Brushless double-fed motor

A doubly-fed motor and rotor technology, applied in the shape/pattern/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/pattern/structure of the winding conductor, etc. The problem of large harmonic leakage reactance, etc., to achieve the effect of coupling, air gap density and low harmonic content

Inactive Publication Date: 2011-09-21

ANHUI AOXUN INFORMATION TECH

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

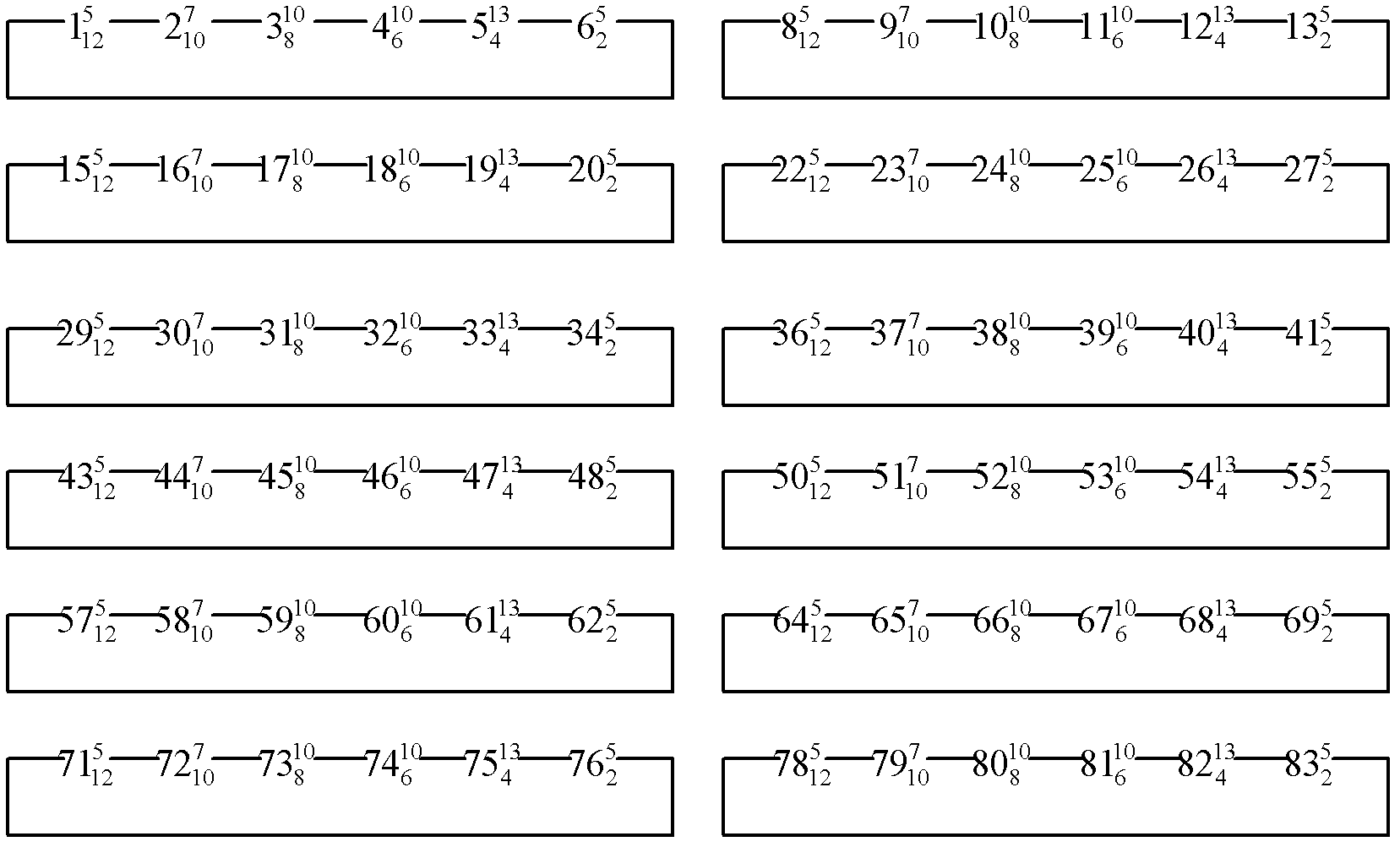

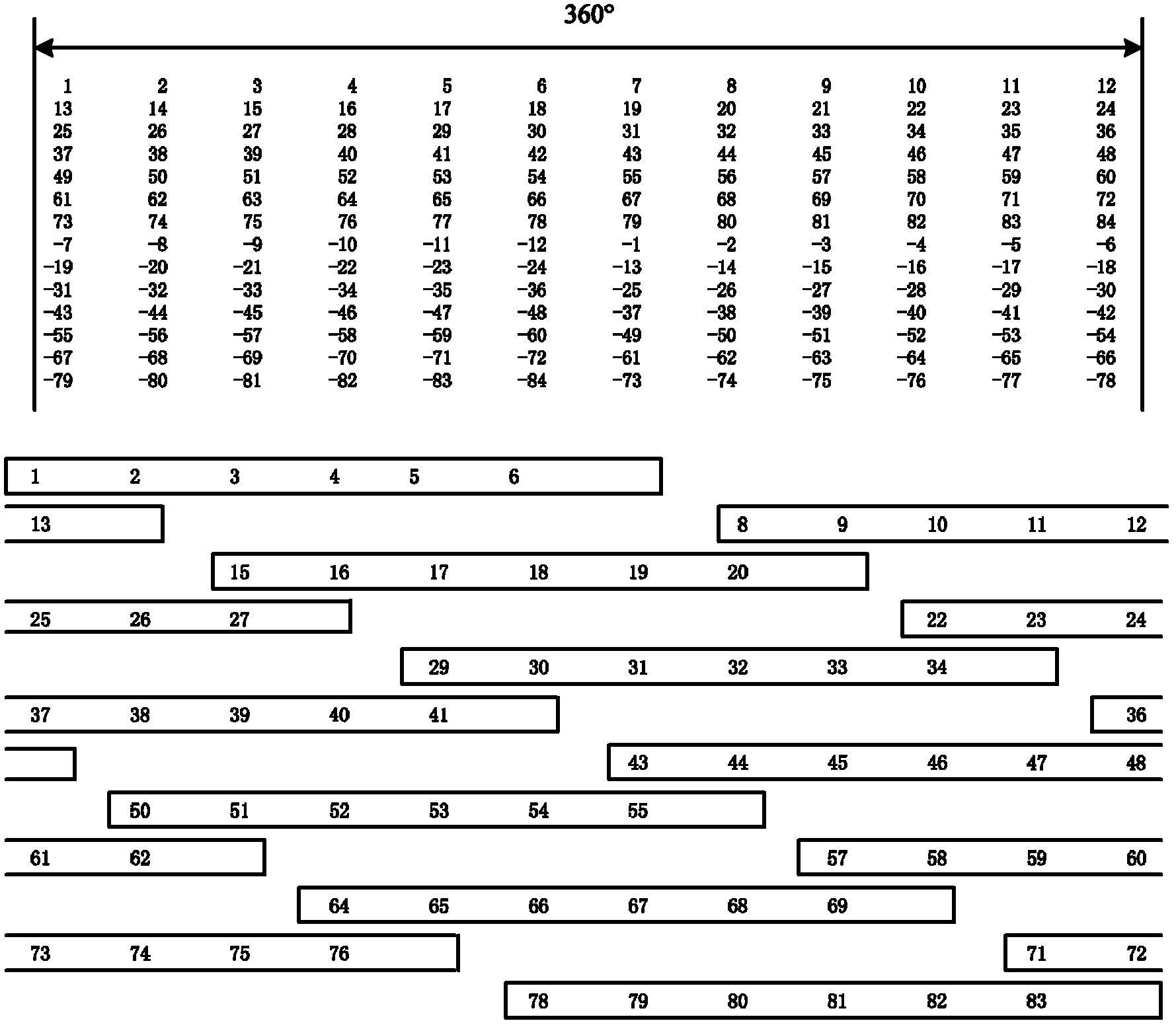

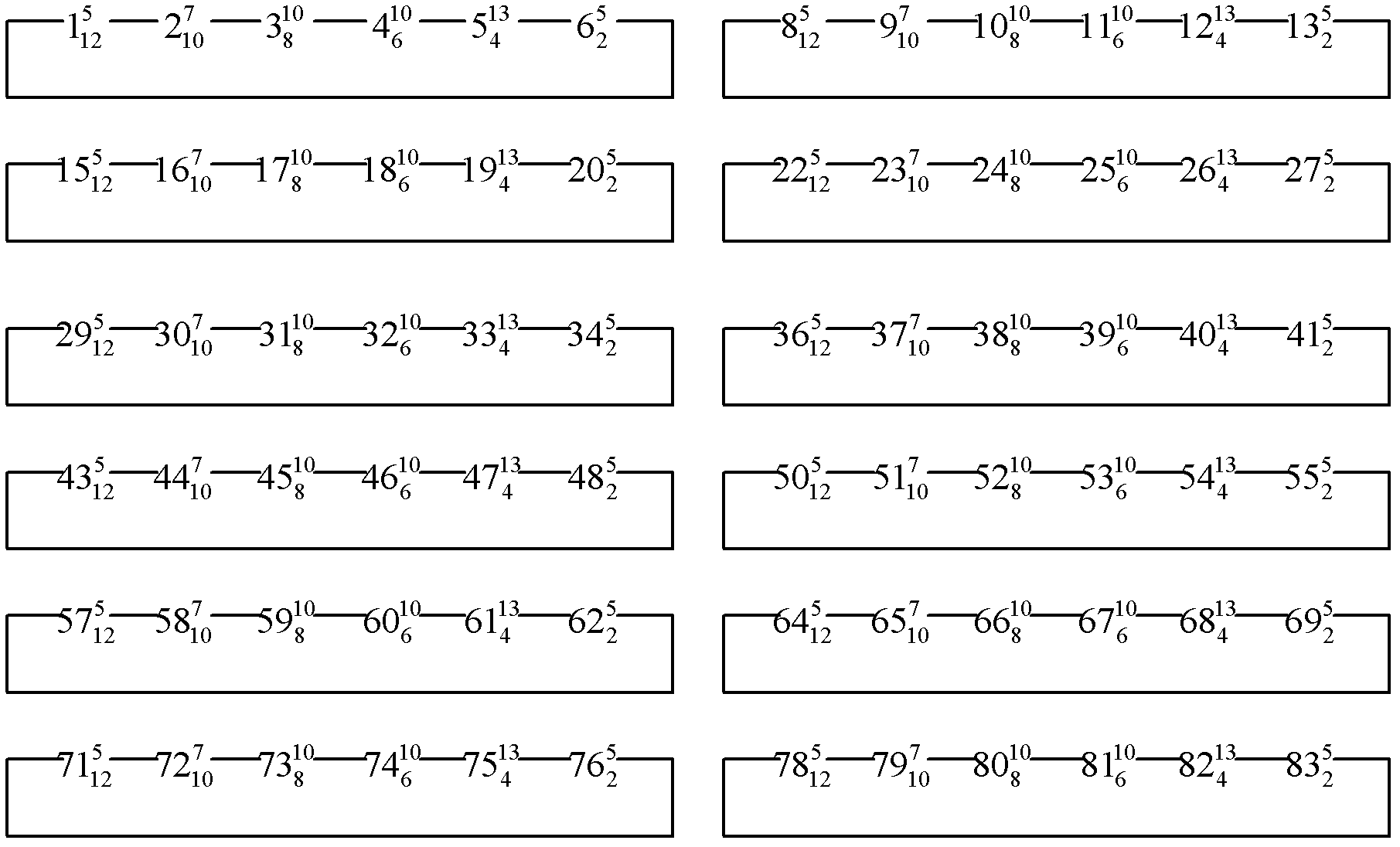

The special cage rotor is considered to be the most likely to be applied to large-capacity motors, but the existing special cage rotor windings are designed according to the "conjugate" principle, that is, the two poles of the rotor required for the brushless doubly-fed motor , the design retains the cage conductors whose induced potentials are in the same phase under the two numbers of poles, and removes the cage conductors of different phases, which will inevitably lead to low utilization of the rotor conductors and large harmonic content, resulting in low operating efficiency of the motor. Good realization of brushless doubly-fed motor rotor requirements

The existing special cage rotor winding usually adopts two winding methods, one is that the coils have equal span and the number of turns is distributed equally, and the other is that several groups of concentric and equal turns are distributed, and the span of the two winding methods is Neither the span nor the number of turns can flexibly change the coil span and number of turns according to the harmonic principle, so there are many coils with different phases of induced potentials between the rotor winding and the stator's power winding P1 and control winding P2, so the high-order magnetic The percentage of momentum harmonics is large, and the corresponding rotor winding harmonic leakage reactance is also large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs and relates to the technical field of motors, in particular to a brushless double-fed motor. The key is that the turns of coils in the largest slot number set are symmetrically distributed according to an arched pattern: the turns of outward coils of the innermost layer are first rapidly increased and then decreased gradually. According to the tooth harmonic theory, the rotor windings of the present equal turns are changed that the coils in the largest slot number set of the rotor winding which are symmetrically distributed according to the arched law, so that the higherharmonic of the rotor magnetic motive force is reduced; the rotor windings using the coil distribution method can realize the couplings between a power winding P1 and a control winding P2 of a statorand the rotor windings well; and the air-gap dense harmonic content is lower.

Description

A brushless doubly-fed motor technical field The invention relates to the technical field of motors, in particular to a brushless double-fed motor. Background technique If the brushless double-fed motor wants to have better performance, the key lies in the rotor. In recent years, the rotor structures of brushless double-fed motors mainly include reluctance rotors and special cage rotors. The working principle is that the two pole logarithmic magnetic fields generated by the stator windings can simultaneously generate induced potentials in the same rotor circuit. At present, it is believed that the bottleneck restricting the practical application of brushless doubly-fed motors lies in the performance of the rotor windings. The special cage rotor is considered to be the most likely to be applied to large-capacity motors, but the existing special cage rotor windings are designed according to the "conjugate" principle, that is, the two poles of the rotor required for the brus...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K1/26H02K3/12

Inventor 阚超豪陈凌岳阚立琦

Owner ANHUI AOXUN INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com