Built-in multi-fuel heating stove

A heating stove and embedded technology, applied in the field of embedded multi-fuel heating stoves, can solve the problems of difficulty in meeting heating demands in winter, waste of wood resources, unsuitable burning of straws, etc. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

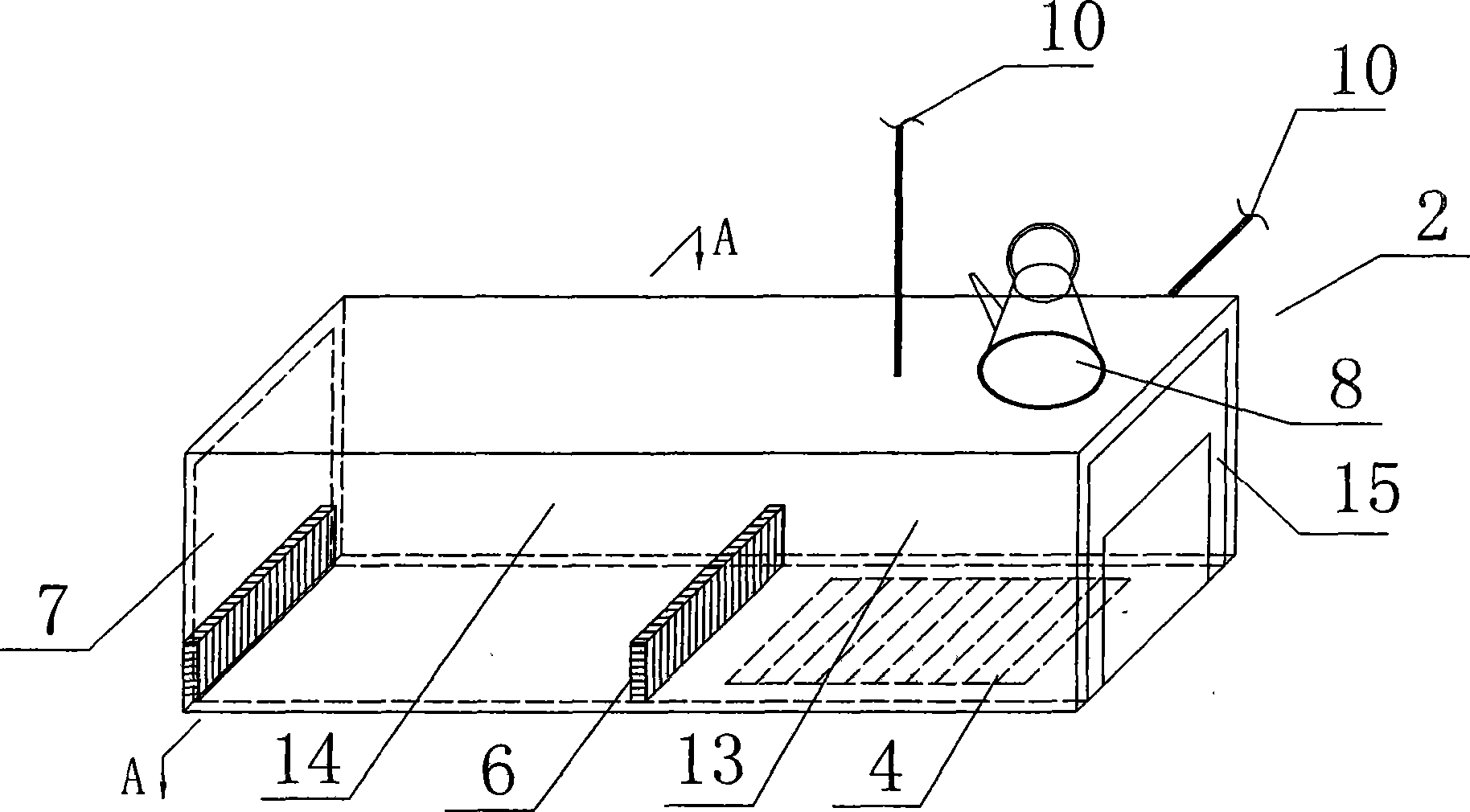

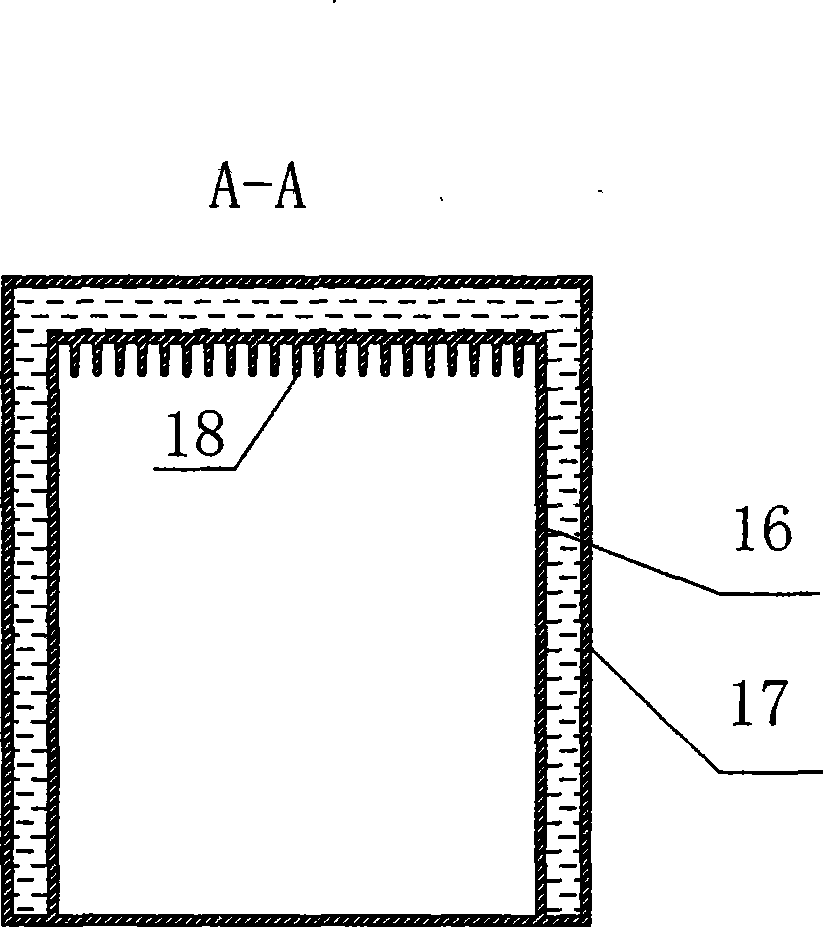

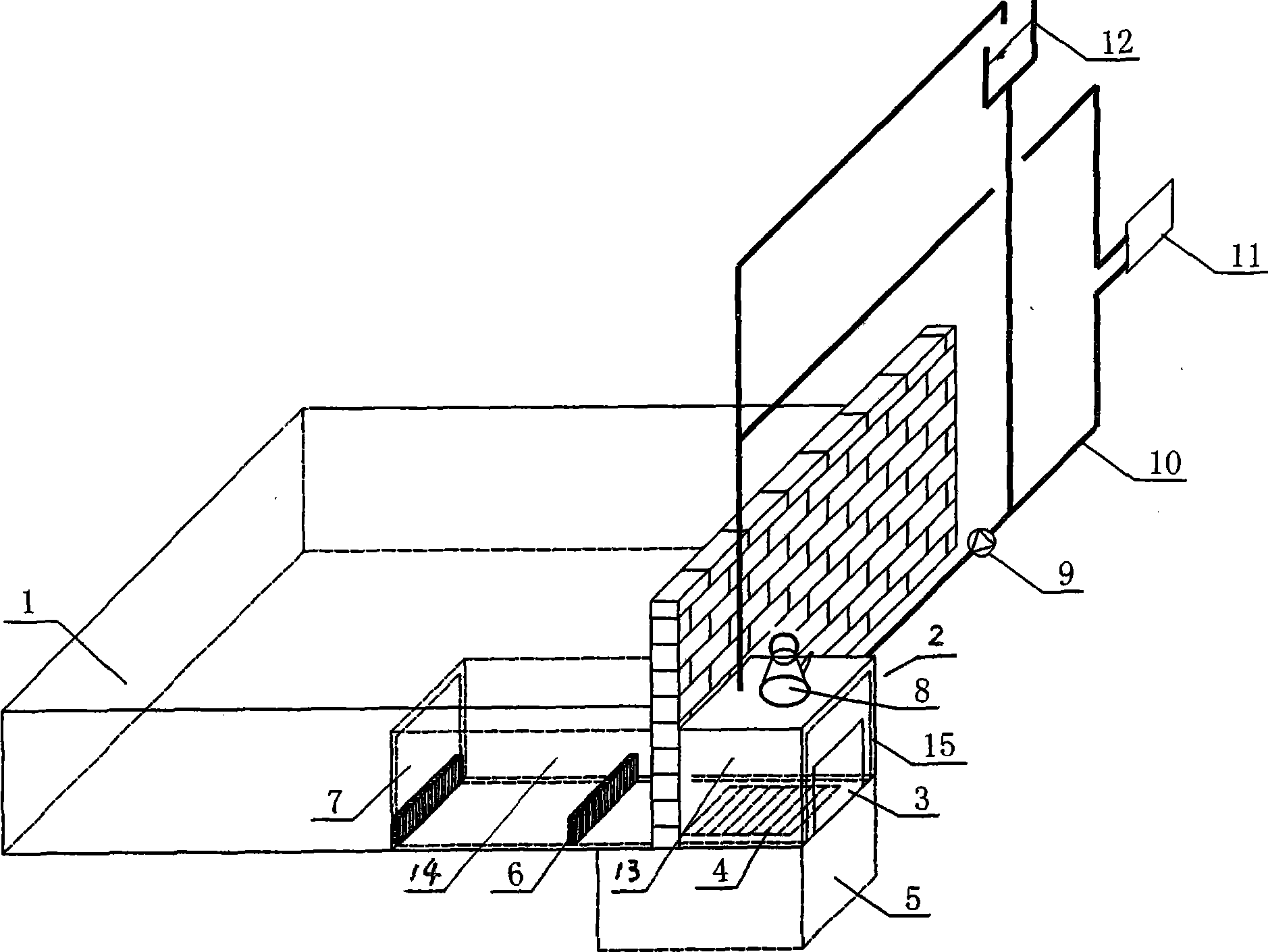

[0021] refer to Figure 1-3 , The embedded multi-fuel heating furnace has a body of heater 15, and the body of heater 15 is a closed water storage cavity formed by welding the inner and outer walls 16,17. A furnace 13 and a smoke passage 14 are arranged in the body of furnace 15, a fuel inlet 3 is provided on the exposed outside of the body of furnace 15, and a flue gas outlet 7 is arranged on the inside of the body of furnace 15 embedded in the kang body 1, and the fuel inlet 3. The furnace 13 , the smoke passage 14 and the flue gas outlet 7 are connected in sequence, and a furnace grate 4 is arranged at the bottom of the furnace 13 of the furnace body 15 . Several windshields 6 are built in the smoke passing channel 14 of the furnace body 15 . A cooker heating port 8 is provided on the exposed outer side of the furnace body 15 . A circulation pipeline 10 is arranged on the exposed outside of the furnace body 15 , and an expansion tank 12 , a radiator or a ground heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com