Heat energy aggregator

A polymerizer and thermal energy technology, applied in the field of high-efficiency thermal molecular polymerization devices, can solve the problems of short exchange time, large internal loss, and retention, and achieve faster exchange reaction speed, increased exchange area, and exchange time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

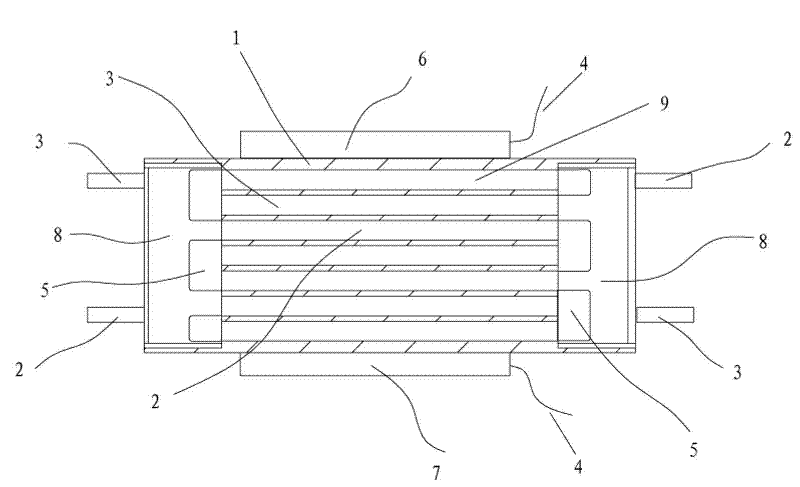

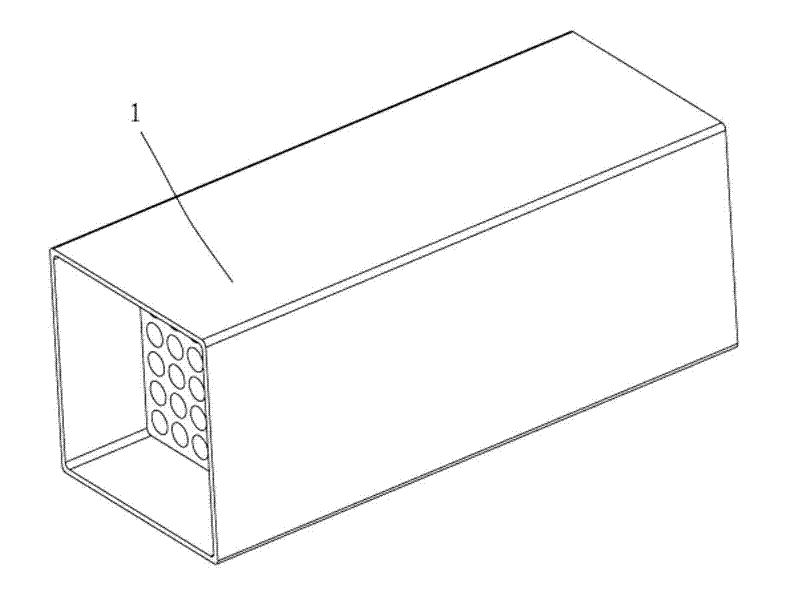

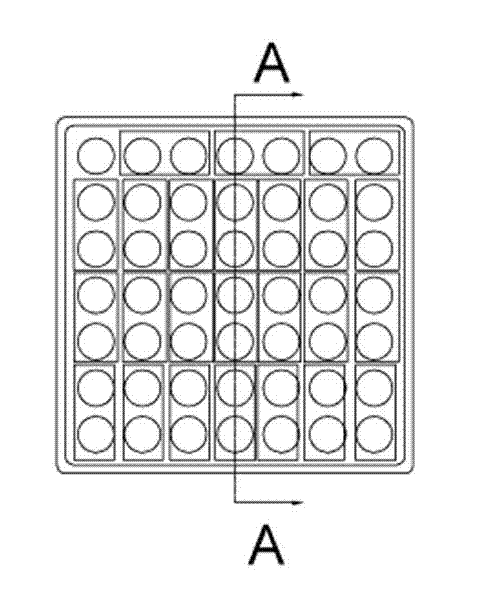

[0016] Such as Figure 1 to Figure 5 As shown, a kind of thermal energy aggregator, comprises the square shell shell 1 that two ends pass through with cavity structure, hot liquid pipe 2, cold liquid pipe 3 and power supply 4; Said hot liquid pipe 2 and cold liquid pipe 3 are honeycomb Arranged in the cavity of the outer casing 1 in a cross-shaped manner; at both ends of the outer casing 1, there are U-shaped connectors 5 that connect the hot liquid pipe 2 and the cold liquid pipe 3 into independent passages; Correspondingly, the upper and lower sides of the housing are equipped with positive and negative electromagnetic pole plates (6, 7) that can generate eddy current effects and fission effects after magnetically cutting the refrigerant in the hot liquid pipe 2 and the cold liquid pipe 3 in the housing; The two ends are respectively provided with a high temperature resistant cured adhesive layer 8 that seals the hot liquid pipe and the cold liquid pipe through the shell; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com