Tunnel lining trolley with push-pull end die and secondary tunnel lining pouring method implemented by same

A lining trolley and secondary lining technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., to achieve the effect of ensuring construction quality, improving efficiency and far-reaching significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

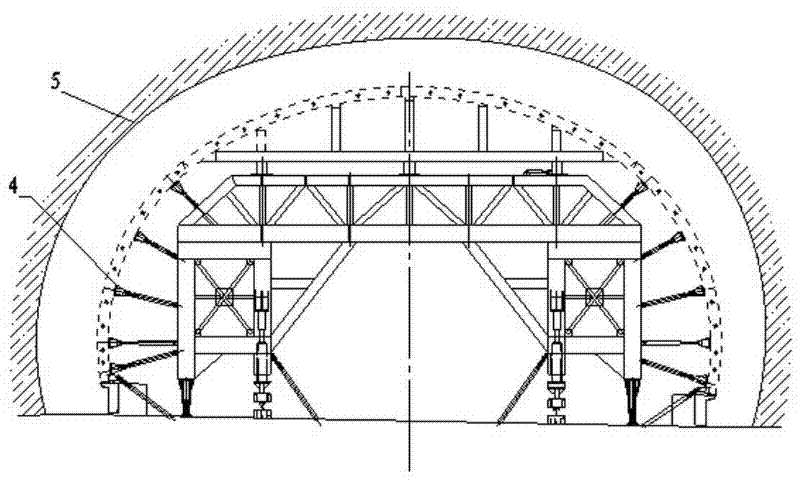

[0023] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

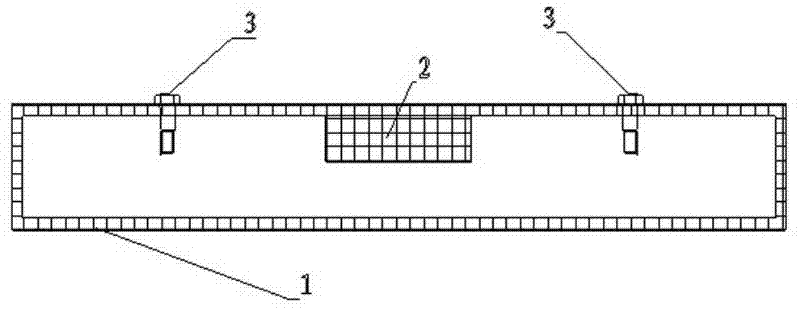

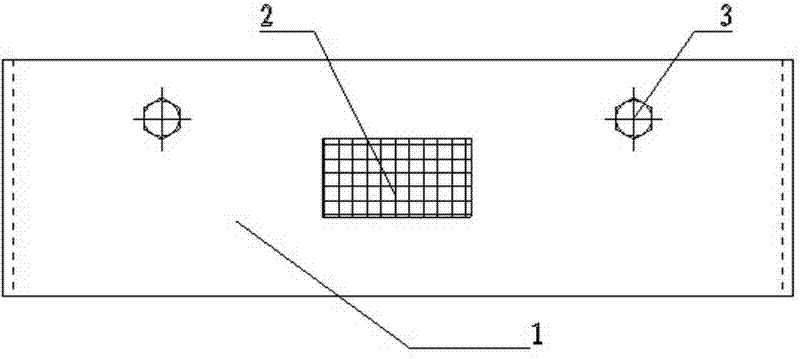

[0024] A tunnel lining trolley with a push-pull end form, including a lining trolley, a number of adjacent guide steel frames 1 are sequentially welded in the peripheral direction of the rear end of the lining trolley, and each guide steel frame 1 is provided with a Relatively its sliding also can block steel formwork 6 relative to its fixed end.

[0025] The upper side of the end-blocking steel formwork 6 is provided with a wave-shaped tooth structure 8, and the upper frame surface of the guide steel frame 1 is pierced with a compression bolt 3 perpendicular to the end-blocking steel formwork 6, and the guide steel frame 1 A reverse check device is installed at the bottom of the upper frame. The reverse backstop device includes a backstop steel plate 10 hinged on the bottom of the upper frame surface of the guide steel frame 1, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com