Light-emitting devices and its forming method

A light-emitting device and light-emitting unit technology, applied in the structure of optical waveguide semiconductors, semiconductor devices, electrical components, etc., can solve the problems of increased cost and complexity, and the inability to improve light leakage efficiency, etc., to achieve low cost and increase light output area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

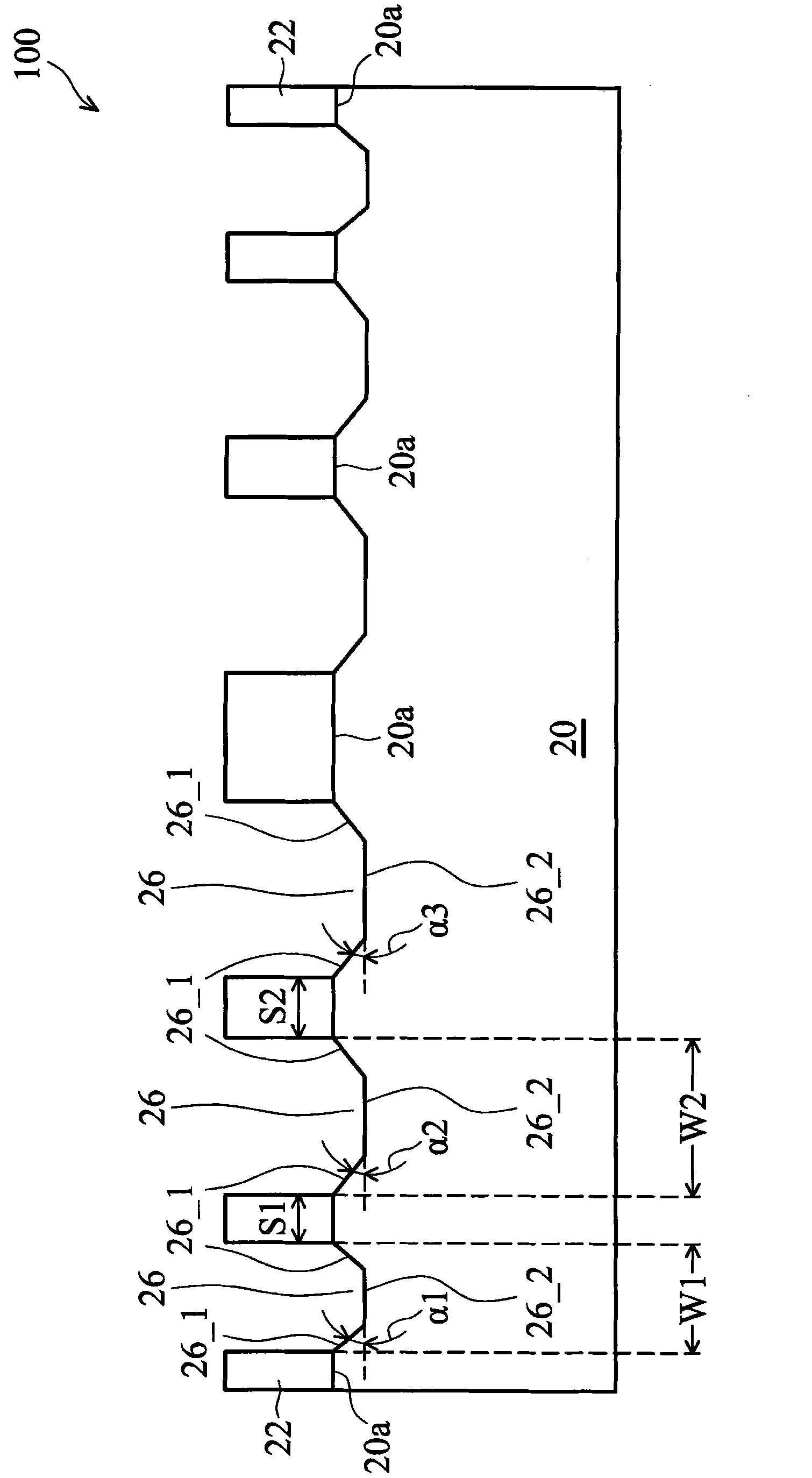

[0038] Hereinafter, a novel light-emitting device and a method of forming the same according to an embodiment of the present invention will be described. And the figure is shown in the middle stage of the manufacturing process in the embodiment. And then discuss the changes and operations of the embodiment of the present invention. In these different drawings and illustrated embodiments, the same reference numerals are used to represent the same elements.

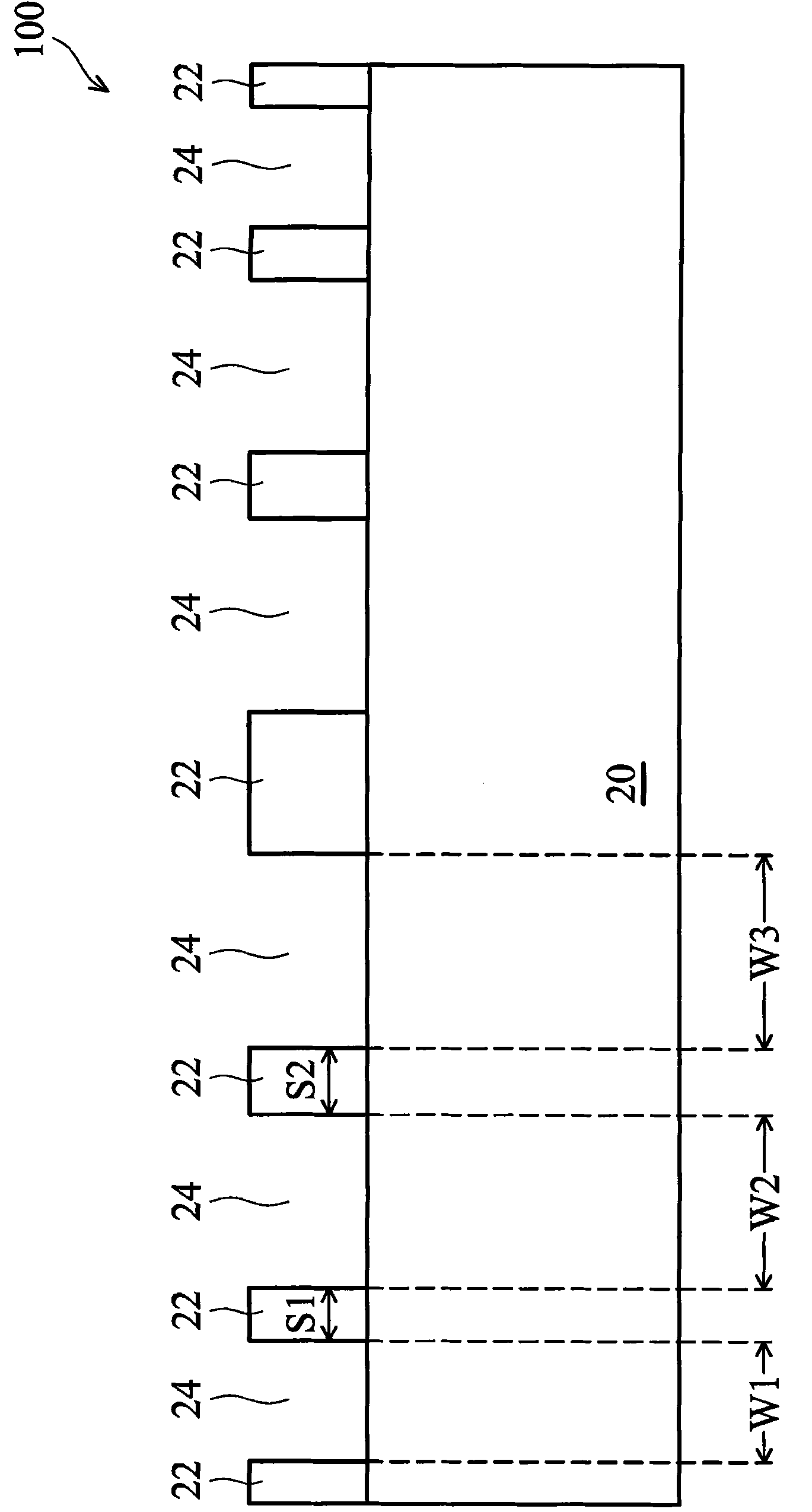

[0039] Please refer to figure 1 First, the chip 100 including the substrate 20 is provided. The chip 100 may be a part of an un-diced wafer including a plurality of identical chips. In one embodiment, the substrate 20 may be made of sapphire (Al 2 O 3 ) Formed. In other embodiments, the substrate 20 is a silicon-containing substrate, such as a silicon carbide substrate or a silicon substrate. In other embodiments, the substrate 20 includes a compound semiconductor material of group III and / or group V elements, or a well-k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com