Headbox for a paper machine, board machine, pulp machine or equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

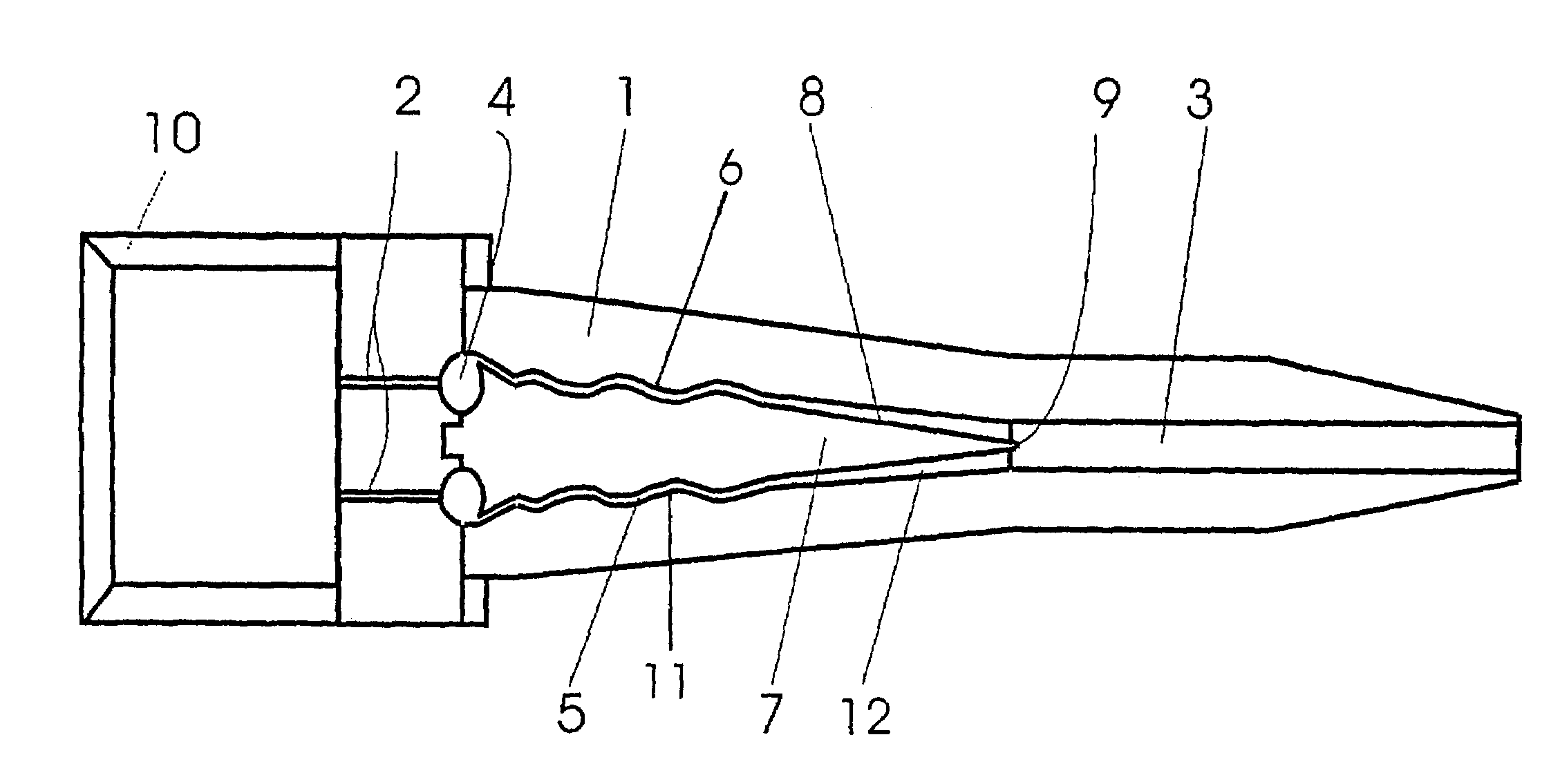

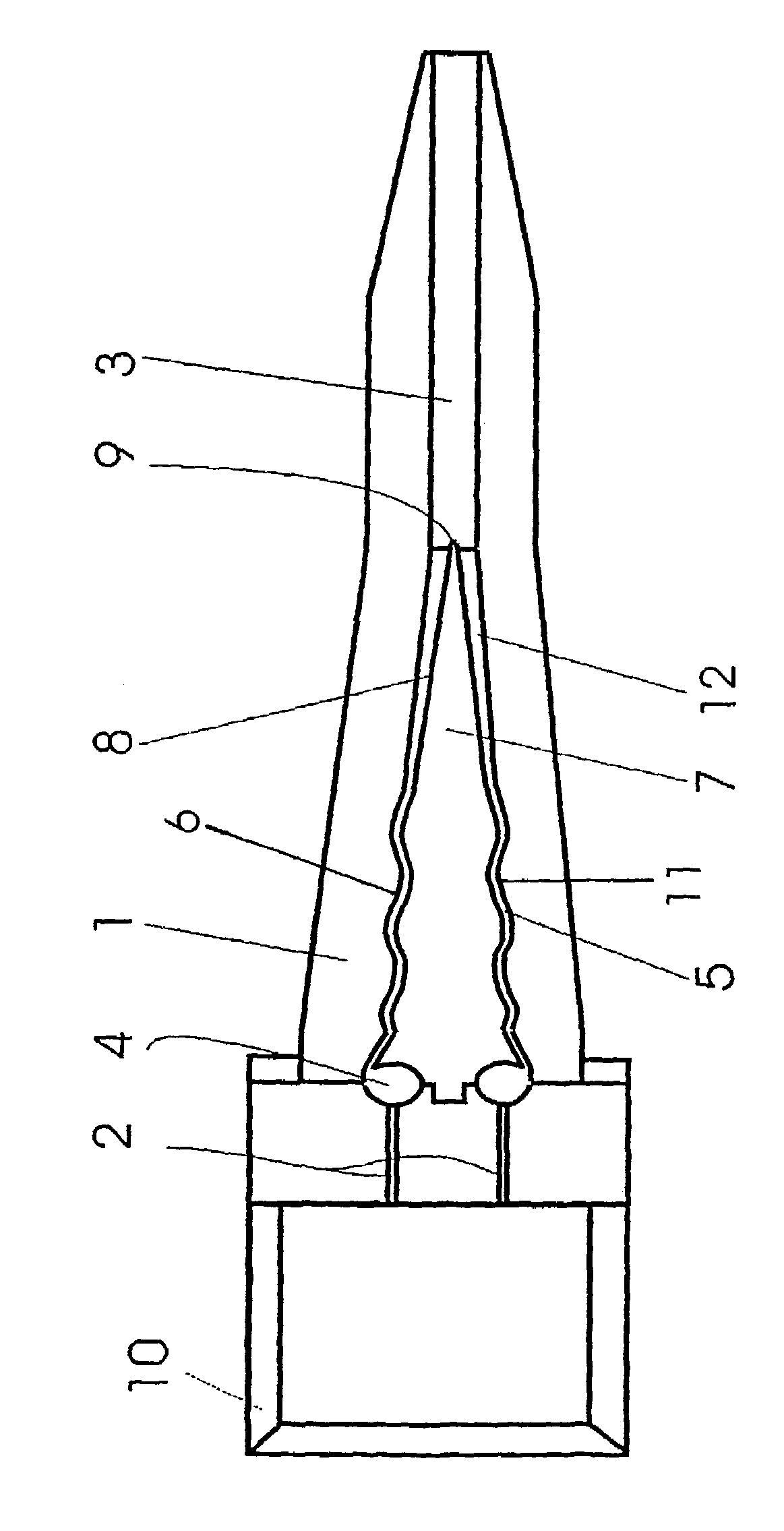

[0017]As shown in the FIGURE, the headbox according to the invention includes a turbulence part 1 which has a double passage structure and into which a fibre suspension flows from a fibre suspension distributor means 2, which is advantageously a tube bank, and a slice part 3. The fibre suspension flows passing as separate flows from each other in the turbulence part 1 are combined in the slice part 3, after which the combined fibre suspension flow passes to a forming section of a fibrous web (not shown in the FIGURE). Moreover, the headbox comprises an inlet header 10, by means of which the fibre suspension flow is distributed evenly across the entire width of the headbox.

[0018]In accordance with the invention, the headbox which is intended for high basis weights of over 400 g / m2 and for high fibre suspension consistencies in a range of 2–5% comprises an explosion chamber 4 for receiving the fibre suspension from the tube bank 2, which explosion chamber equalizes the transverse flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com