat. Therefore, the beneficial effects of the present invention are: the pipeline heating joint is easy to use, can be used immediately after being connected to the power supply, has a good heating effect, can directly h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com