Microblaze soft core technology-based LED (Light Emitting Diode) large-screen asynchronous control system

An asynchronous control and large-screen technology, applied in the direction of instruments, static indicators, etc., can solve the problems of large speed difference, difficult to improve the speed, unfavorable application and promotion, etc., to improve processing efficiency, alleviate inefficiency, reduce The effect of direct interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

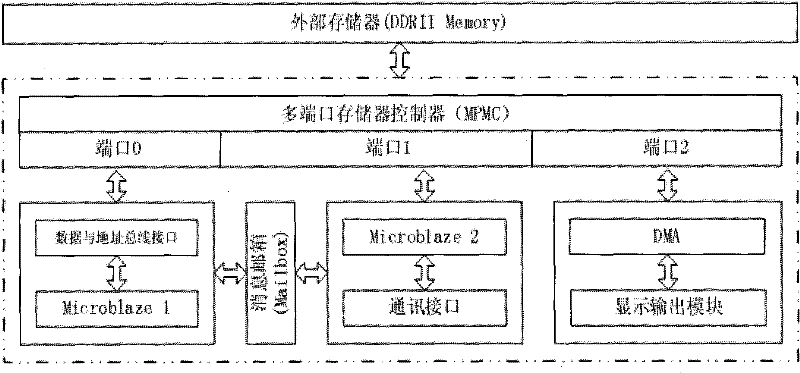

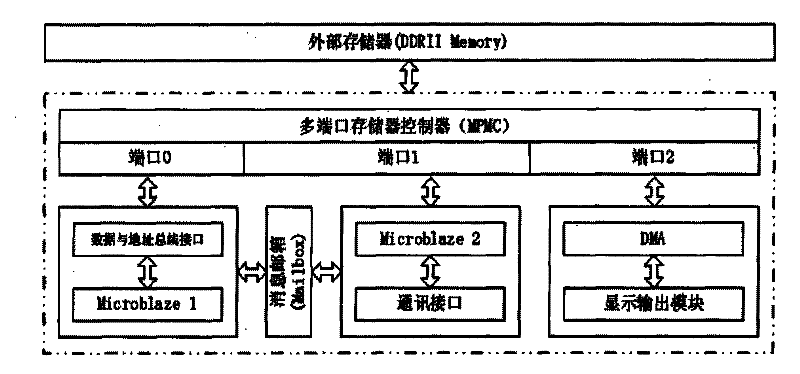

[0025] The core design principle of the large LED screen asynchronous control system of the present invention is based on Xilinx soft-core technology. Xilinx's MicroBlaze soft core is a powerful, flexible embedded soft processor, and its powerful user-defined logic functions greatly facilitate system design.

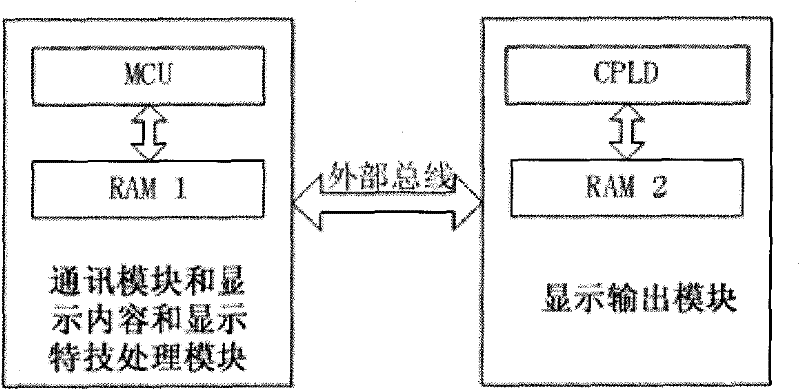

[0026] Such as figure 2 As shown, in a specific embodiment of the present invention, it at least includes: a communication interface module for realizing communication between the control system and external equipment; a display content and special effect processing module for display content and display special effect processing; It is a display output module that converts the display content into the interface timing output of the LED large screen.

[0027] The control system also includes a first Microblaze soft core for the display content and special effect processing module to realize display content and display special effect processing; a second Microblaze soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com