Method and device for purifying and recycling organic garbage from kitchen

A recycling method and recycling device technology, applied to organic fertilizers, fertilization devices, organic fertilizer equipment, etc., can solve the problems of waste of resources, public hazards, etc., and achieve the effects of eliminating vibration transmission, small size, and eliminating environmental odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

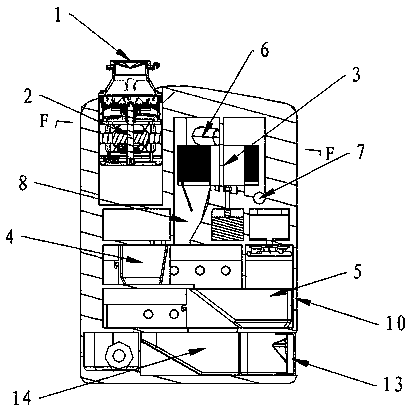

[0028] like Figures 1 to 10 Shown, a kind of kitchen organic waste purification recovery method of the present invention comprises the following steps:

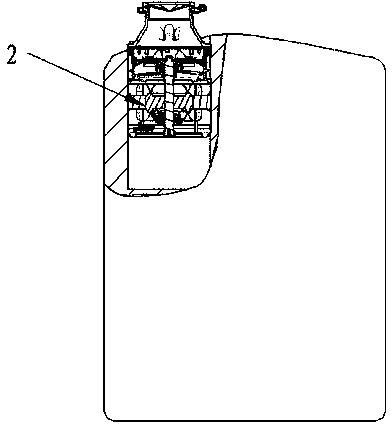

[0029] Step 1: Enter the organic waste generated in the household or kitchen from the drain of the sink 9 through the organic waste inlet 1 of the crushing system 2 into the crushing system 2 for crushing;

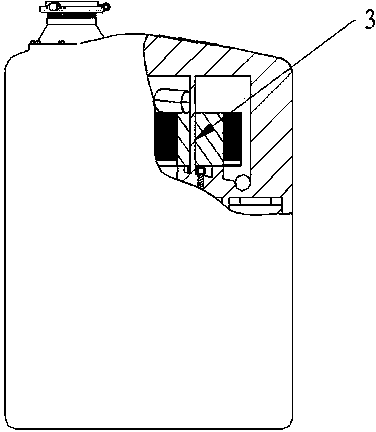

[0030] Step 2: Send the crushed organic waste to the dehydration and separation operation room 3 through the first channel 6 for dehydration treatment. Through the dehydration process, a large amount of water is separated, and the separated water is discharged into the sewer through the second channel 7 for dehydration. The final organic waste is sent into the fermentation container 4 by the third passage 8;

[0031] Step 3: adding an appropriate amount of EM bacterial agent into the fermentation container 4 to carry out fermentation operation;

[0032] Step 4: Send the fermented organic waste through the outlet of the...

Embodiment 2

[0035] like Figures 1 to 10 As shown, a kitchen organic garbage purification and recovery device of the present invention includes a crushing system 2 with an organic garbage inlet 1 installed in a closed casing 10, a water removal and separation operation room 3, a fermentation container 4, and a drying and sterilization operation room 5 And a storage container 14 with a hatch 13, the airtight casing 10 is arranged under the water tank 9, and the water outlet of the water tank 9 is connected with the garbage inlet 1 of the pulverizing system 2 through an air-stop return elbow. The crushing system 2 communicates with the inlet of the dehydration and separation operation chamber 3 arranged below it through the first passage 6; the water outlet of the dehydration separation operation chamber 3 communicates with the sewer pipe through the second passage 7, and the outlet of the dehydrated matter passes through The third channel 8 is communicated with the inlet of the fermenting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com