Cross compressor

A cross-type, compressor technology, used in mechanical equipment, machines/engines, liquid variable-capacity machines, etc., can solve problems such as uneven force, large vibration, compressor displacement, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

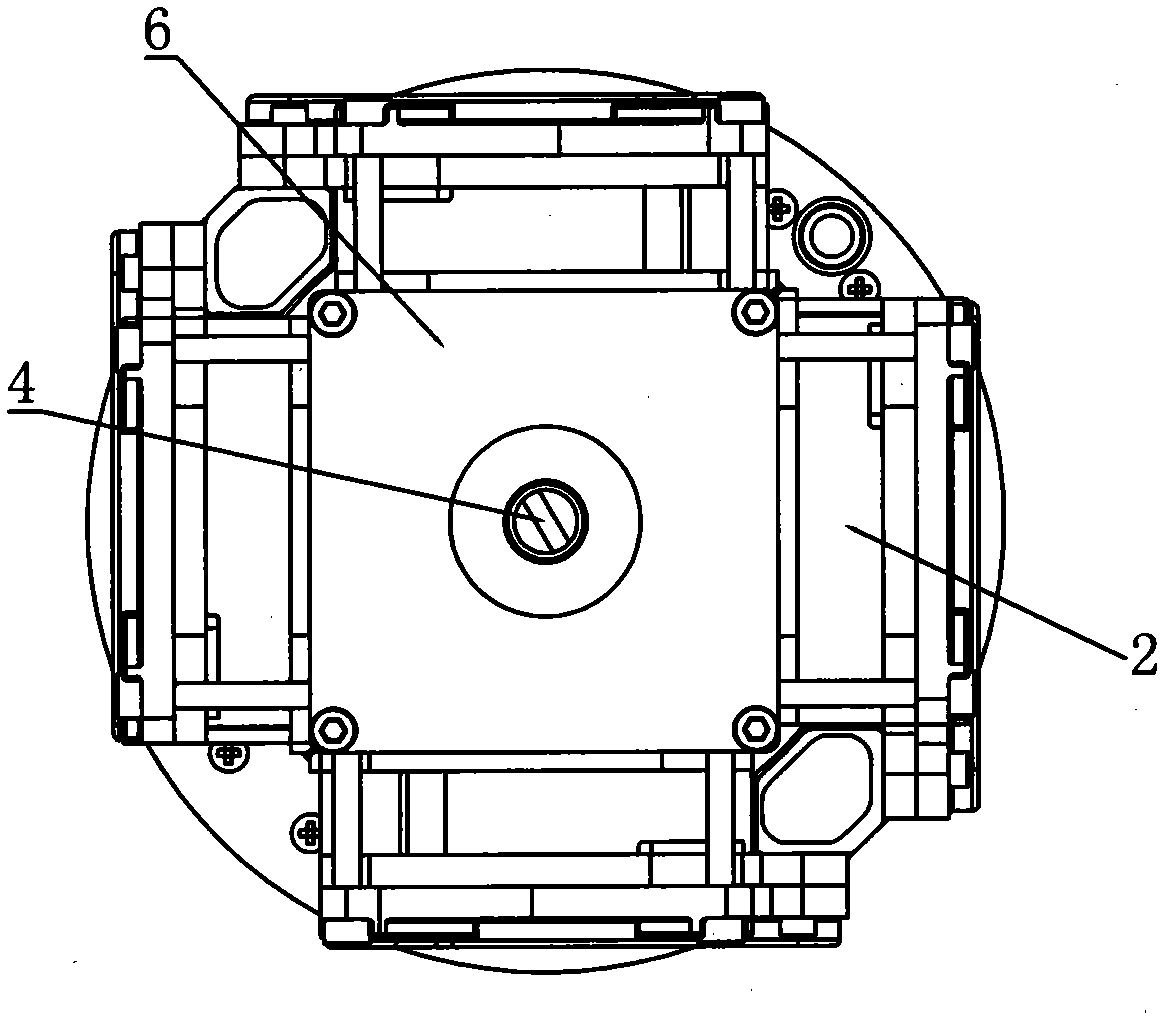

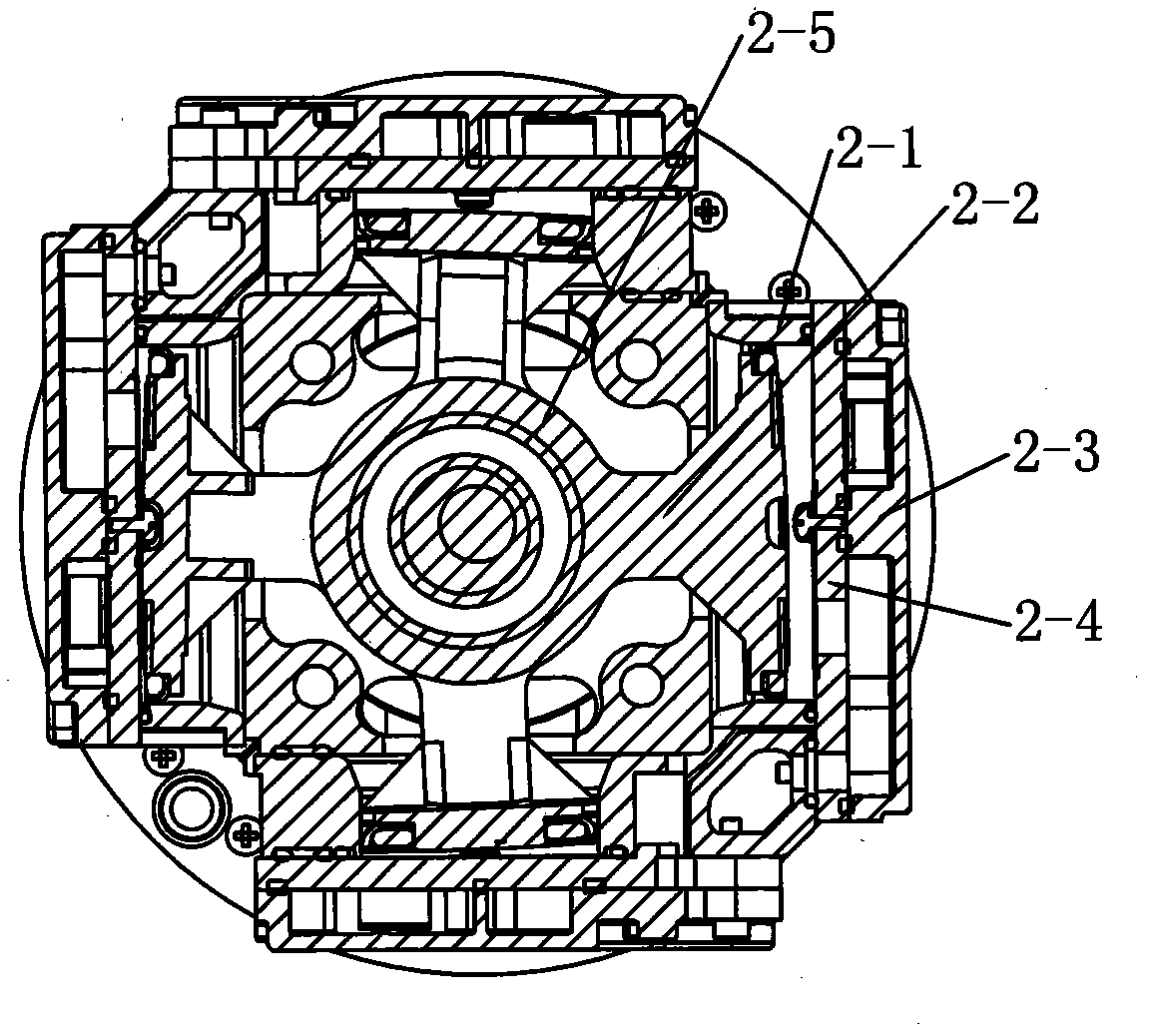

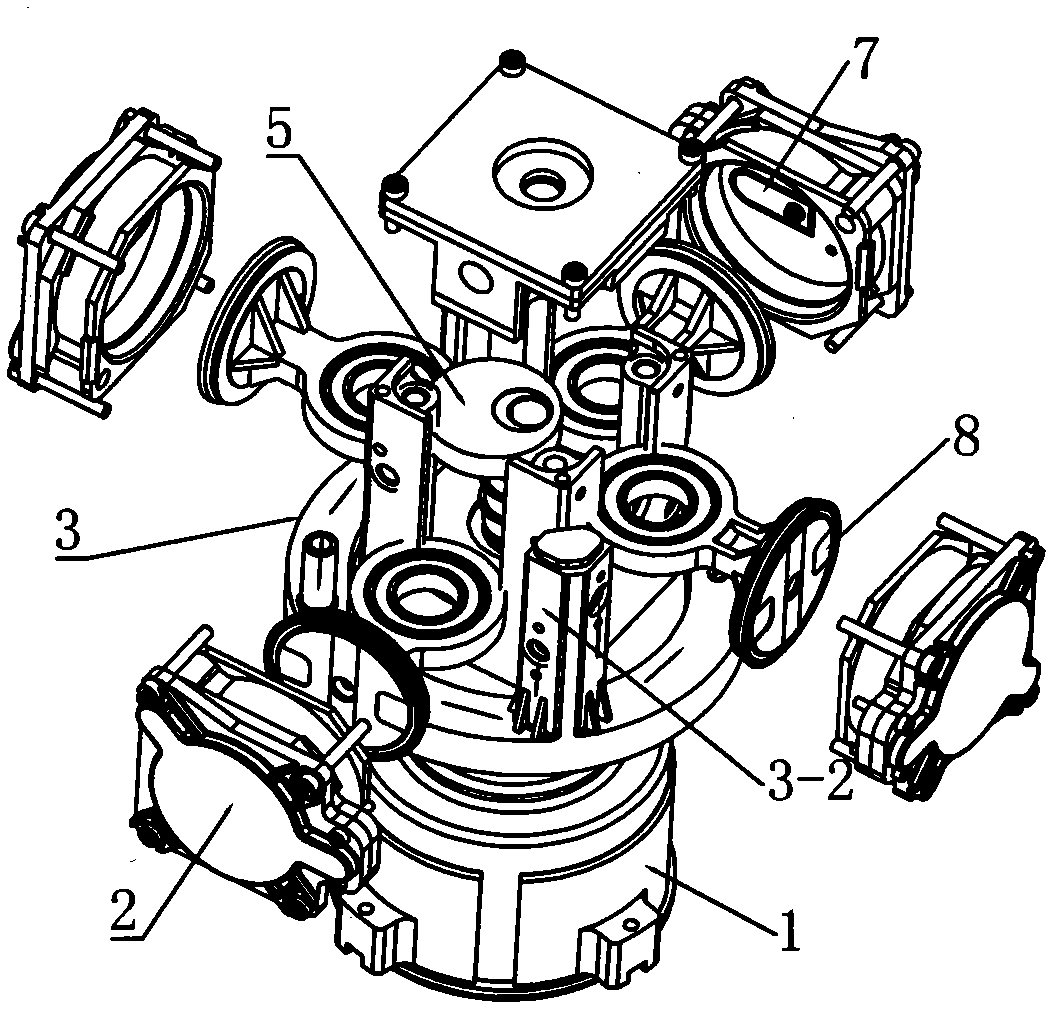

[0020] Such as Figure 1 to Figure 5 As shown, a cross-shaped compressor of the present invention includes a motor 1, a cylinder 2, and the cylinder 2 is mainly composed of a cylinder liner 2-1, a connecting rod 2-2 and a piston assembly 2-4 arranged on the connecting rod base 2-3. , the top of its motor 1 is provided with a base 3, four cylinders 2 are distributed in a cross shape on the base 3, and the connecting rod head 2-5 of each cylinder 2 is fixed on the motor shaft 4. The connecting rod heads of the four cylinders are stacked sequentially from top to bottom, and the four cylinders are placed in a ring at 90 degrees. An eccentric wheel 5 is sleeved on the motor shaft above the top cylinder. An air inlet 3-1 is arranged on the base 3, and the air inlet 3-1 is connected with an annular air inlet muffler mechanism, and the annular air inlet muffler mechanism is composed of several air inlet brackets 3-2, and the air inlet bracket 3-2 is in the form of Columnar, the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com