Mortar-free inside and outside wall brick

A mortar-free and wall-tile-free technology, applied in covering/lining, construction, building construction, etc., can solve the problems of increasing construction time and construction cost, increasing construction cost, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

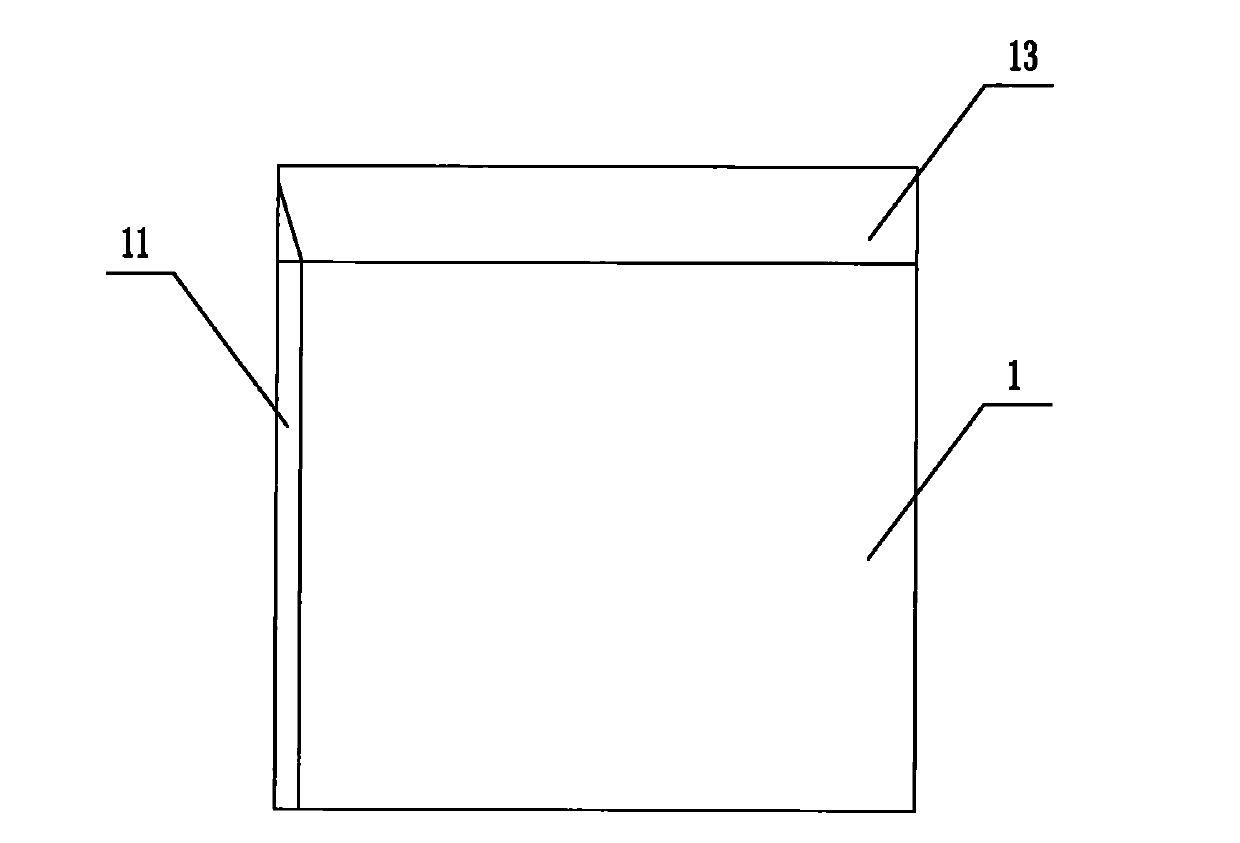

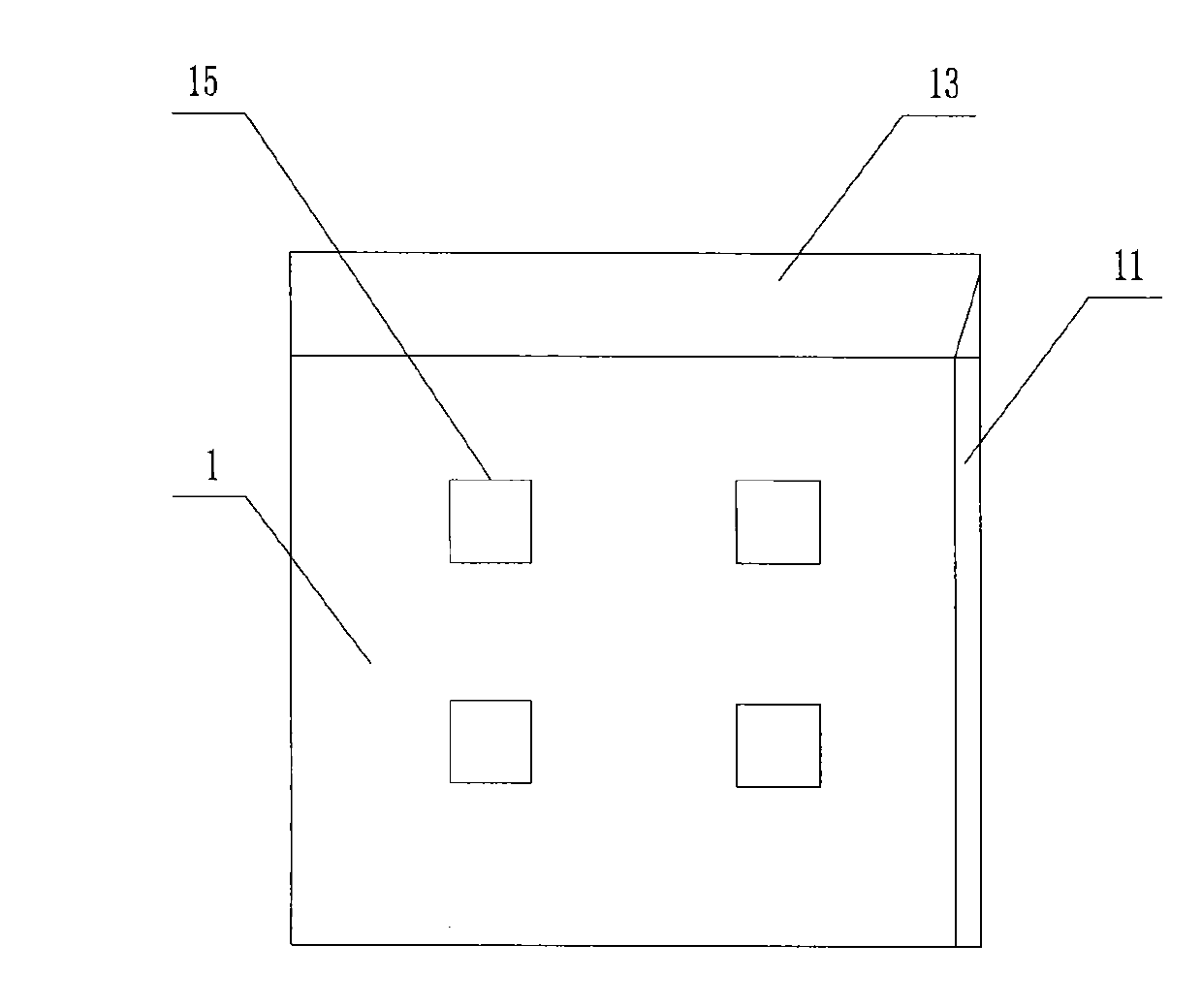

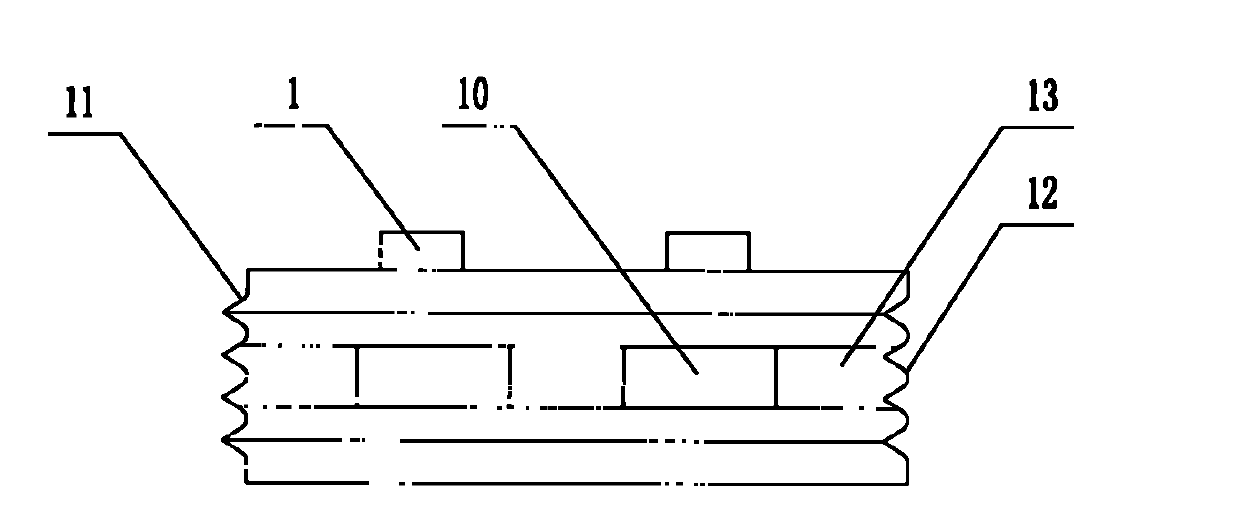

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a mortar-free interior and exterior wall brick, which includes a main body of a hollow brick 1, two hollow holes 10 of the hollow brick 1 run through the upper and lower surfaces, and the left and right sides of the hollow brick 1 are provided with corrugated strips that fit together. The grooves 11 and 12 are provided with protrusions 13 and grooves 14 that can be fitted with each other on the upper and lower surfaces. The rear surface of the hollow brick 1 is provided with a protrusion 15 that can increase the bonding strength with concrete. On the front surface of the hollow brick 1 Set with text pattern.

[0017] During the pouring construction of the inner and outer walls, it is only necessary to adjust the formwork spacing according to the thickness of the hollow brick 1, and then the hollow brick 1 is assembled and installed along the inner surface of the formwork in...

Embodiment 2

[0019] The structure of the mortar-free interior and exterior wall bricks of this implementation is basically the same as that of Embodiment 1, the difference is that: the convex head 15 on the back surface of the hollow brick is canceled, and patterns or characters are also arranged on the back surface. During the construction of the inner wall, it is only necessary to directly assemble the hollow bricks of the present invention into a heat-insulating wall in such a manner that the upper and lower sides are fitted together, and the left and right sides are fitted together.

[0020] In order to improve the bonding strength between the hollow brick and the wall concrete, a groove or a combination of a protrusion and a groove can also be arranged on the rear surface of the hollow brick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com