Patents

Literature

49results about How to "Maintain flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated filter media

InactiveUS20060231487A1Fine surfaceImprove abilitiesSemi-permeable membranesIsotope separationPolymer scienceFilter media

The invention relates to a coating composition on the surface of a filtration media. In particular, the invention relates to a coating composition for a filtration media comprising at least one polymer; at least one crosslinking agent; and optionally at least one compatabilizing agent.

Owner:THE LUBRIZOL CORP

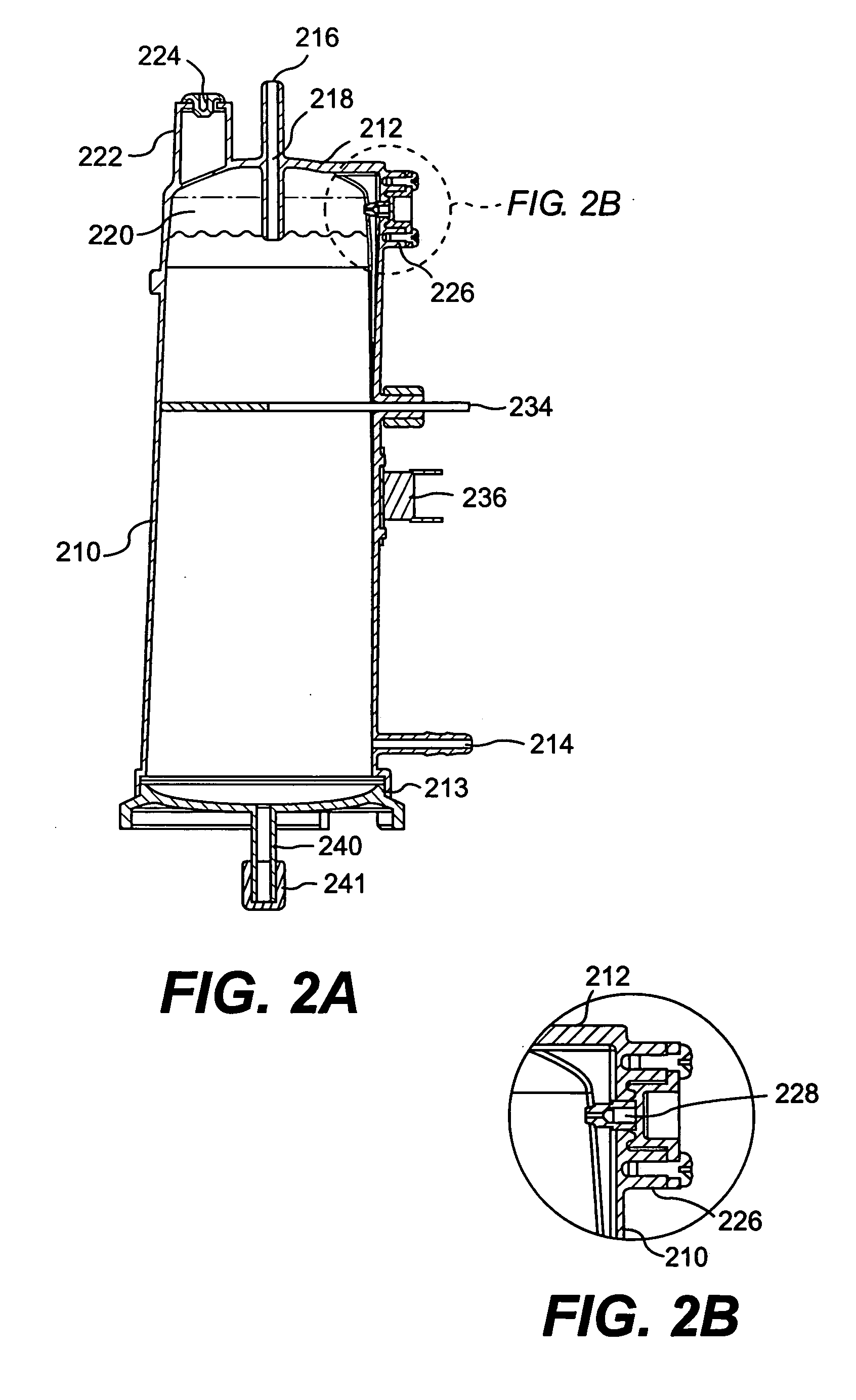

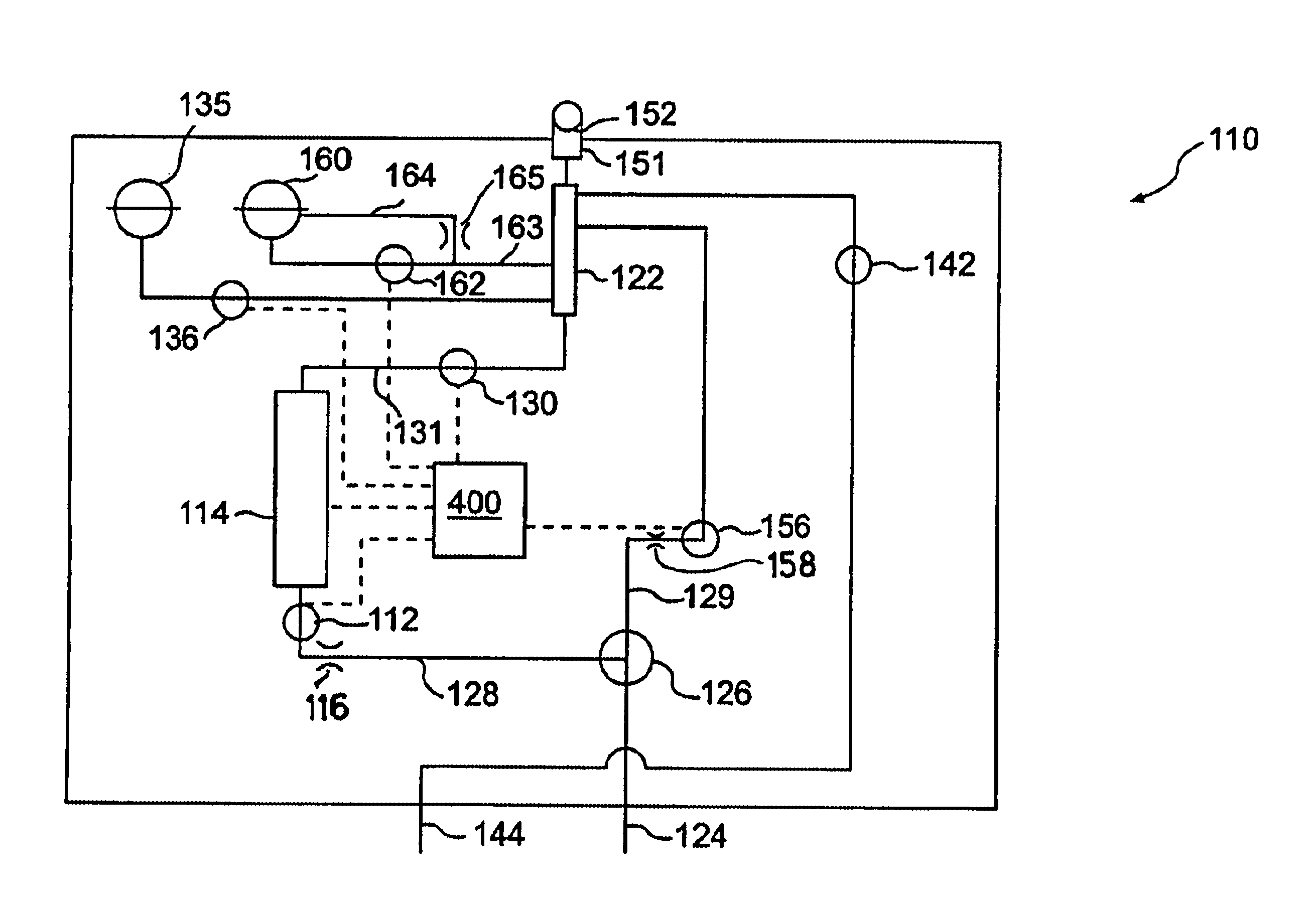

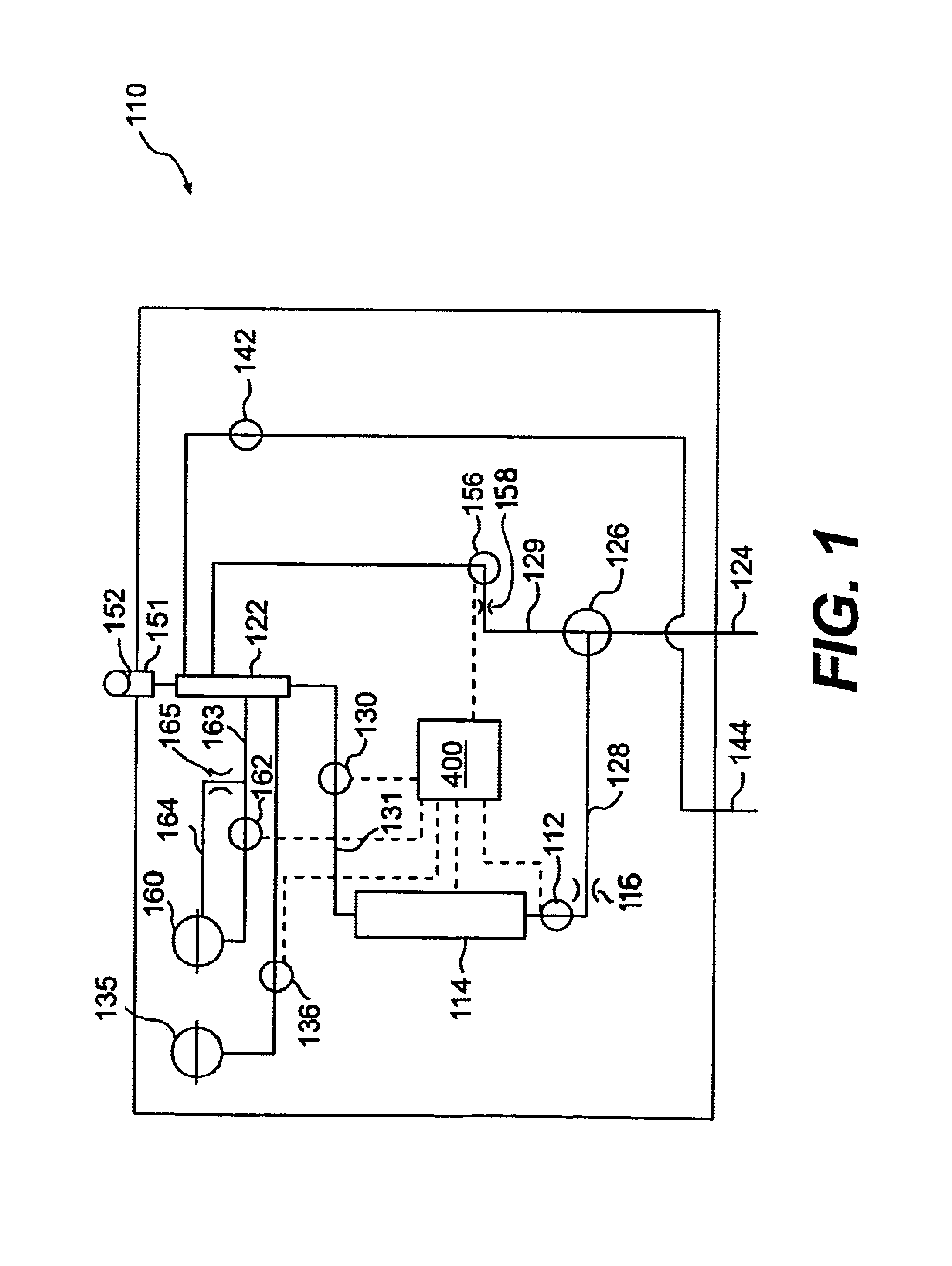

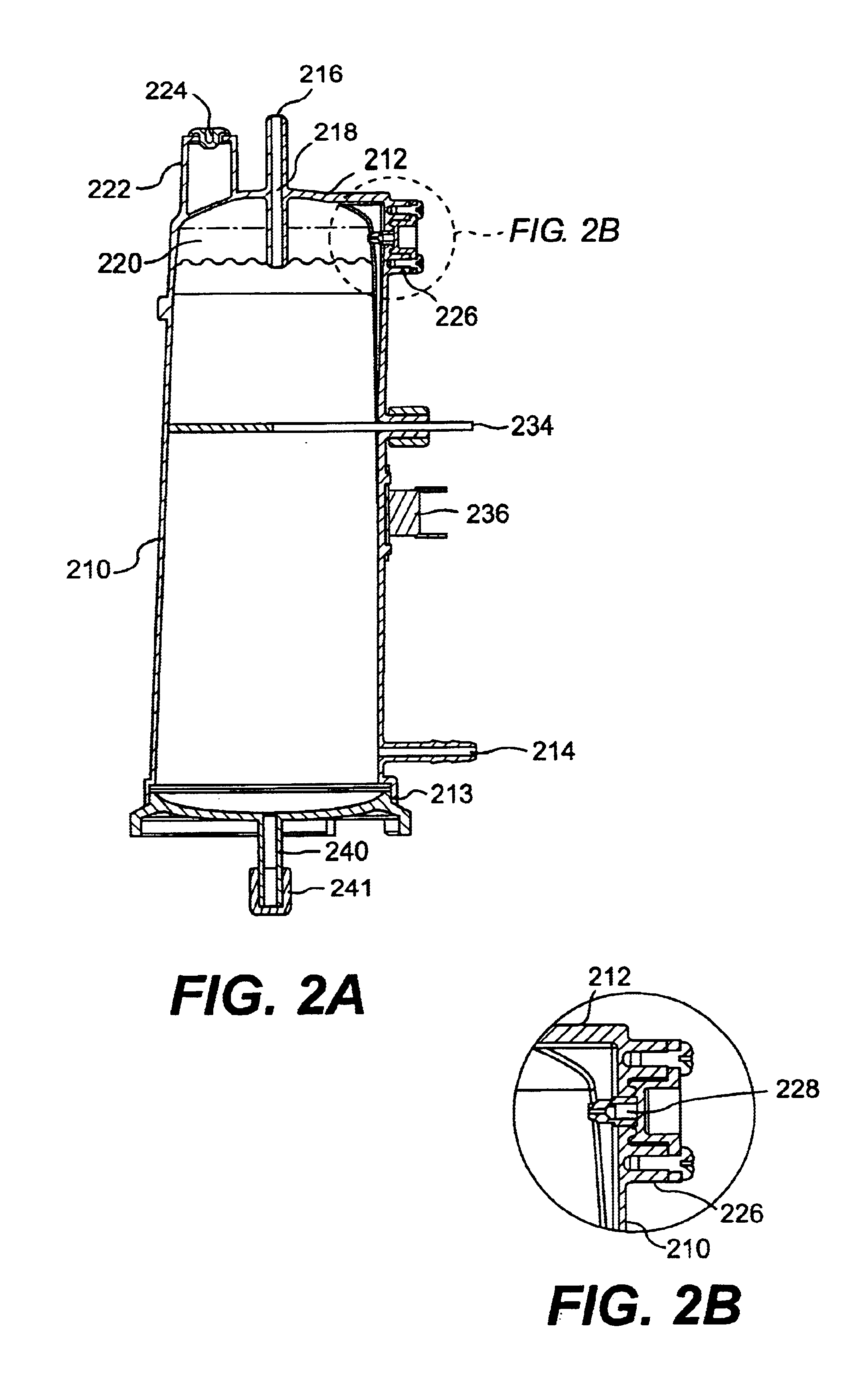

Brewed iced tea or non-carbonated drink dispenser

InactiveUS20050166766A1Efficient mixingHeating fastCooking vesselsBeverage vesselsEngineeringCarbonated drink

A beverage dispensing apparatus includes a mixing chamber for mixing hot water, a beverage concentrate and cold water, as well as one or more additives. The hot water and cold water are supplied at a predetermined flow rate at a predetermined proportion, regardless of the pressure of the water supply. A water heater supplies the hot water within a specified pressure range and without significant entrapped air.

Owner:JONES BRIAN C +4

Brewed iced tea or non-carbonated drink dispenser

ActiveUS20050166761A1Efficient mixingHeating fastLiquid transferring devicesBeverage vesselsEngineeringCarbonated drink

A beverage dispensing apparatus includes a mixing chamber for mixing hot water, a beverage concentrate and cold water, as well as one or more additives. The hot water and cold water are supplied at a predetermined flow rate at a predetermined proportion, regardless of the pressure of the water supply. A water heater supplies the hot water within a specified pressure range and without significant entrapped air.

Owner:PEPSICO INC

Brewed iced tea or non-carbonated drink dispenser

InactiveUS6915732B2Heating fastSignificant variation of flow rateLiquid transferring devicesBeverage vesselsAir entrainmentEngineering

A beverage dispensing apparatus includes a mixing chamber for mixing hot water, a beverage concentrate and cold water, as well as one or more additives. The hot water and cold water are supplied at a predetermined flow rate at a predetermined proportion, regardless of the pressure of the water supply. A water heater supplies the hot water within a specified pressure range and without significant entrapped air.

Owner:PEPSICO INC

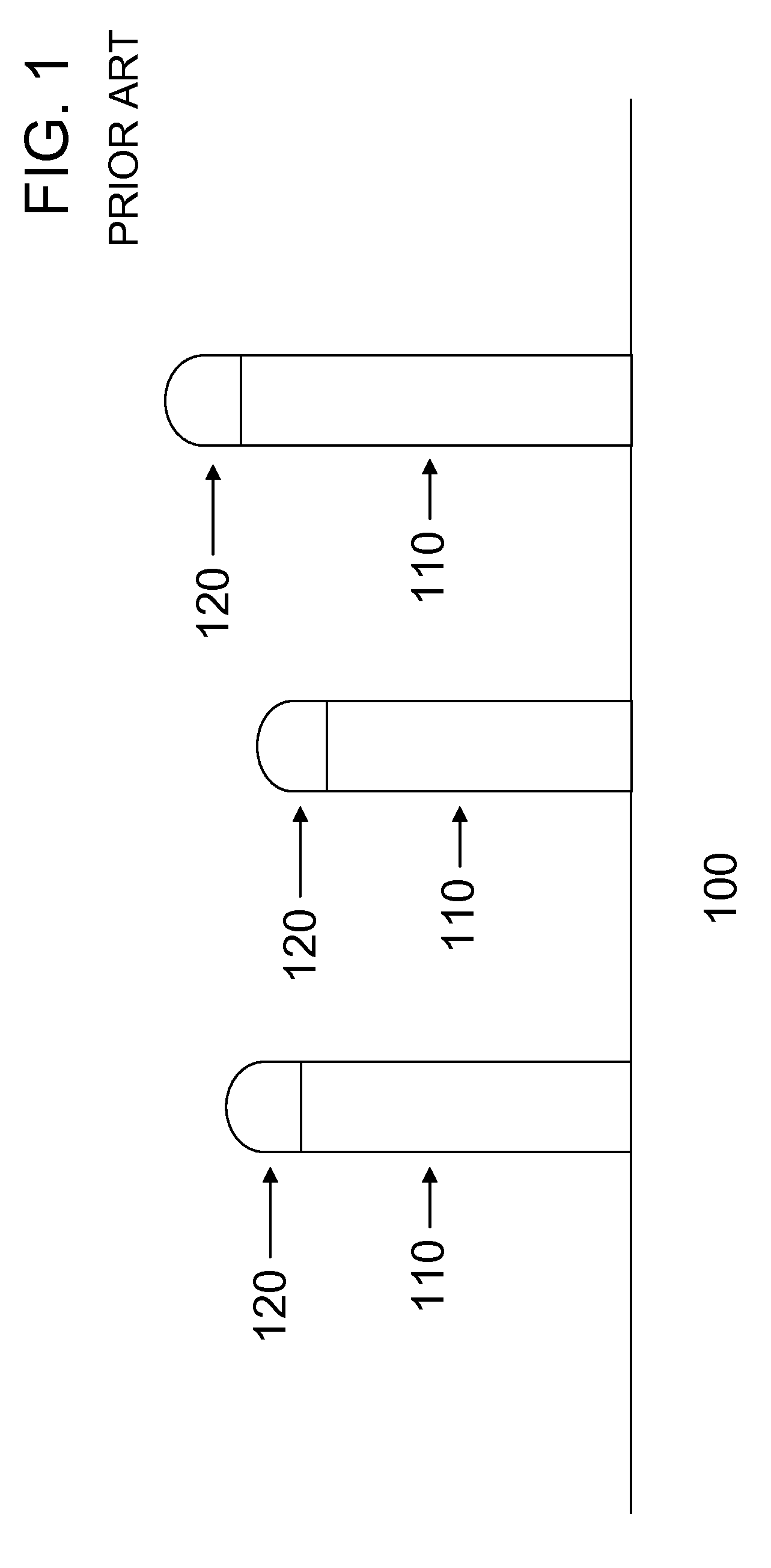

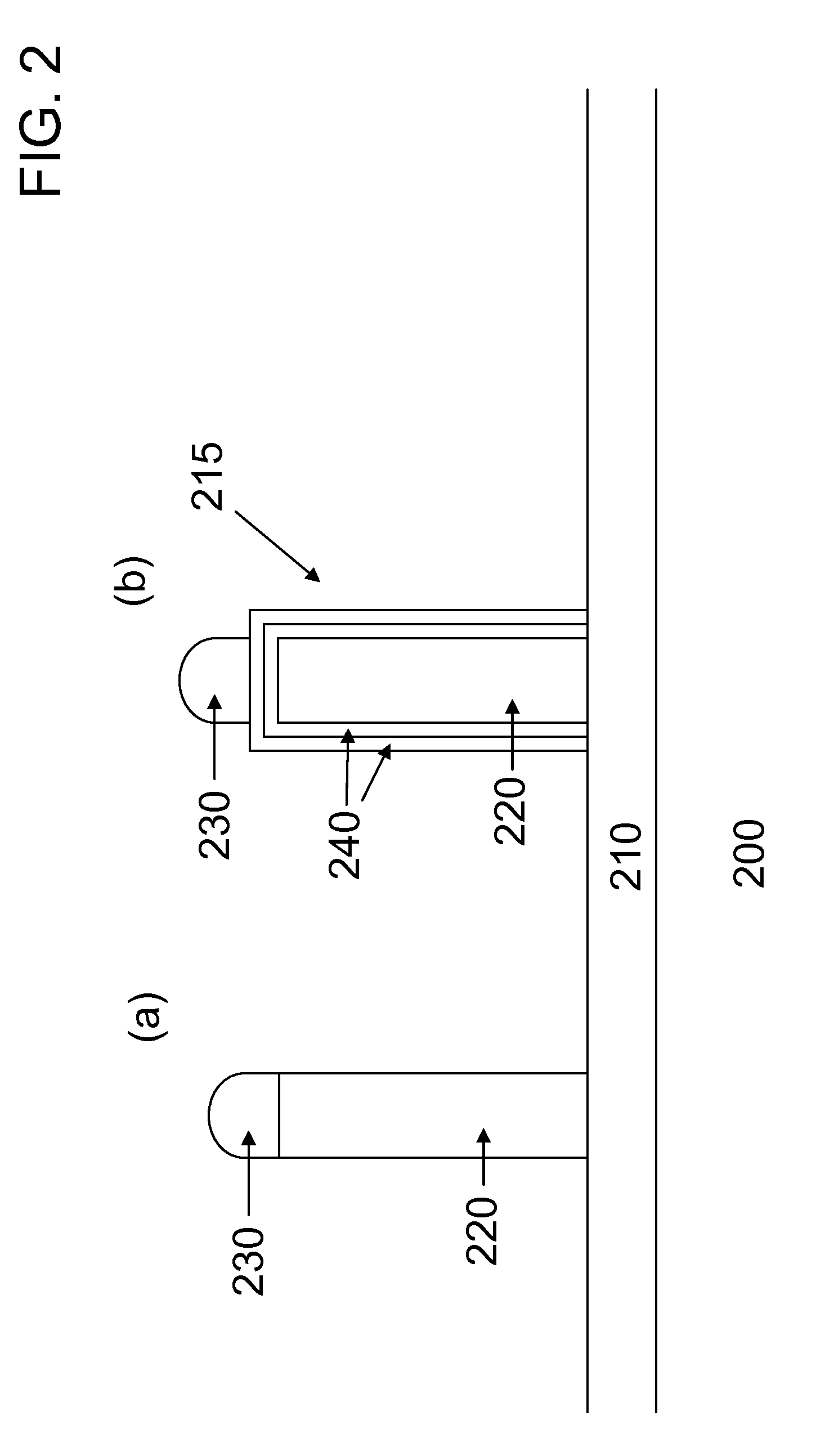

Forming ii-vi core-shell semiconductor nanowires

InactiveUS20110177683A1Many solutionsLow melting pointNanoinformaticsSemiconductor/solid-state device manufacturingNanowireNanoparticle

A method of making II-VI core-shell semiconductor nanowires includes providing a support; depositing a layer including metal alloy nanoparticles on the support; and heating the support and growing II-VI core semiconductor nanowires where the metal alloy nanoparticles act as catalysts and selectively cause localized growth of the core nanowires. The method further includes modifying the growth conditions and shelling the core nanowires to form II-VI core-shell semiconductor nanowires.

Owner:NANOCO TECH LTD

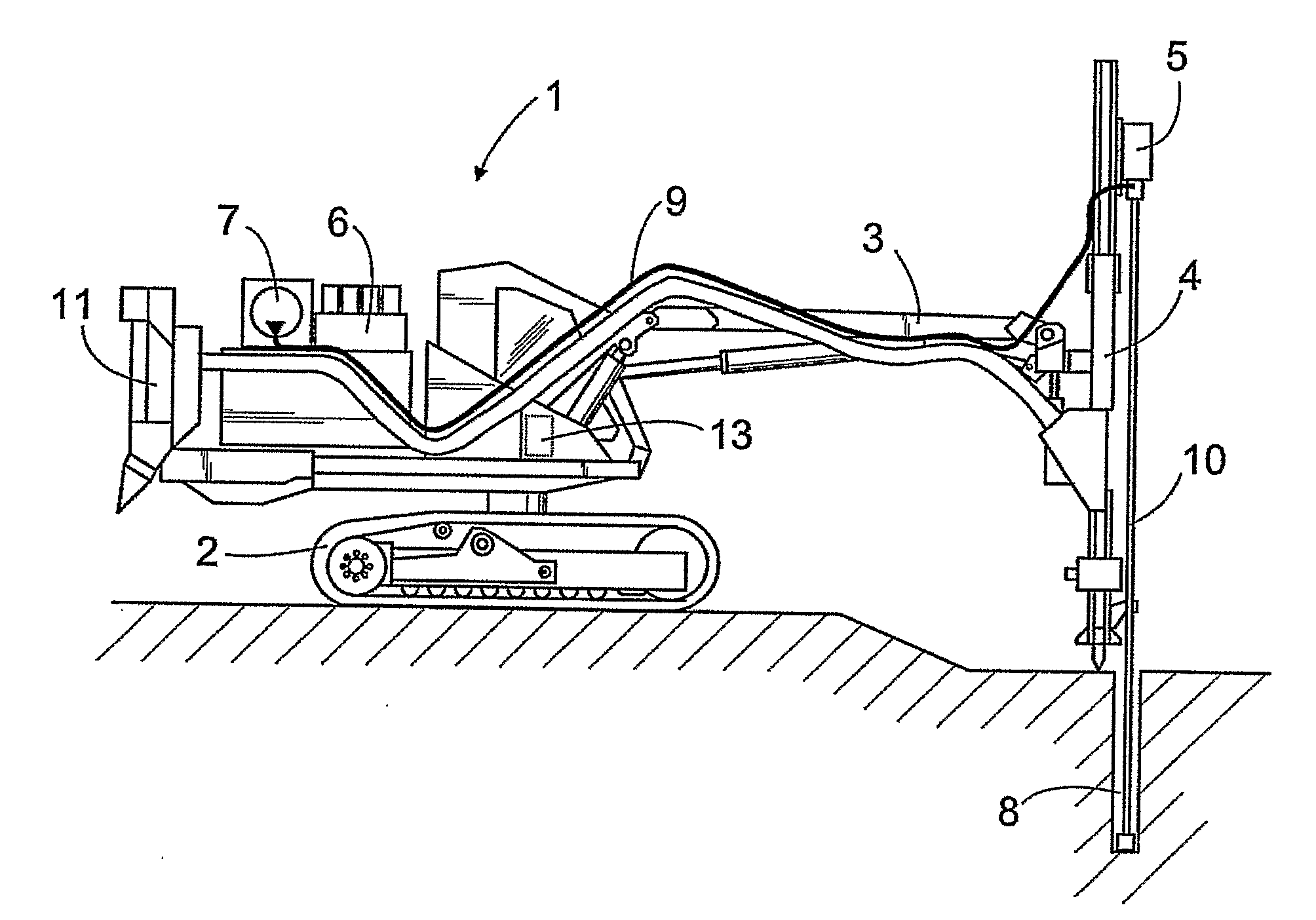

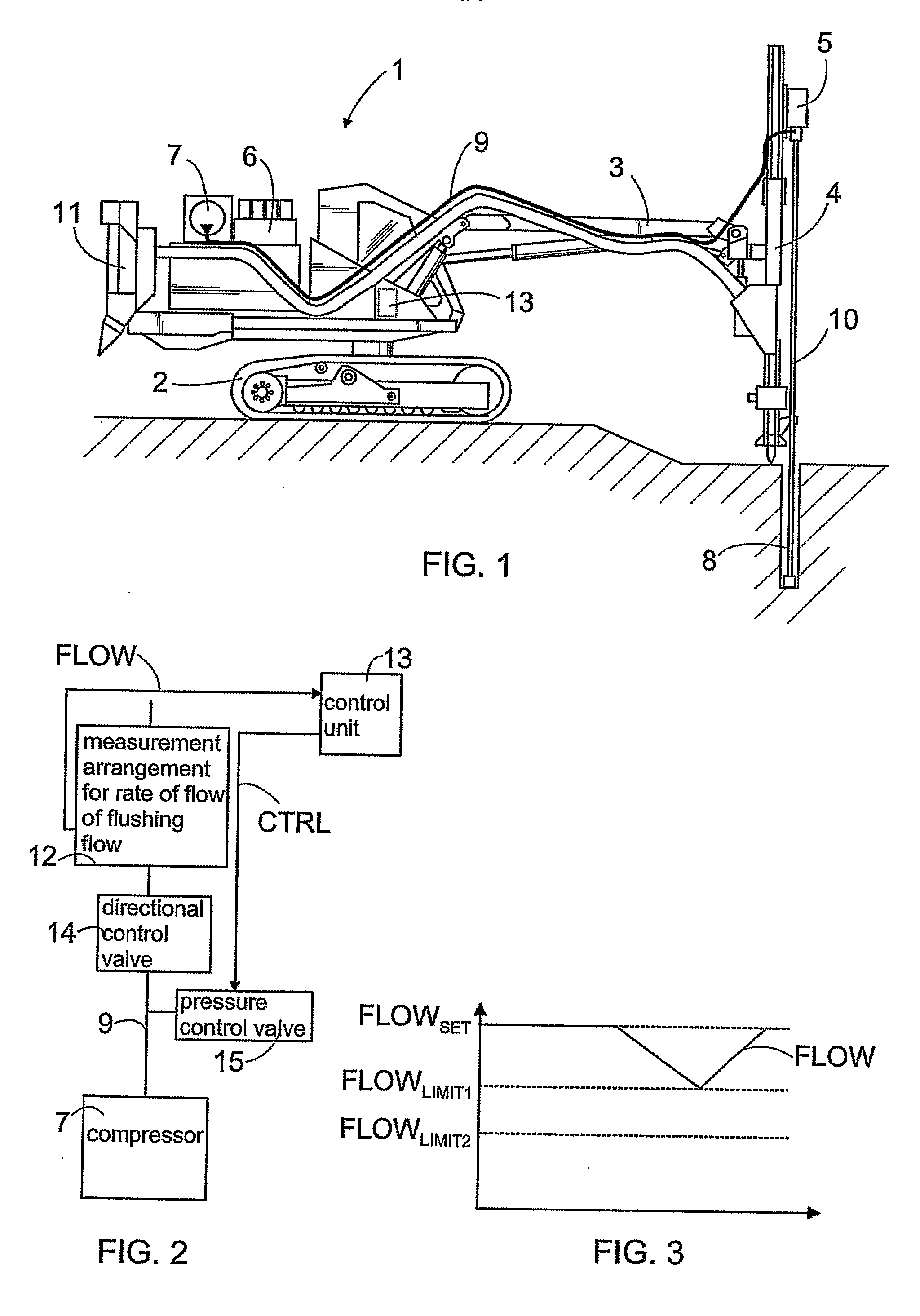

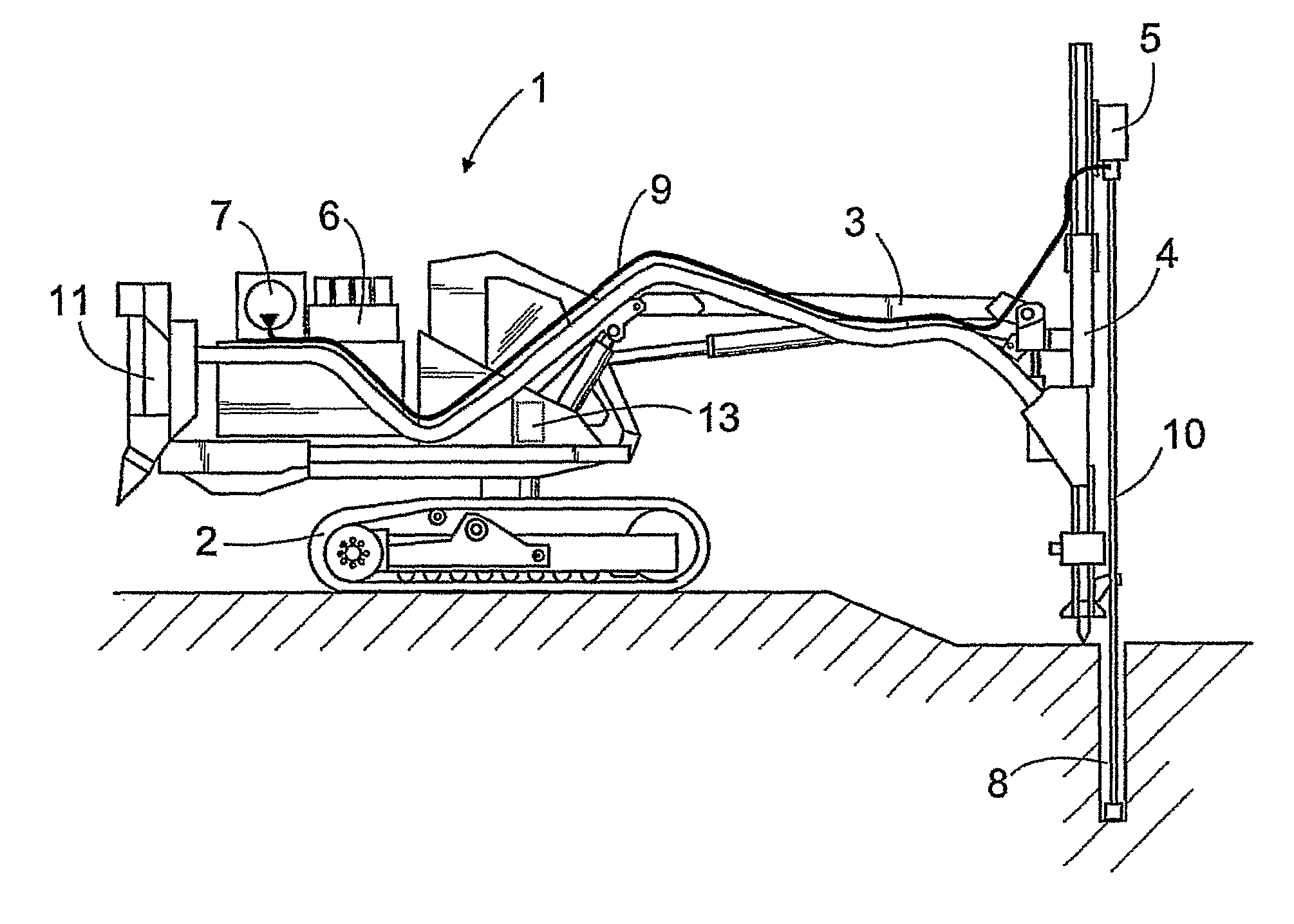

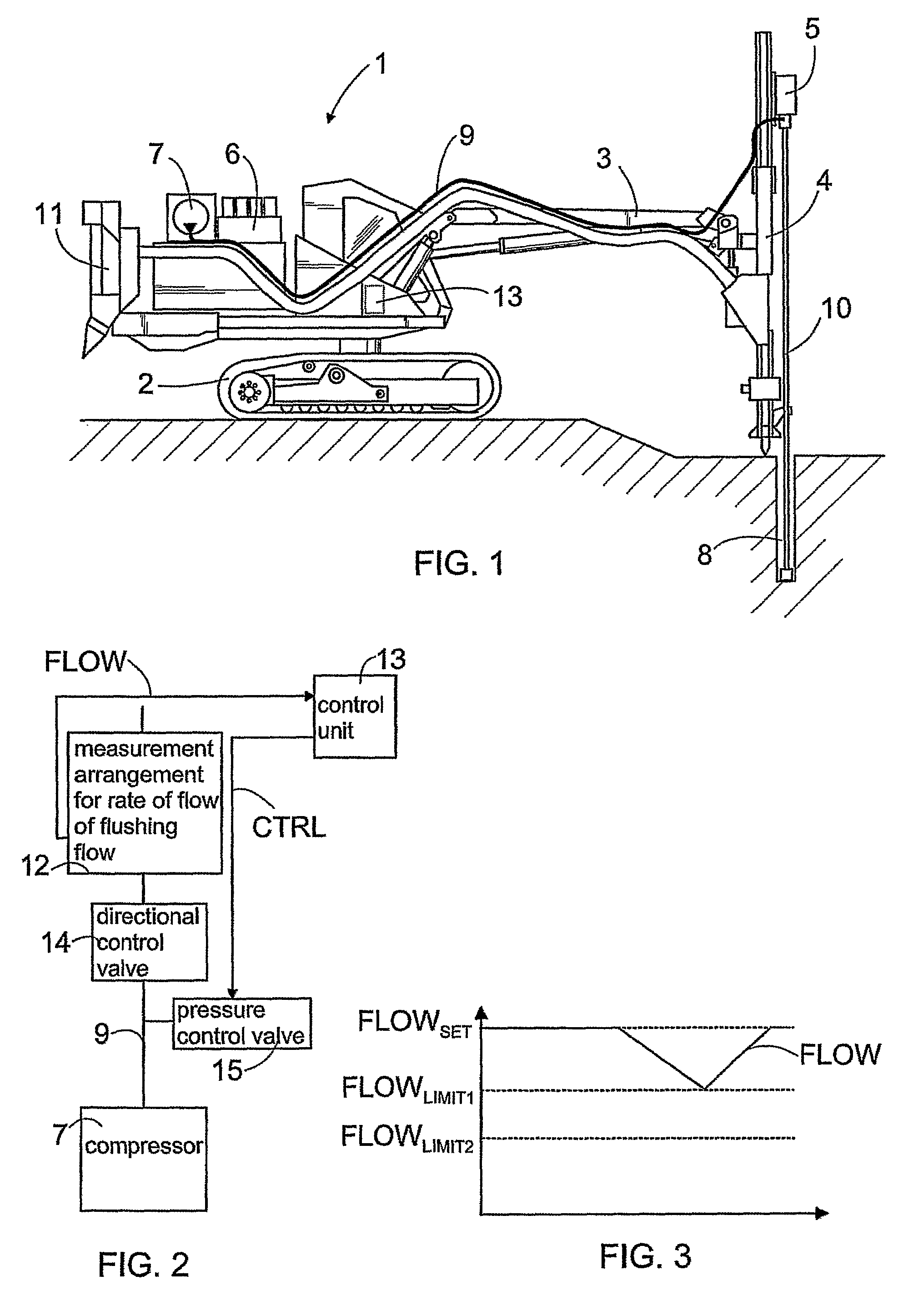

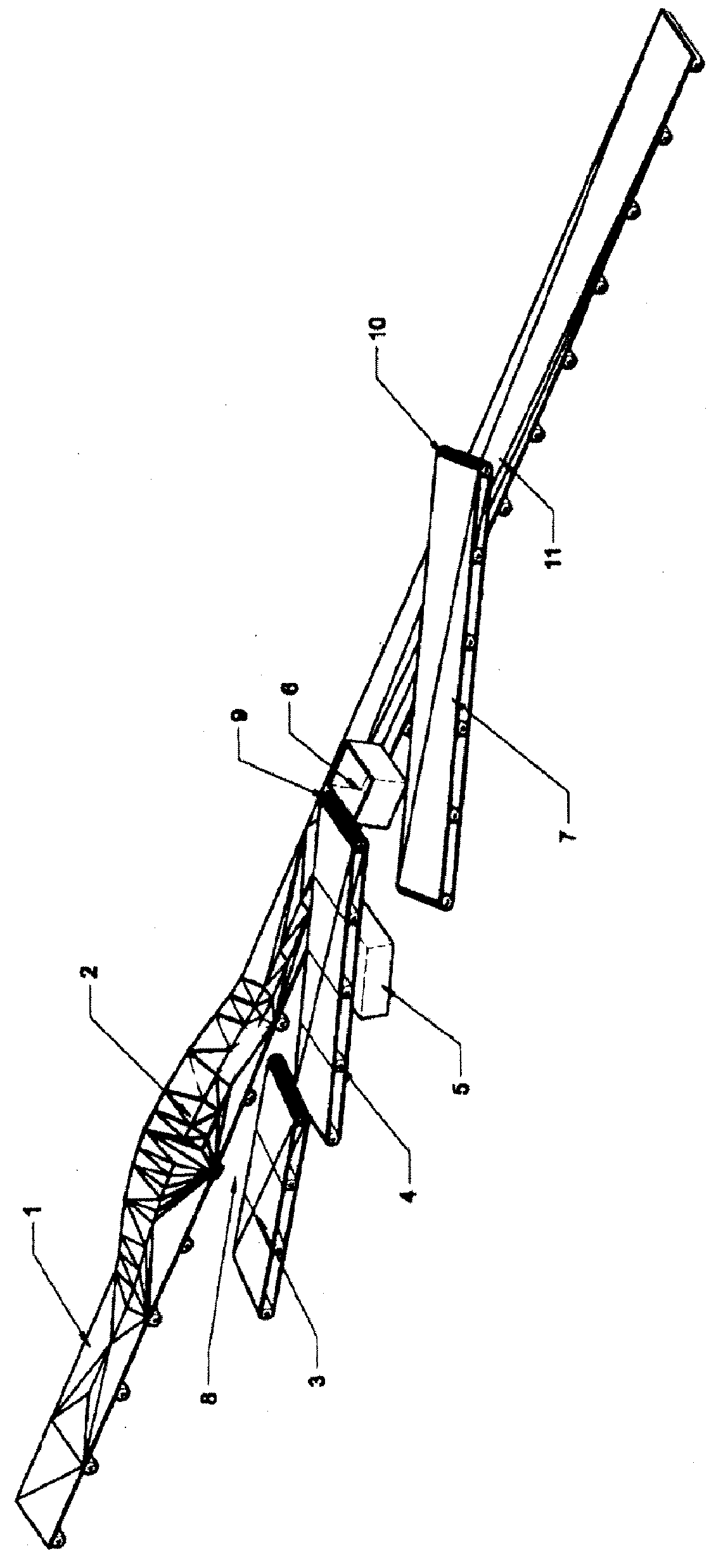

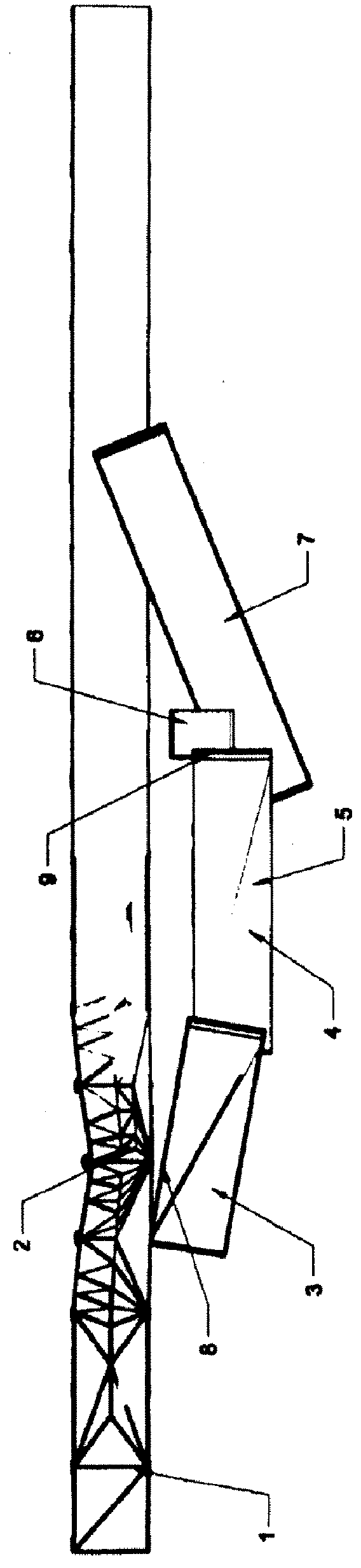

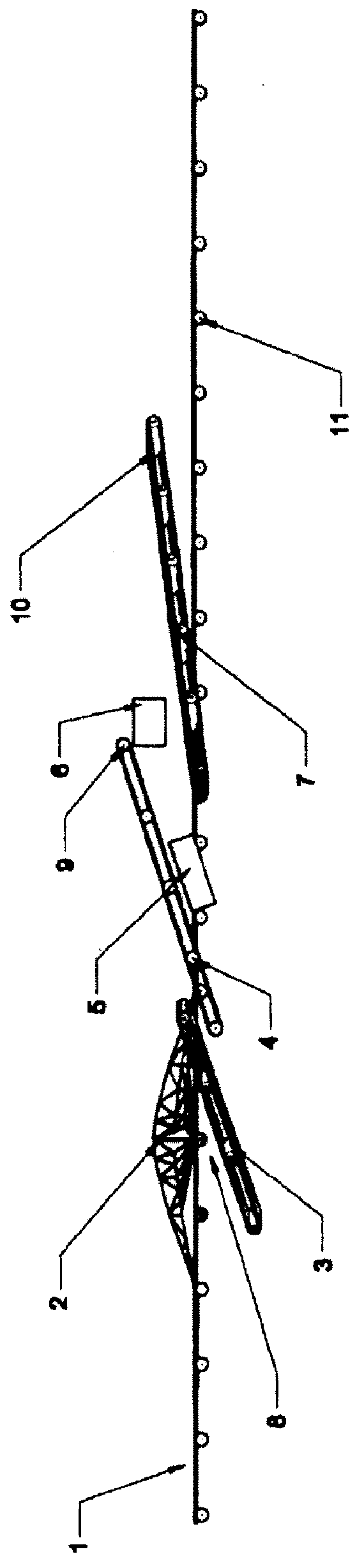

Method of controlling operation of rock drilling rig, and rock drilling rig

Owner:SANDVIK MINING & CONSTR OY

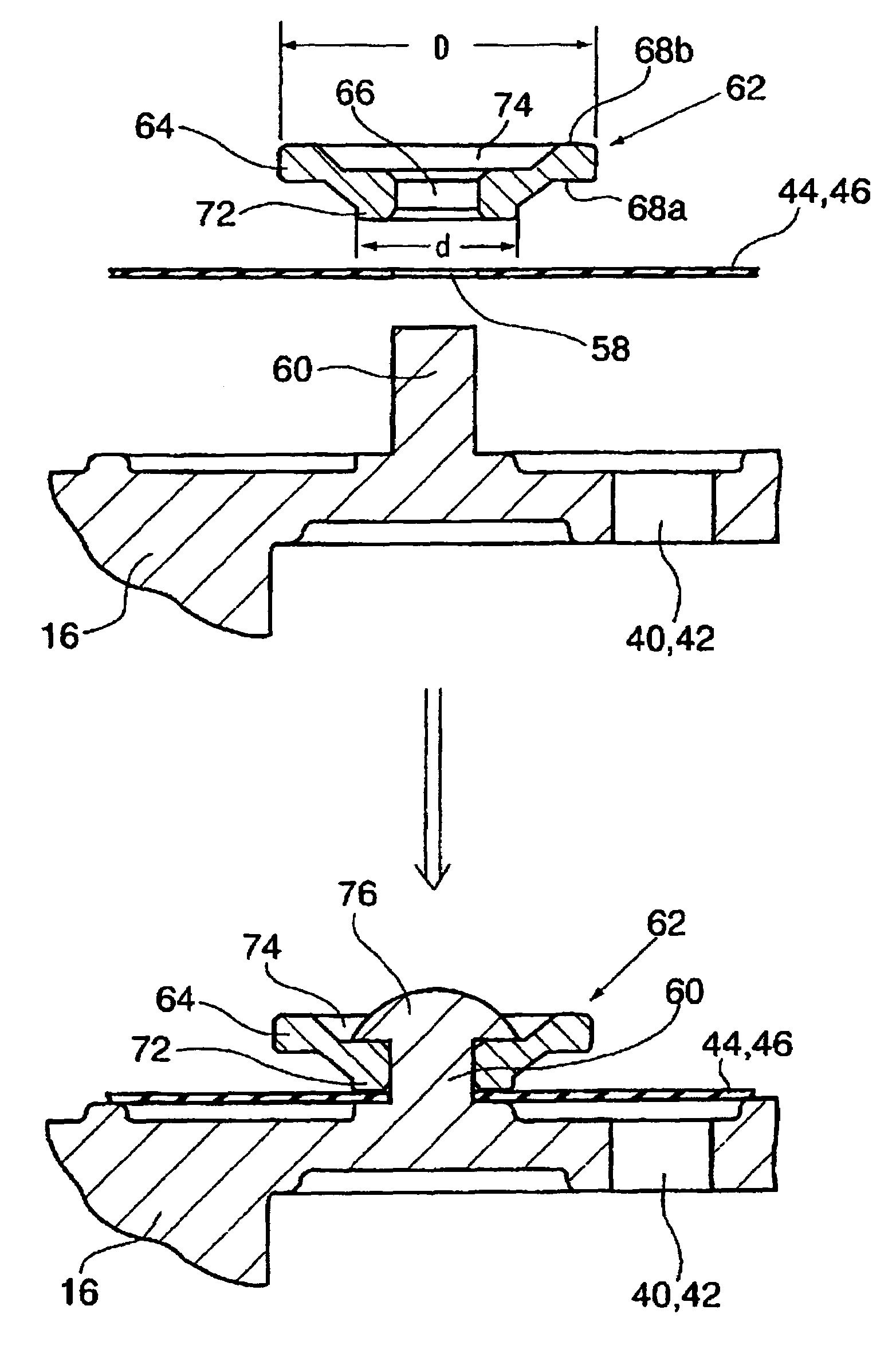

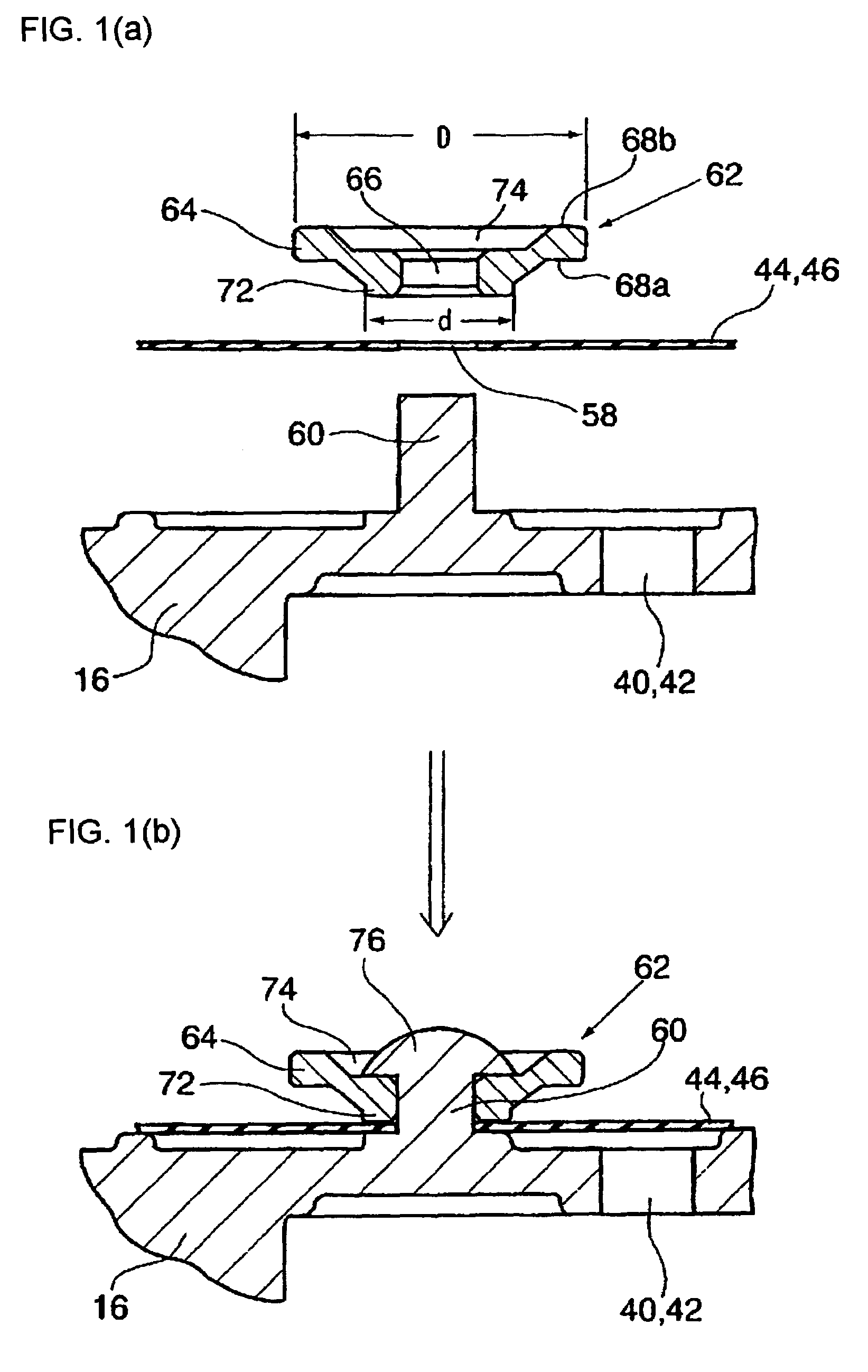

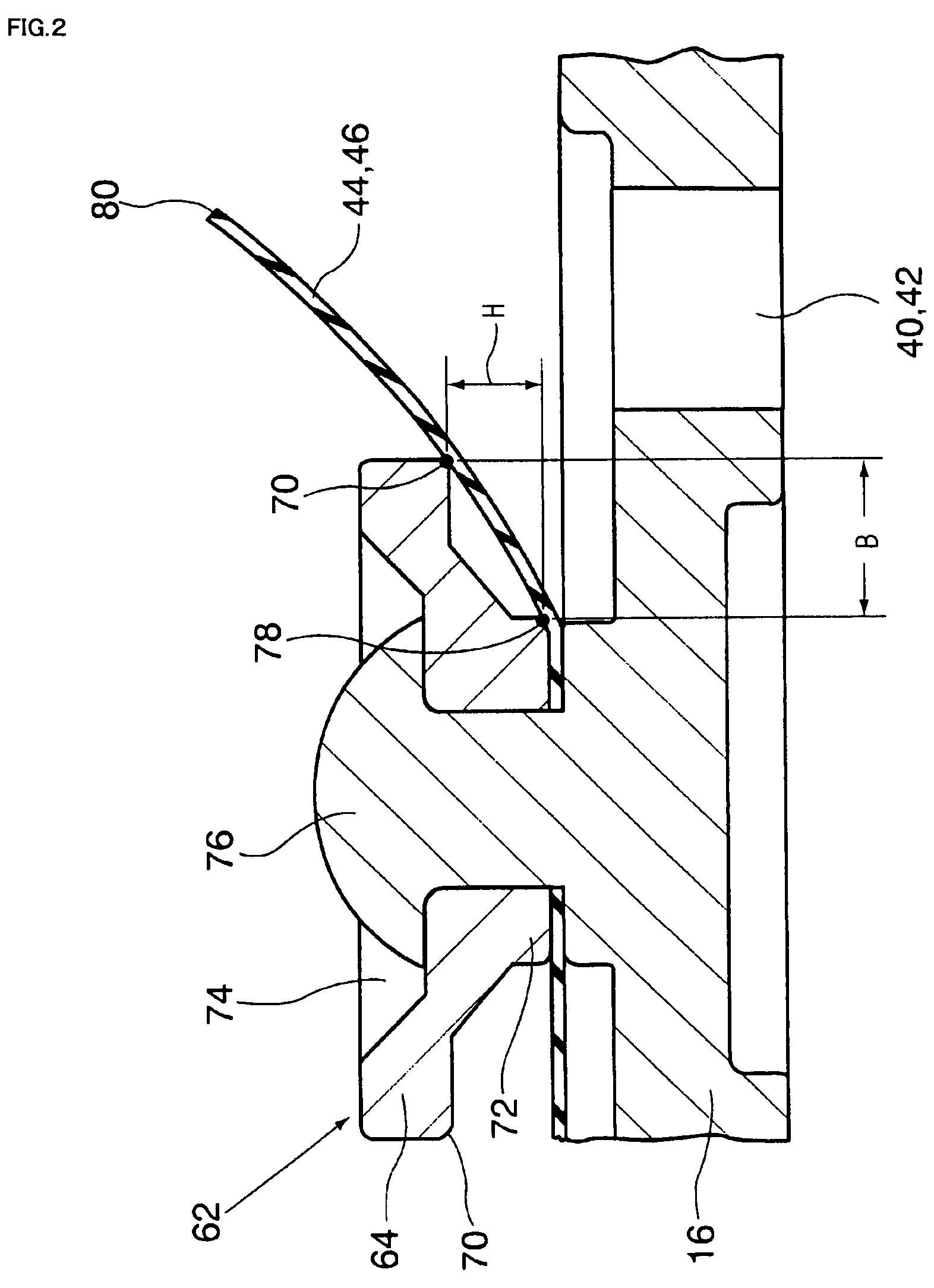

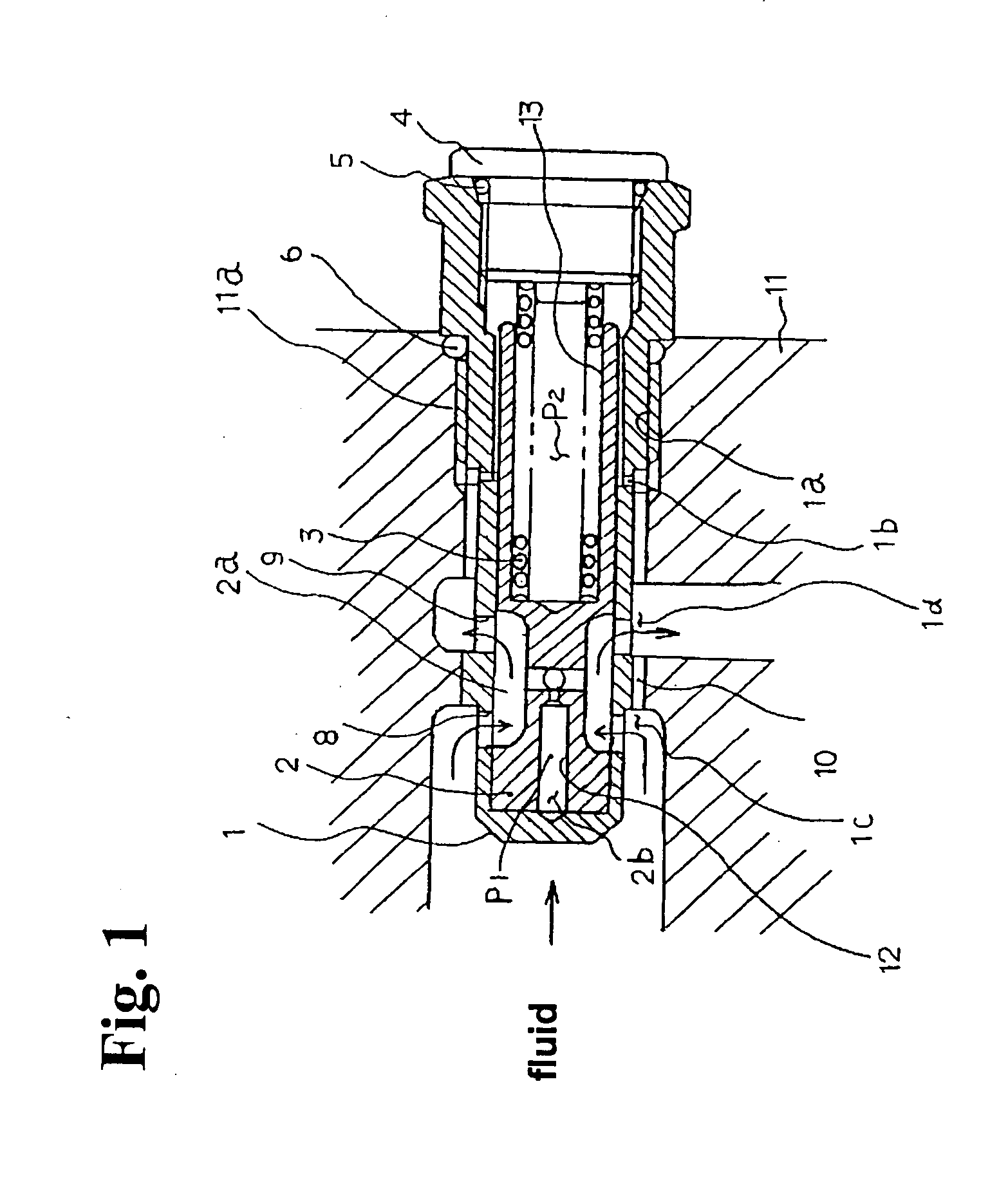

Valve apparatus

ActiveUS7311119B2Small priceValve lift amount (valve opening) can be restrictedPositive displacement pump componentsCheck valvesEngineeringCheck valve

A valve apparatus is small, and regulates a fuel amount by restricting a lift amount of a valve. A columnar portion is formed on a pump body. The columnar portion is inserted into a check valve and a washer formed with a protruding portion which protrudes outward from a flange portion, and the check valve and washer are attached or fixed to the pump body by subjecting a tip end of the columnar portion to thermal caulking or the like. An outer diameter of the protruding portion is set to be relatively smaller than an outer diameter of the flange portion such that when the check valve is sandwiched between the protruding portion and pump body, the check valve contacts an outer peripheral edge of the flange portion when the check valve opens. As a result, a lift amount of the valve can be restricted, and a flow rate of fuel passing through a passage can be maintained at a constant level.

Owner:MIKUNI CORP

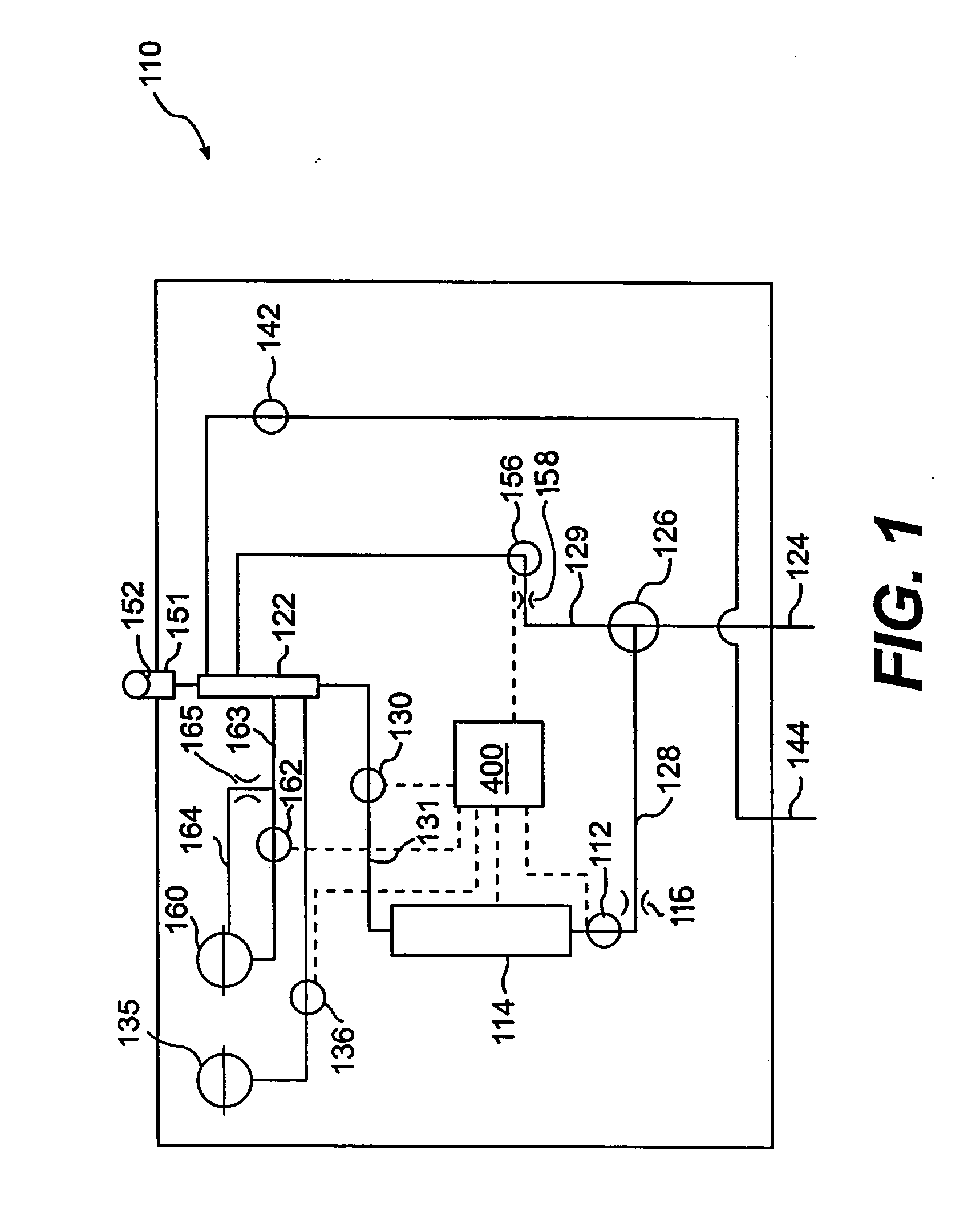

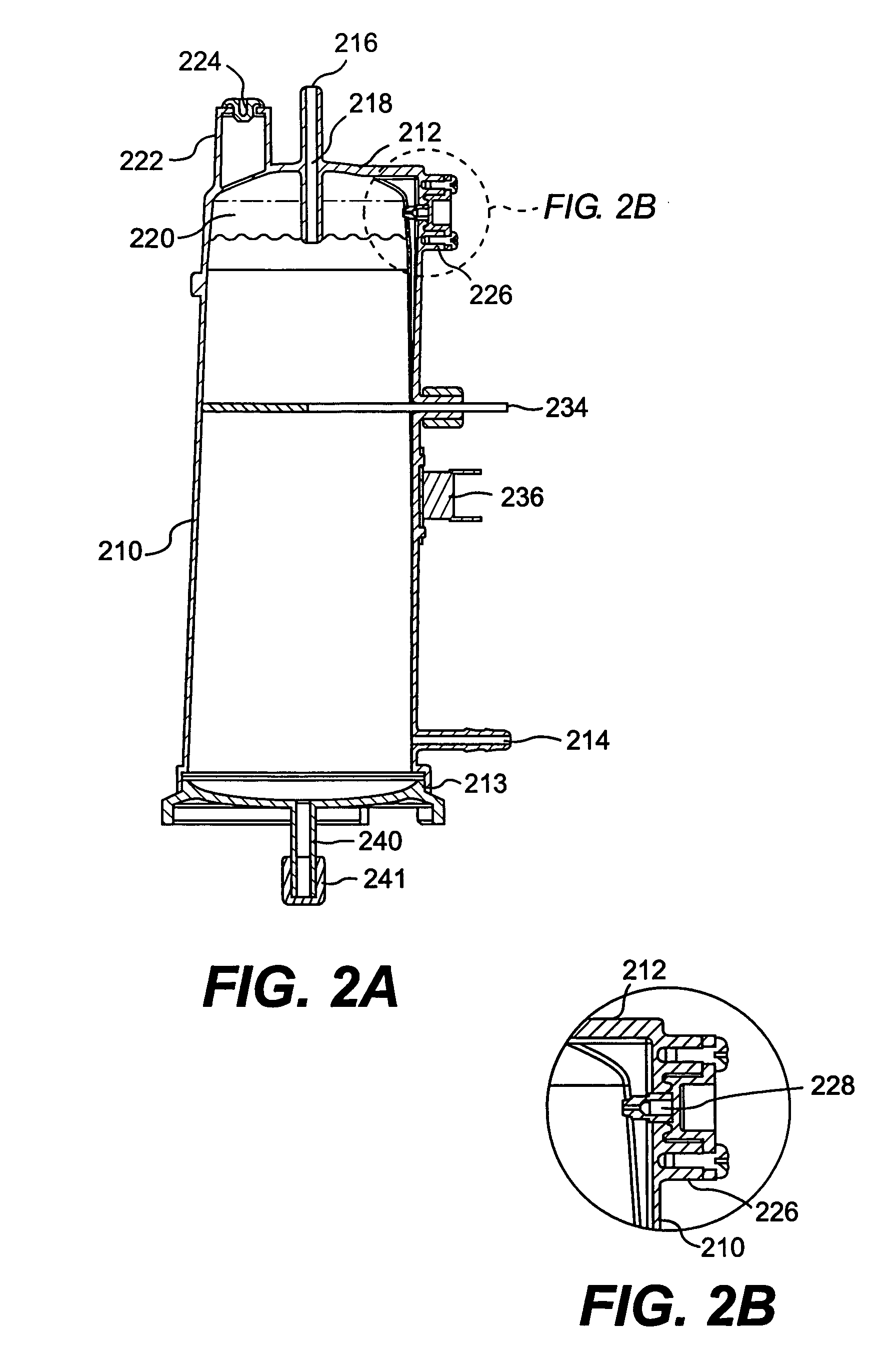

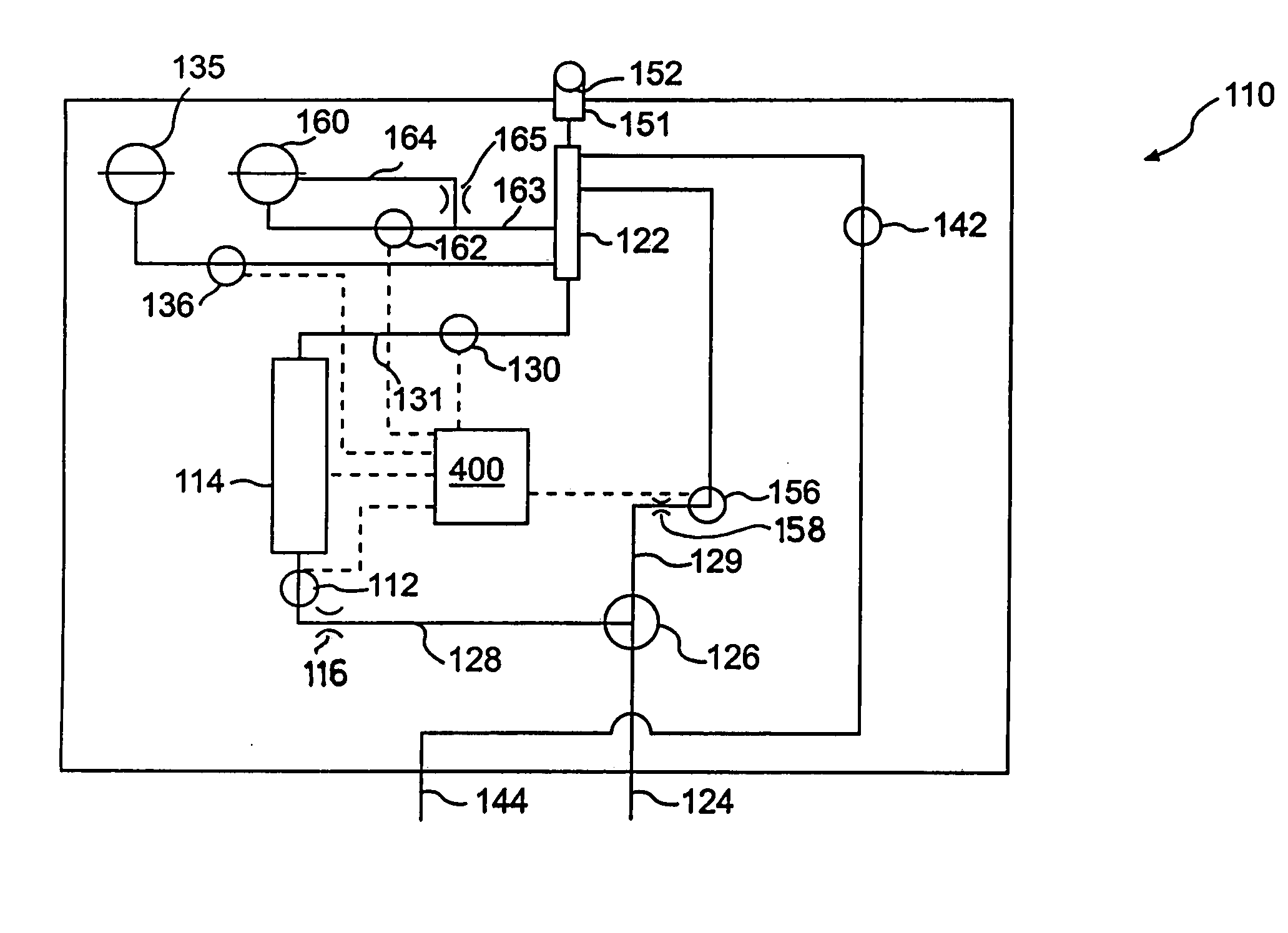

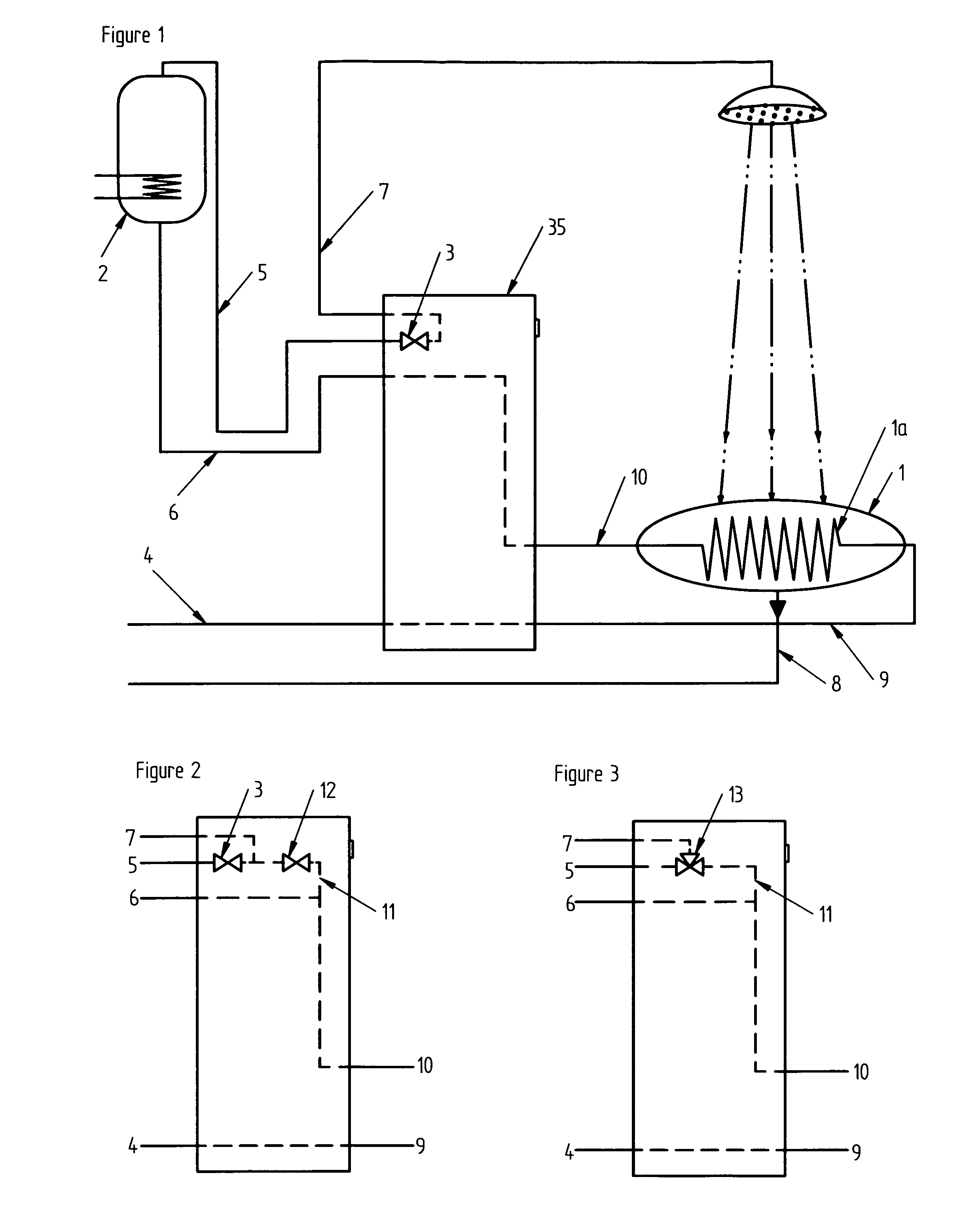

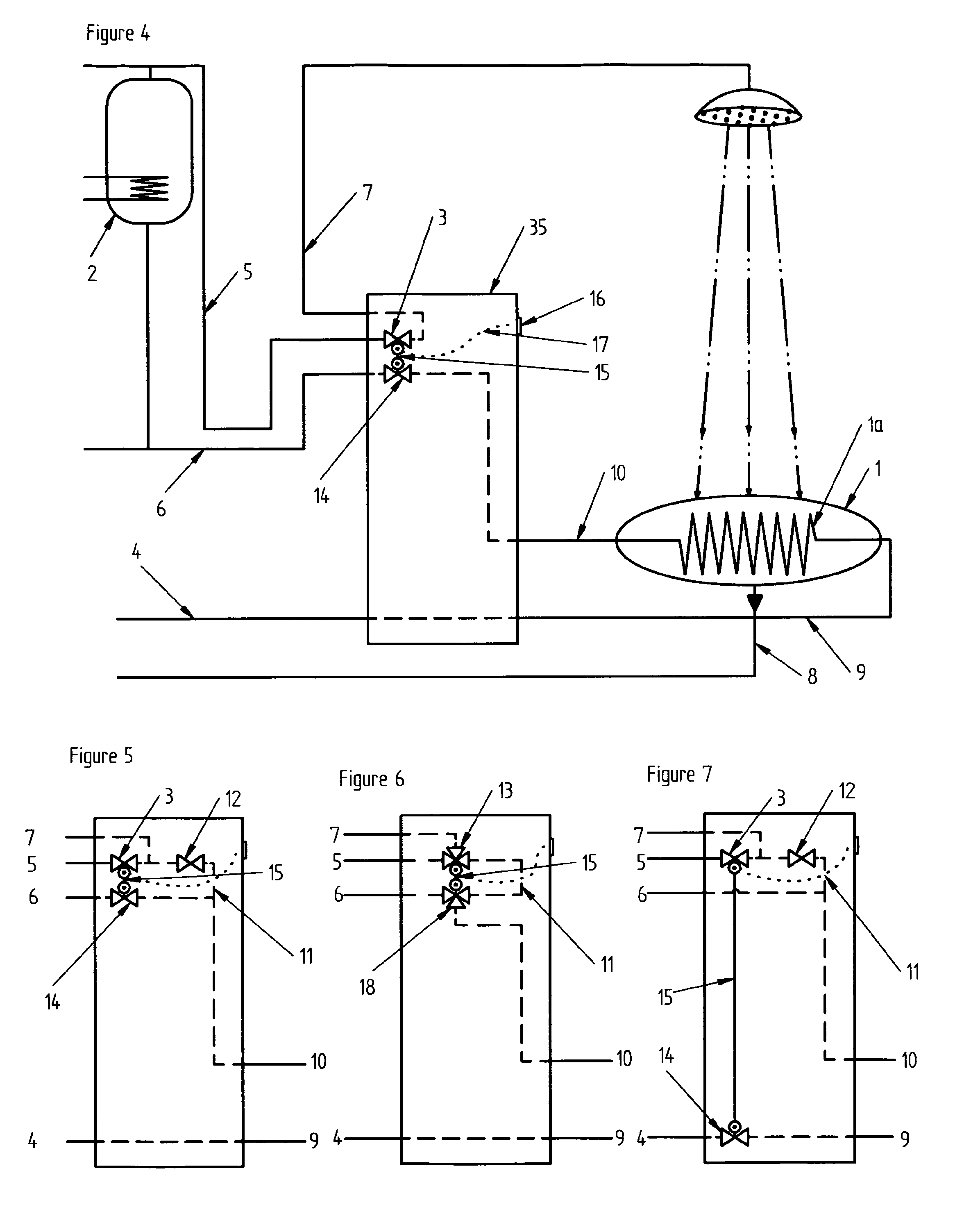

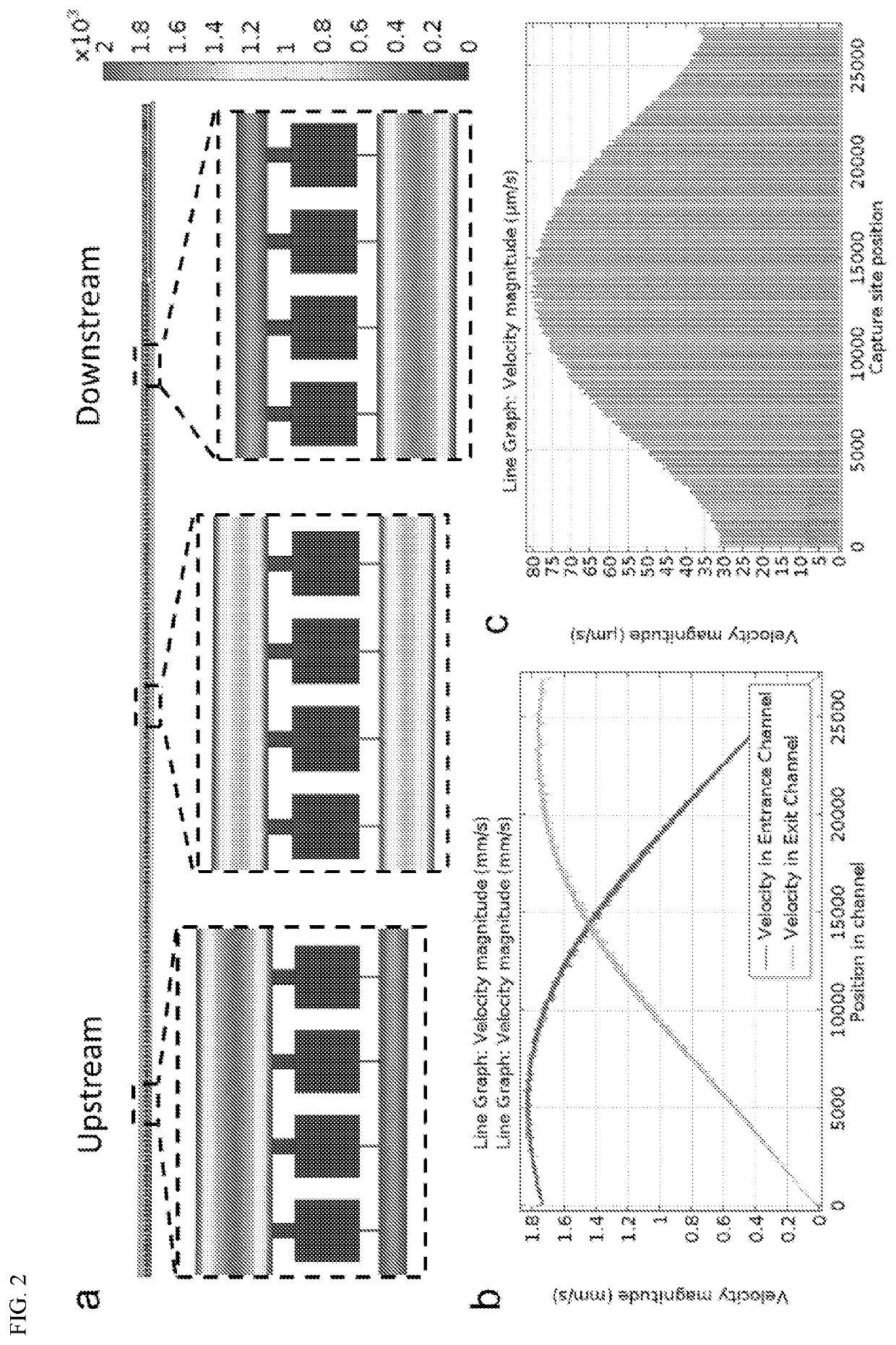

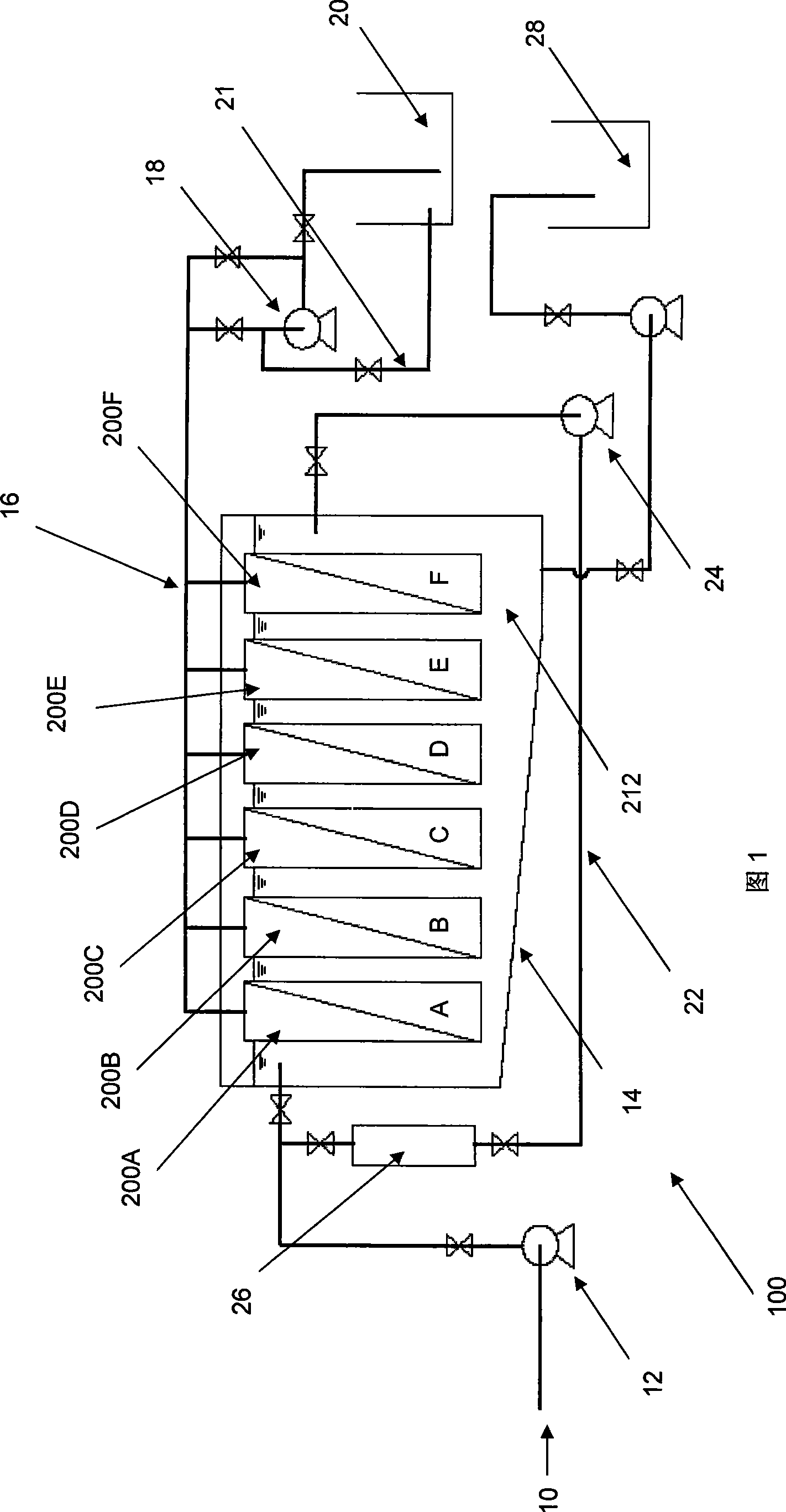

Fluid Flow Control System

ActiveUS20130199627A1Maintain flow rateEasy temperature controlLighting and heating apparatusPipe heating/coolingControl systemEngineering

A fluid flow control system has a heating device for heating a fluid and a first flow path for providing the heated fluid from the heating device to a use region. A heat exchanger has a supply path that received fluid from a fluid supply, and an outlet path that receives fluid from the use region, whereby the fluid in the supply path is pre-heated by the fluid in the outlet path. A second flow path provides pre-heated fluid from the supply path of the heat exchanger to the heating device. Modulating devices control fluid flow through the outlet path along the supply path. A flow control device controls the modulating devices such that the fluid flow rates in the fluid supply path and outlet path of the heat exchanger are balanced, so as to be substantially the same.

Owner:PATRICK GILBERT

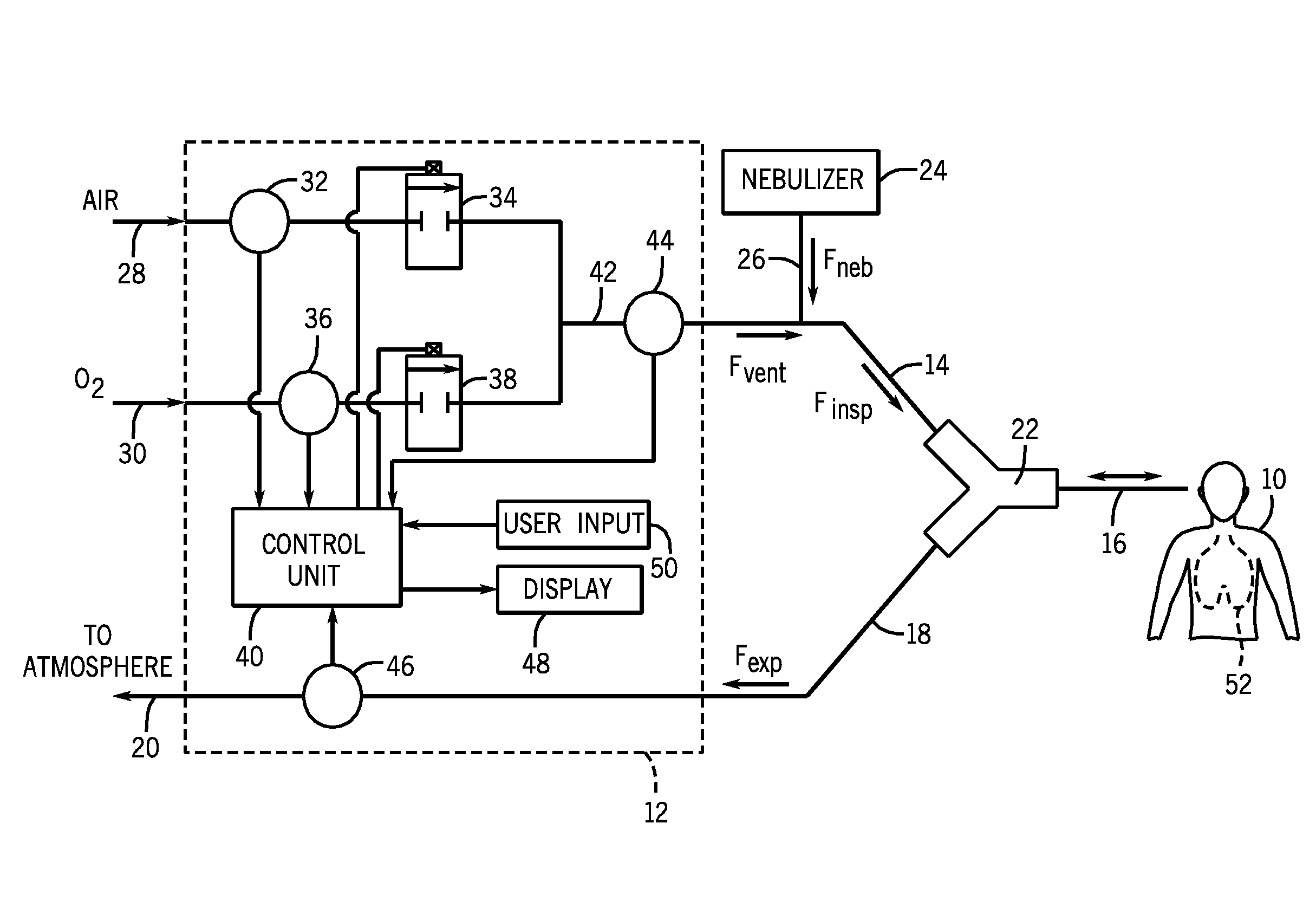

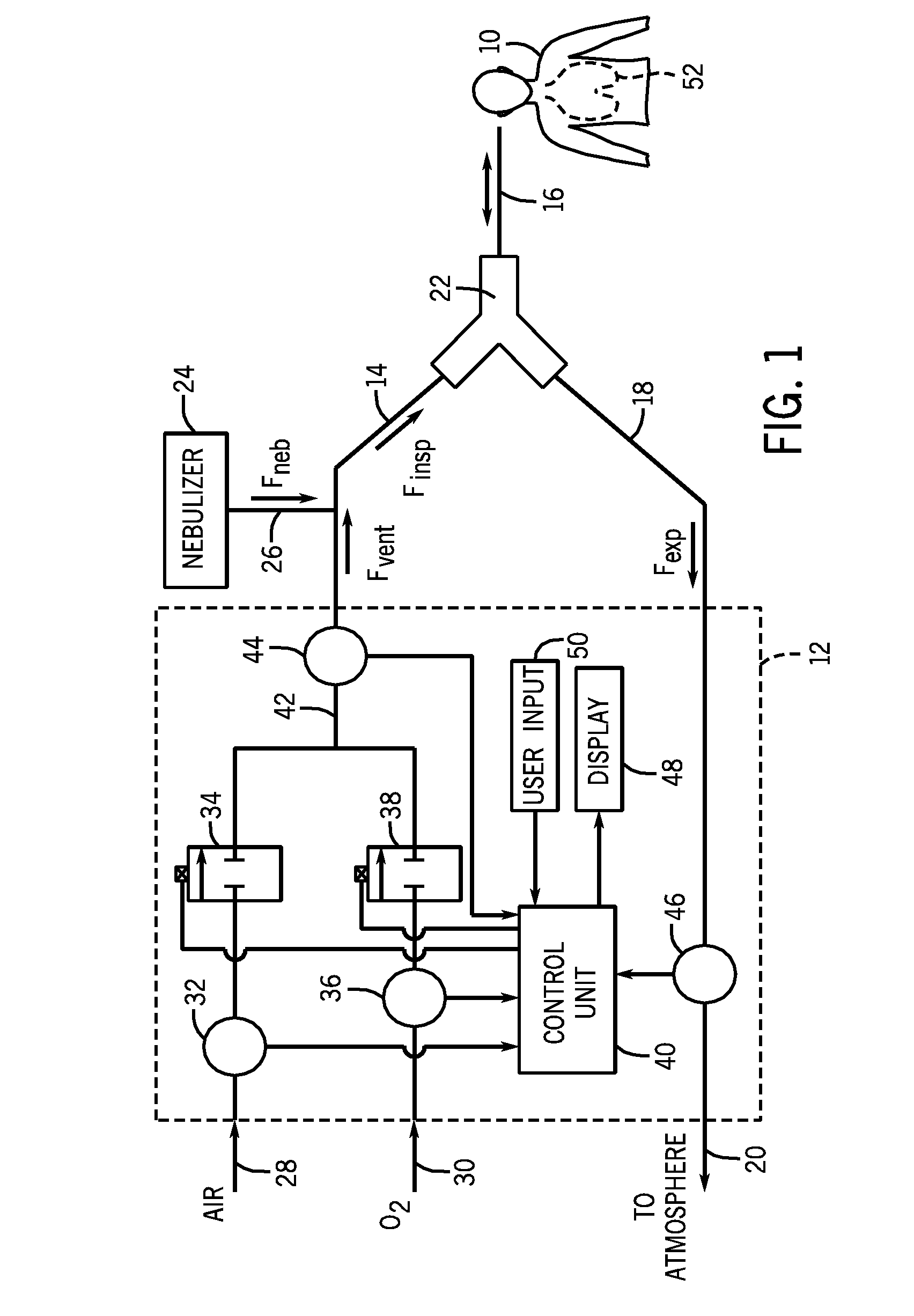

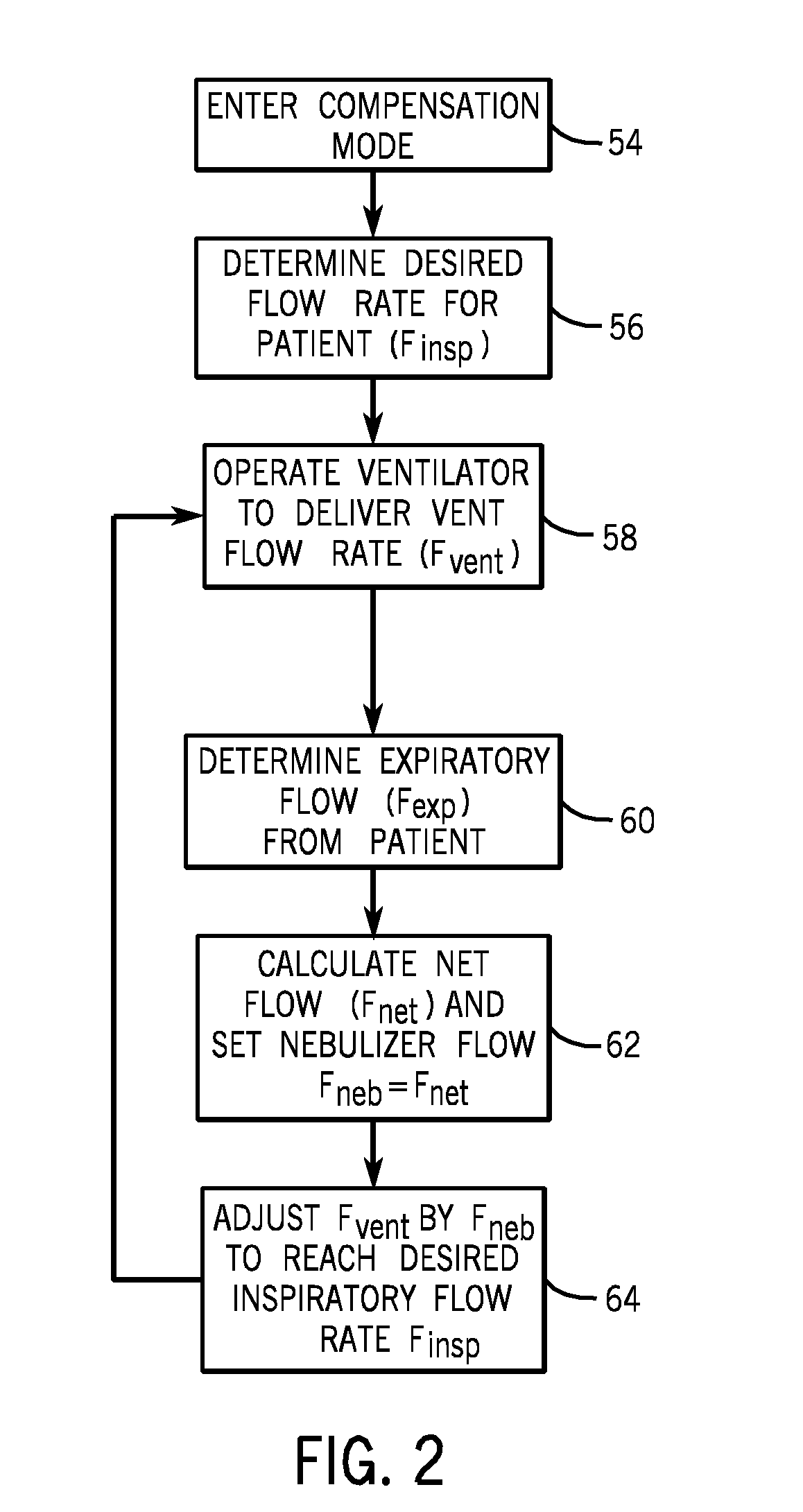

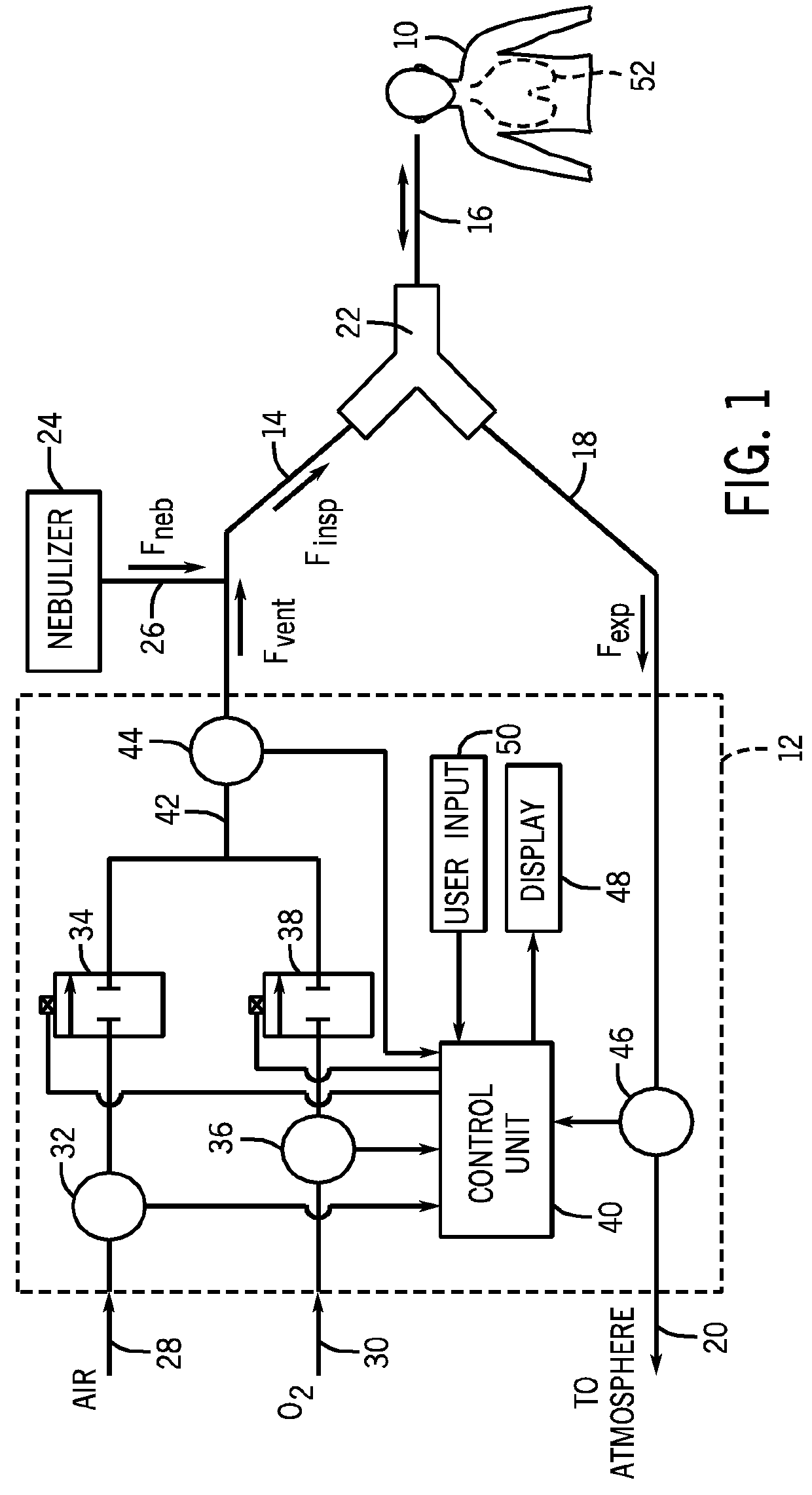

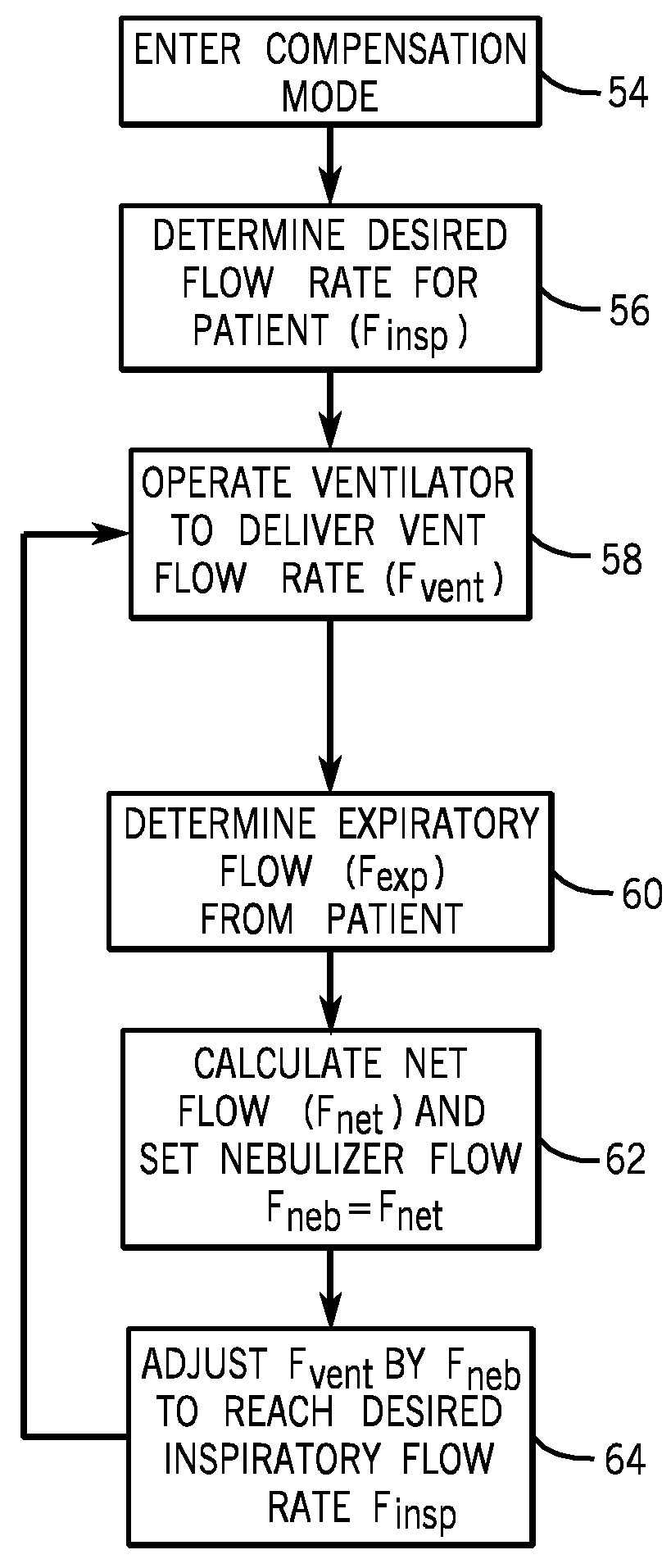

Compensation for unmeasurable inspiratory flow in a critical care ventilator

InactiveUS20110180063A1Reduce flow rateReduce trafficRespiratorsOperating means/releasing devices for valvesNebulizerInspiratory flow

A system and method for operating a ventilator to compensate for external gas flow reaching a patient from an external device, such as a nebulizer. A control unit of the ventilator monitors the gas flow rate from the ventilator and compares the gas flow rate from the ventilator to an expired gas flow rate from the patient. The difference between the inspired flow rate and the expired flow rate is due to the external device. The control unit modifies the operation of the ventilator to compensate for the external gas flow rate such that the flow of gas reaching the patient is maintained at a desired level.

Owner:GENERAL ELECTRIC CO

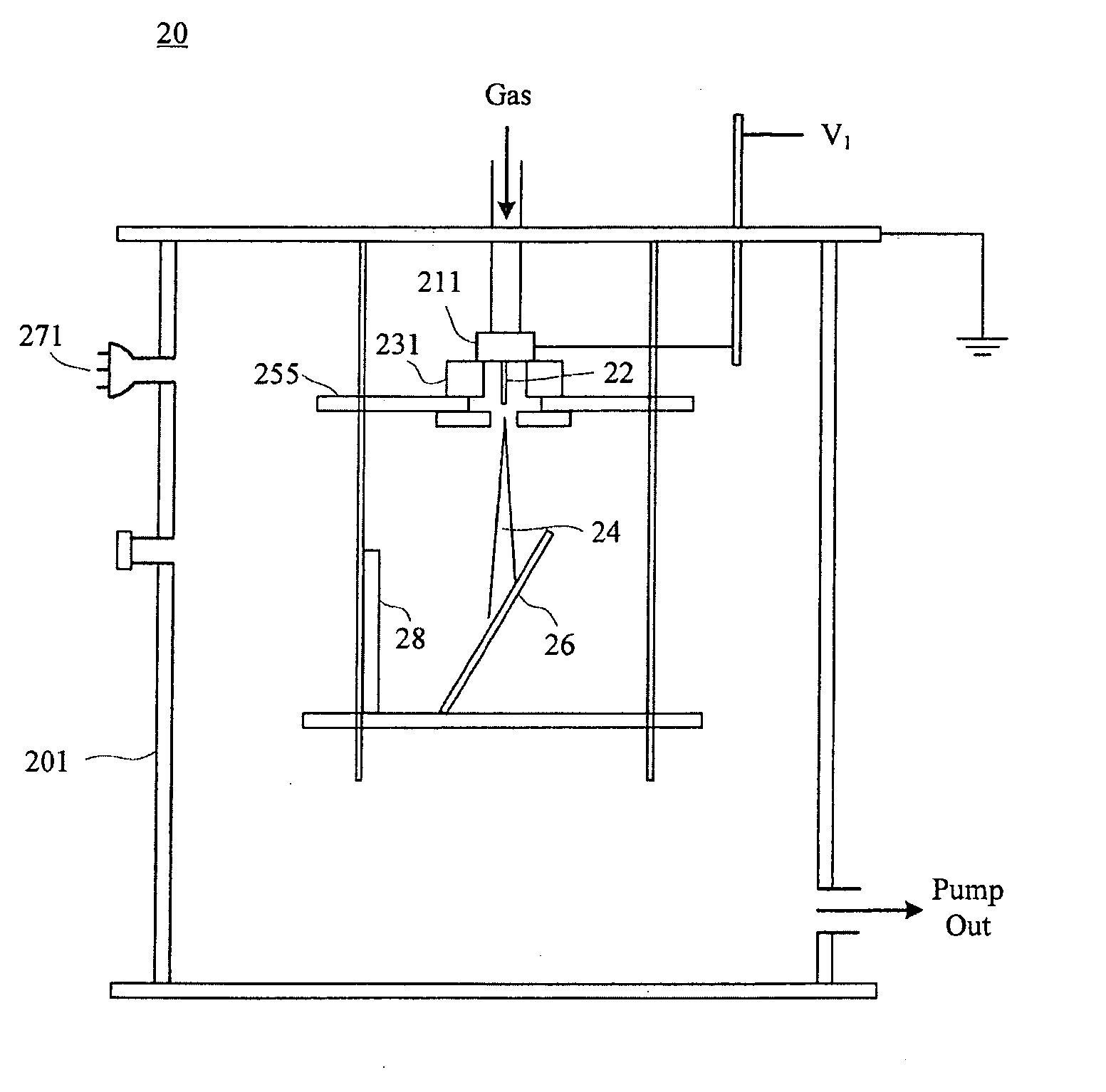

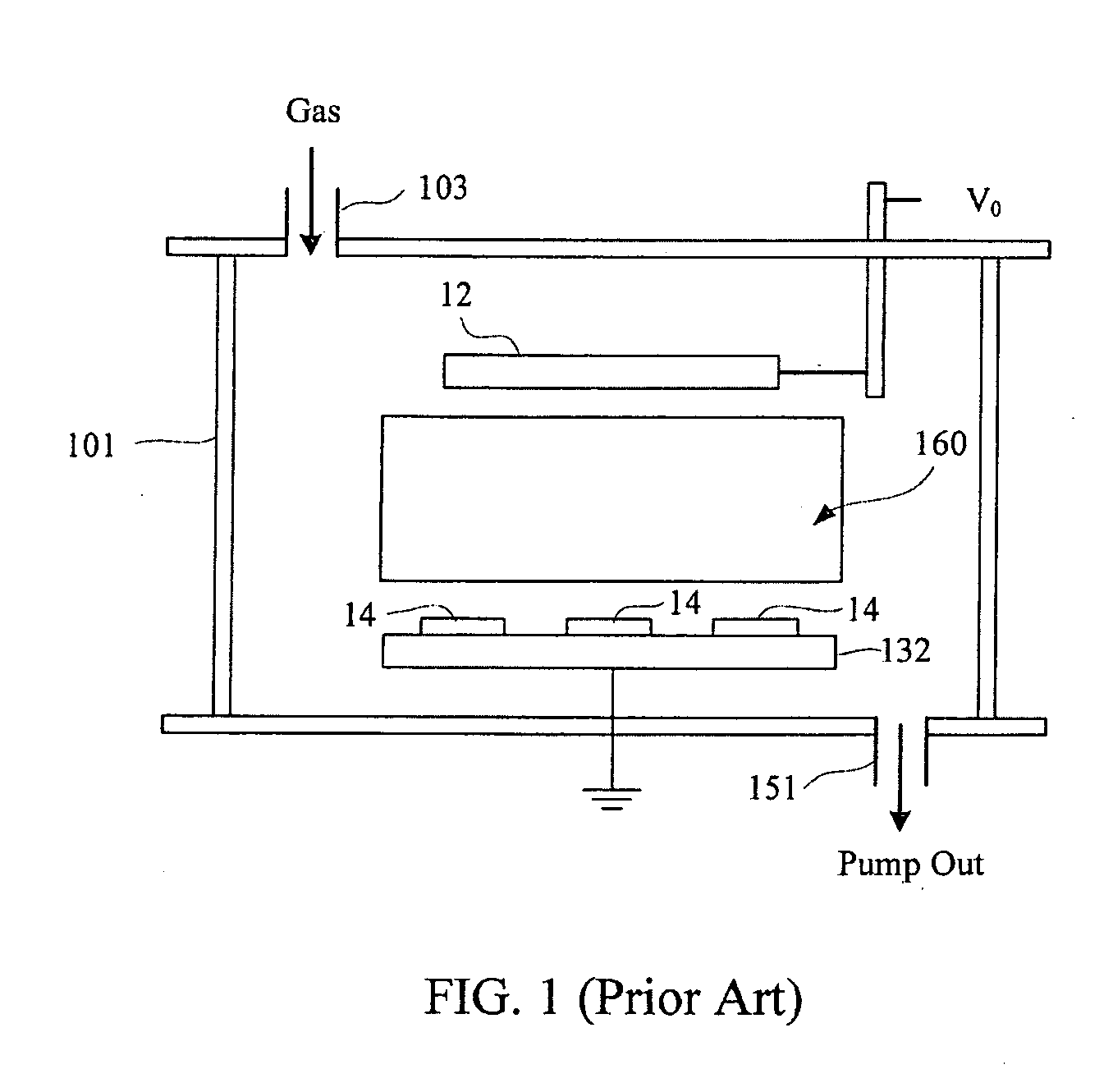

Capillaritron ion beam sputtering system and thin film production method

InactiveUS20090236217A1Reduce the impactReduce surface roughnessCellsElectric discharge tubesZinc atomRoot mean square

A capillaritron ion beam sputtering system and a thin film production method are disclosed. By utilizing reactive capillaritron ion beam sputtering deposition, argon and oxygen are passed through a capillaritron ion source simultaneously. Argon is being ionized and accelerated by a voltage to bombard a zinc target and create zinc atoms, while oxygen atoms are created at the same time. Zinc atom and oxygen atom are combined to form ZnO to deposit on a substrate. The stoichiometric properties, deposition rate, transmission properties, surface roughness and film density of the as-deposited film can be altered by adjusting capillaritron ion beam energy and oxygen partial pressure. Using preferred processing parameters, the root-mean-square surface roughness of the as-deposited film can be smaller than 1.5 nm, while the transmission coefficient at visible range can be greater than 80%.

Owner:NAT TAIWAN UNIV OF SCI & TECH

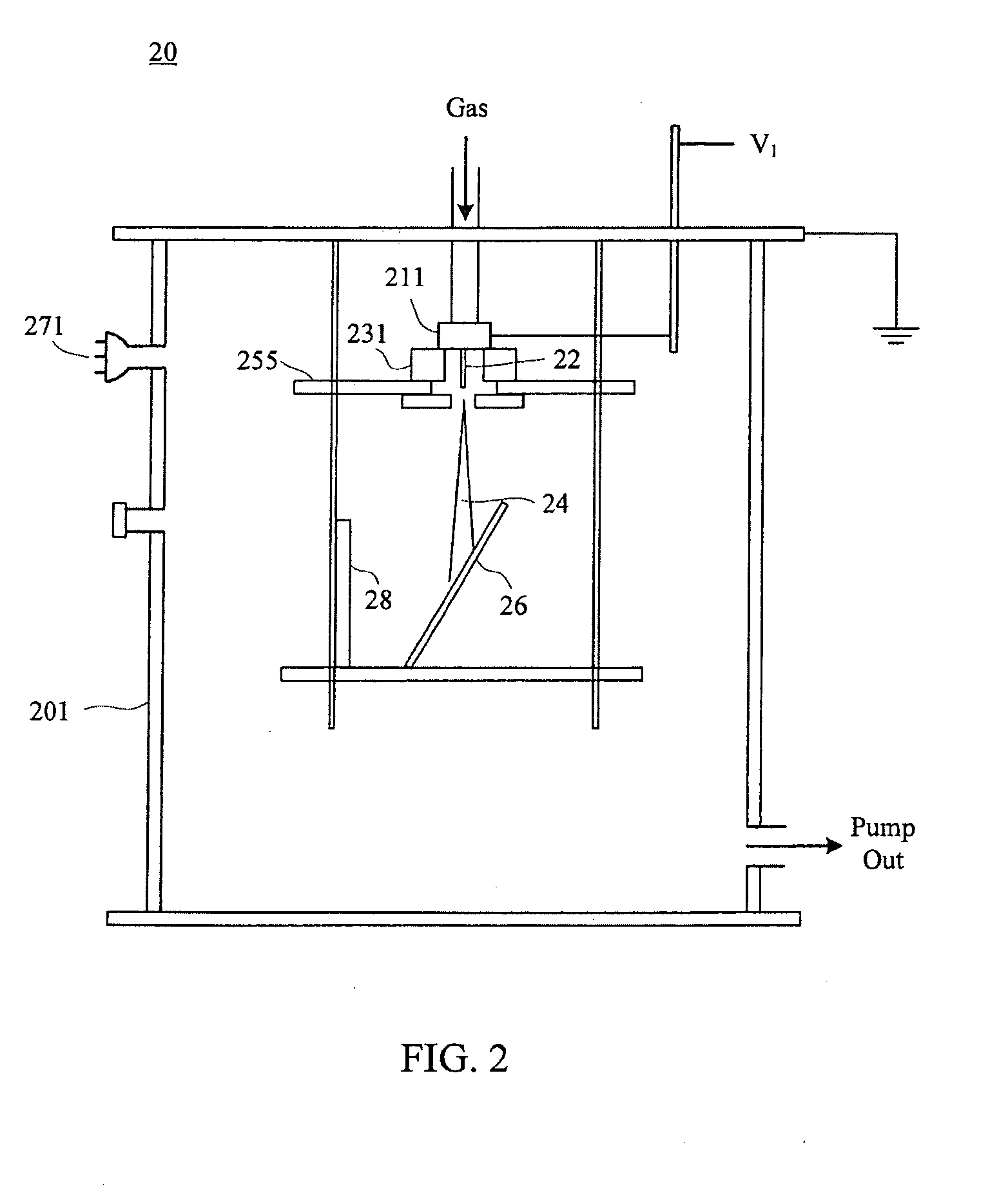

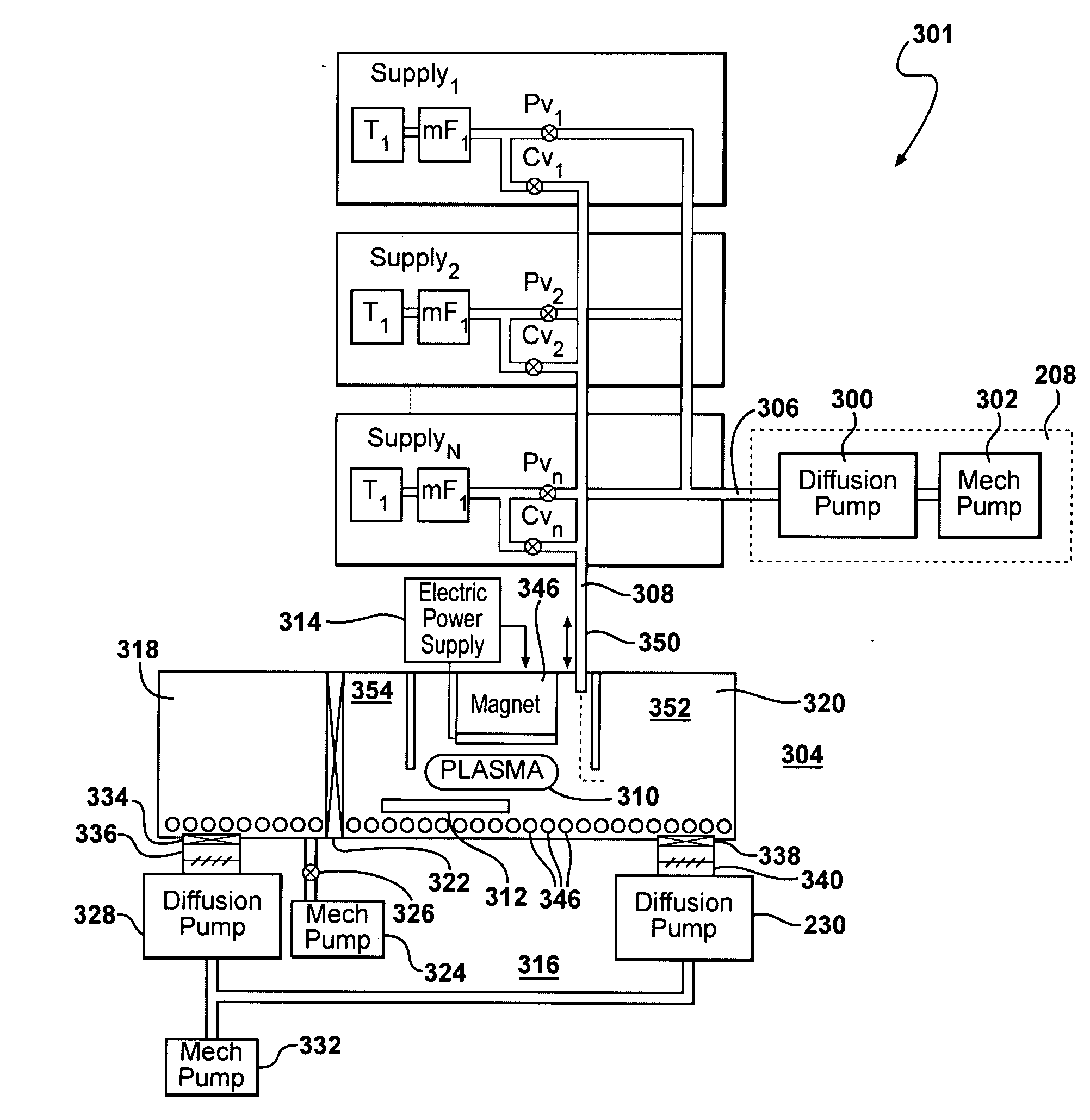

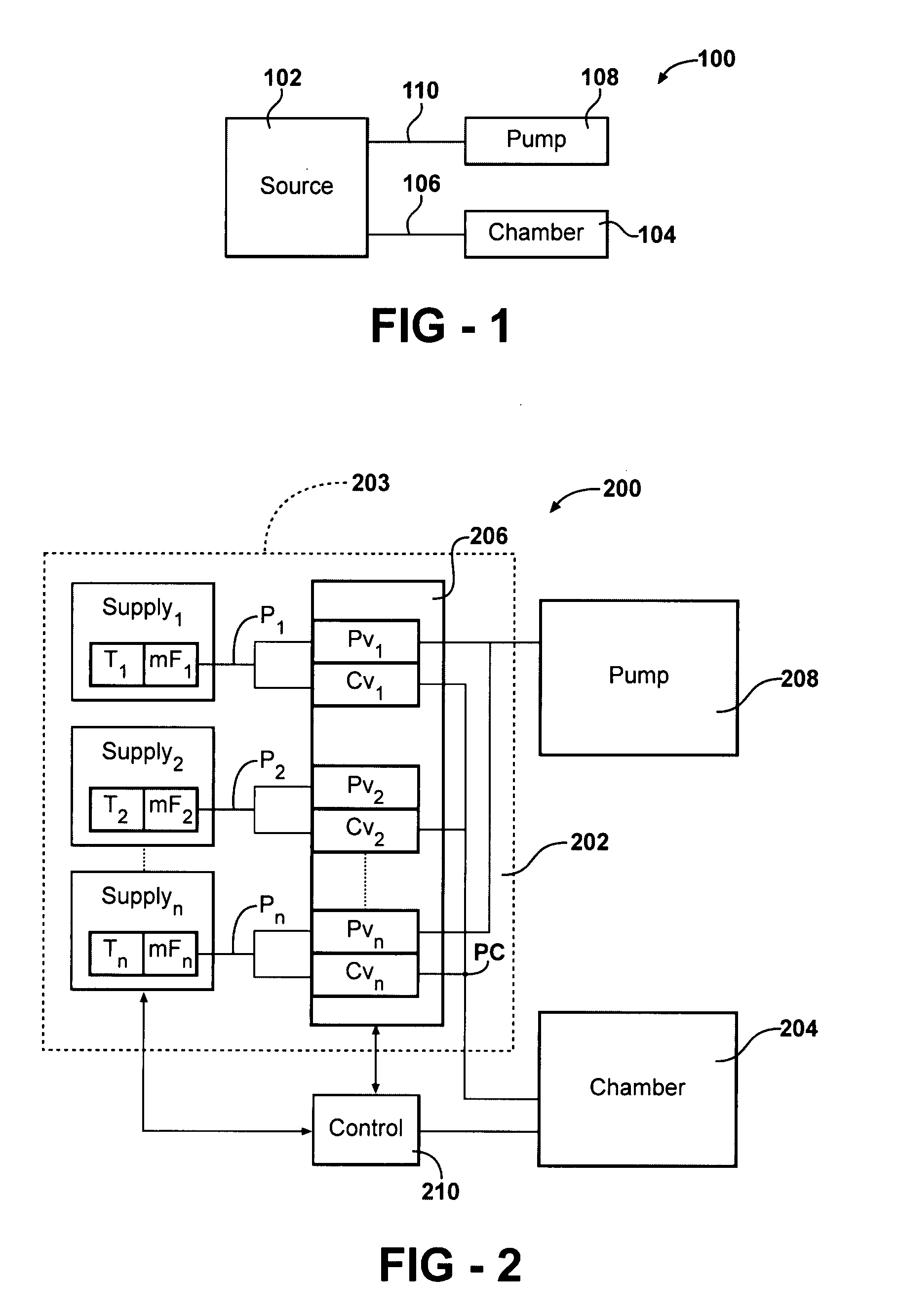

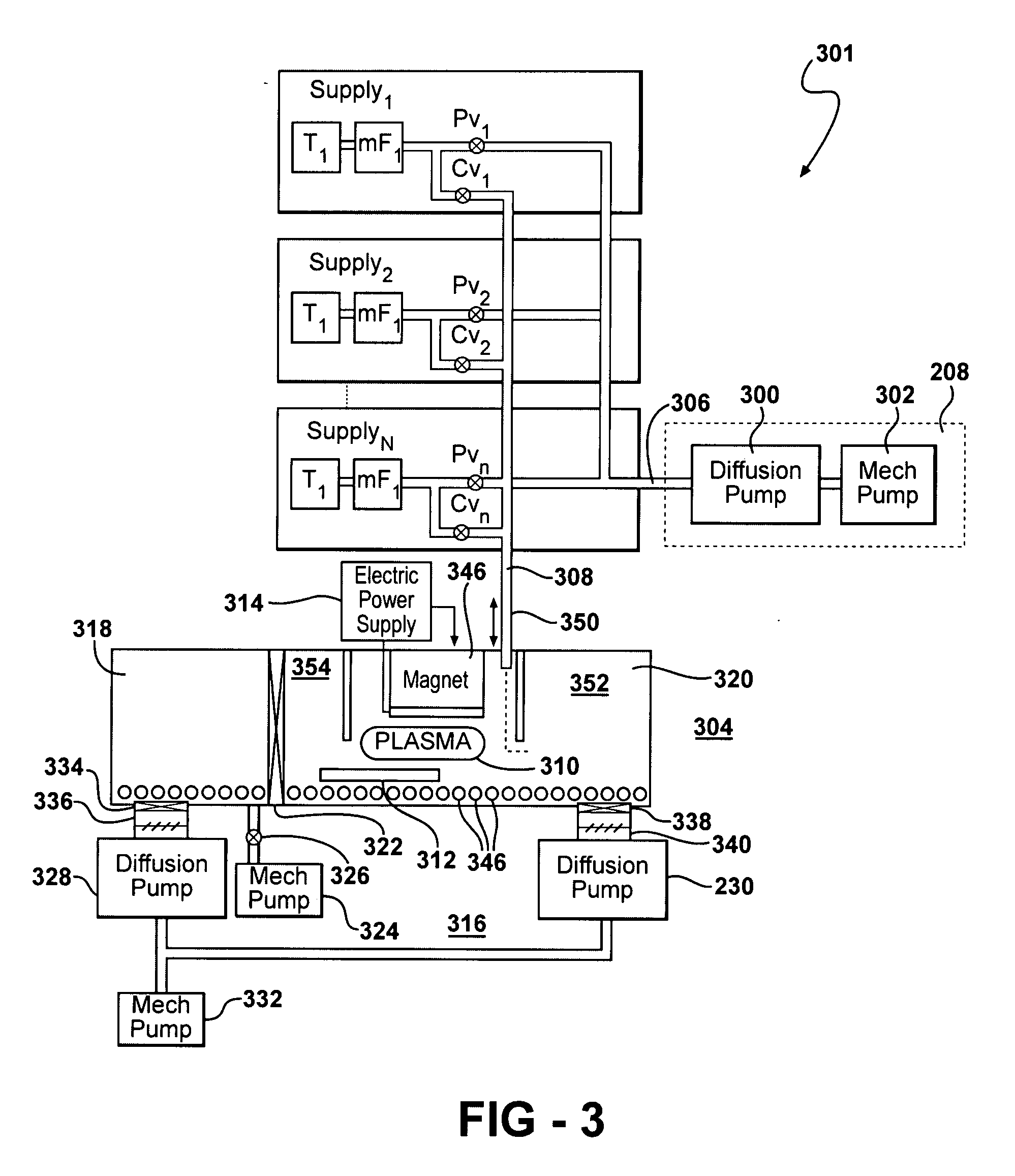

Method and apparatus for deposition

A deposition system supplies a continuous flow of process gases and sequentially selects among the flowing process gases for delivery to a reaction chamber. In the reaction chamber the delivered process gas acts as an ionizing species and thereby effects the deposition of a target substance upon a substrate. Gases not selected for delivery to the reaction chamber are swept away by a vacuum pump. By making a plurality of process gases continuously available, sequentially selecting among the available process gases, and pumping unused gases away before they enter the reaction chamber, such a system and method provides for continuous, sequential, uninterrupted deposition of a variety of substances, while maintaining desired flow rates and chamber pressures.

Owner:OVONYX

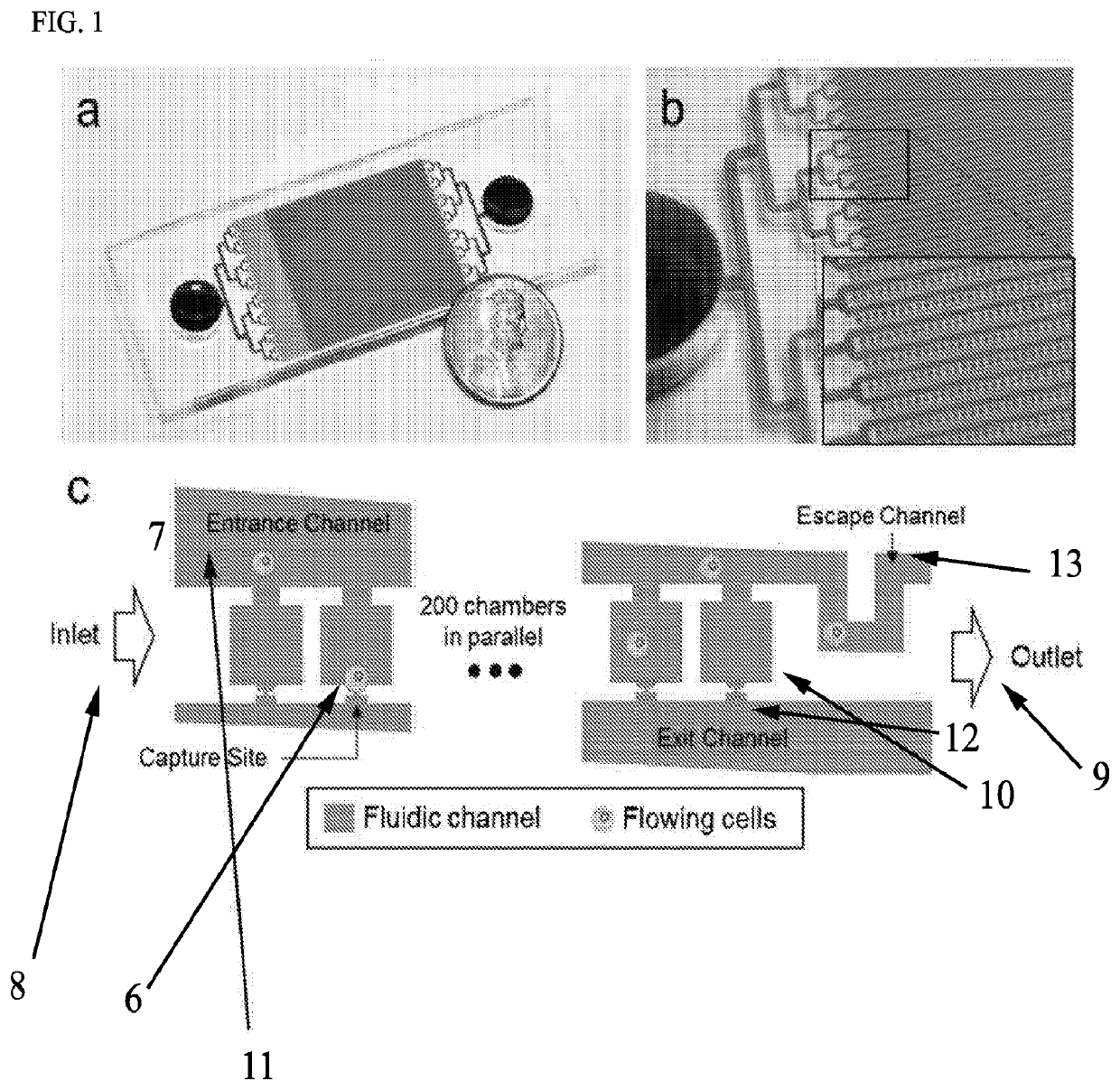

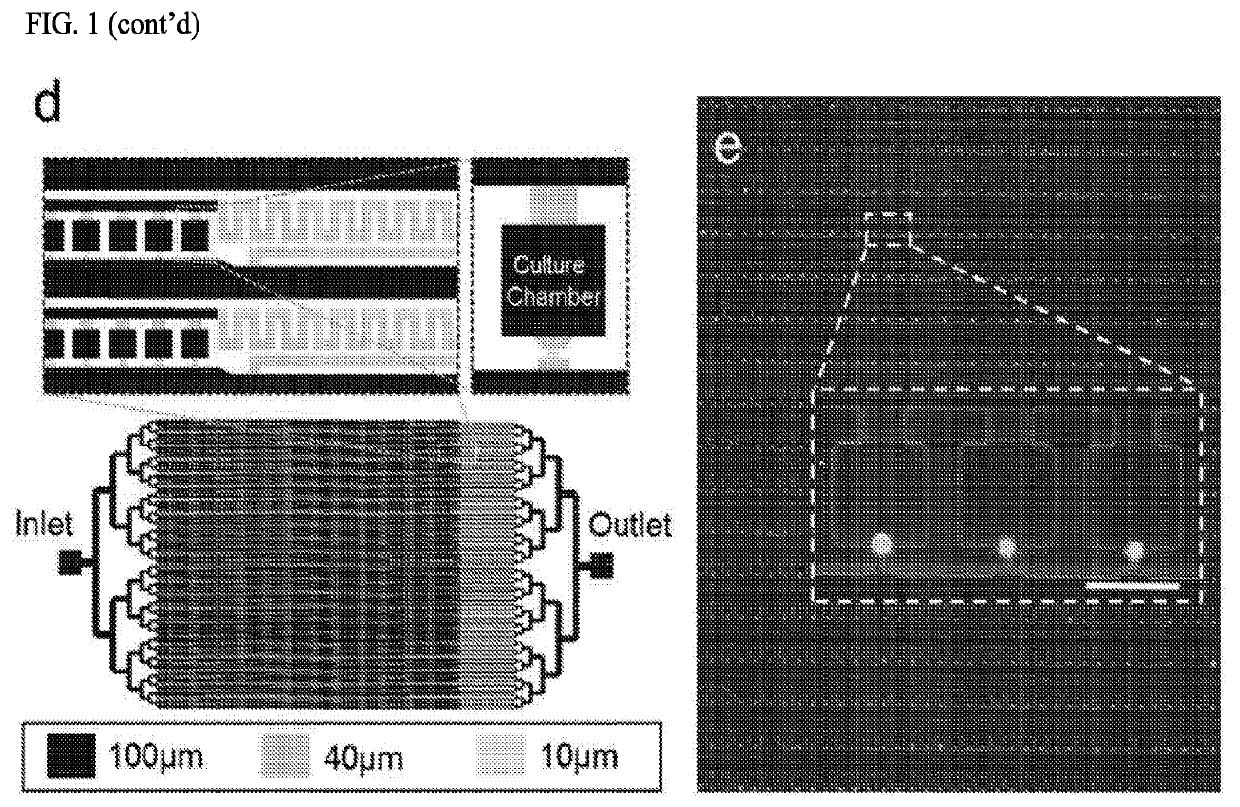

Systems and methods for whole cell analysis

ActiveUS20190344270A1Increase flow rateReduce flow rateLaboratory glasswaresBiomass after-treatmentGene expressionBioinformatics

The present disclosure relates to systems and methods for whole cell analysis. In particular, the present disclosure relates to single cell genomic analysis (e.g., gene expression analysis.

Owner:RGT UNIV OF MICHIGAN

Electronic woodwind instrument

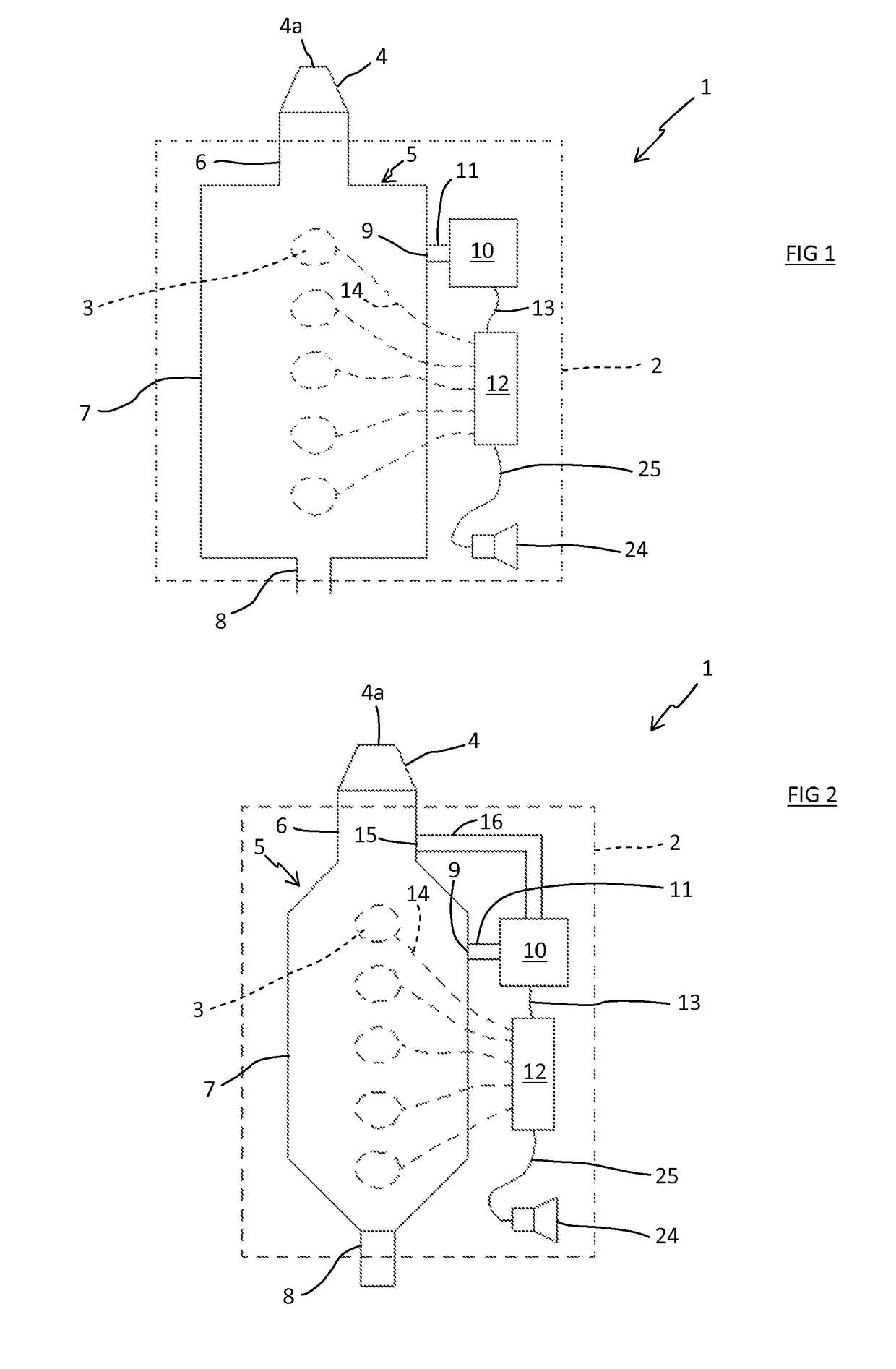

ActiveUS20180137846A1Maintain flow rateEasy to measureElectrophonic musical instrumentsEngineeringHandling system

Disclosed is an electronic woodwind instrument for that allows adjusting the behavior thereof to be adjusted to approach as much as close as possible to that of an acoustic woodwind instrument. The instrument includes a mouthpiece, a body provided with keys and a channel connected to the mouthpiece and leading to the outside of the instrument, at least one pressure sensor configured to deform under the action of breath, and an electronic processing system connected to the keys and the pressure sensor and configured to produce musical notes according to the handling of the keys and the measurement of breath. The channel includes an inlet tube, an outlet tube and an intermediate chamber, the elements being configured to pressurize the chamber when the musician blows into the mouthpiece. The chamber includes a measuring port on to which the pressure sensor is connected.

Owner:AODYO

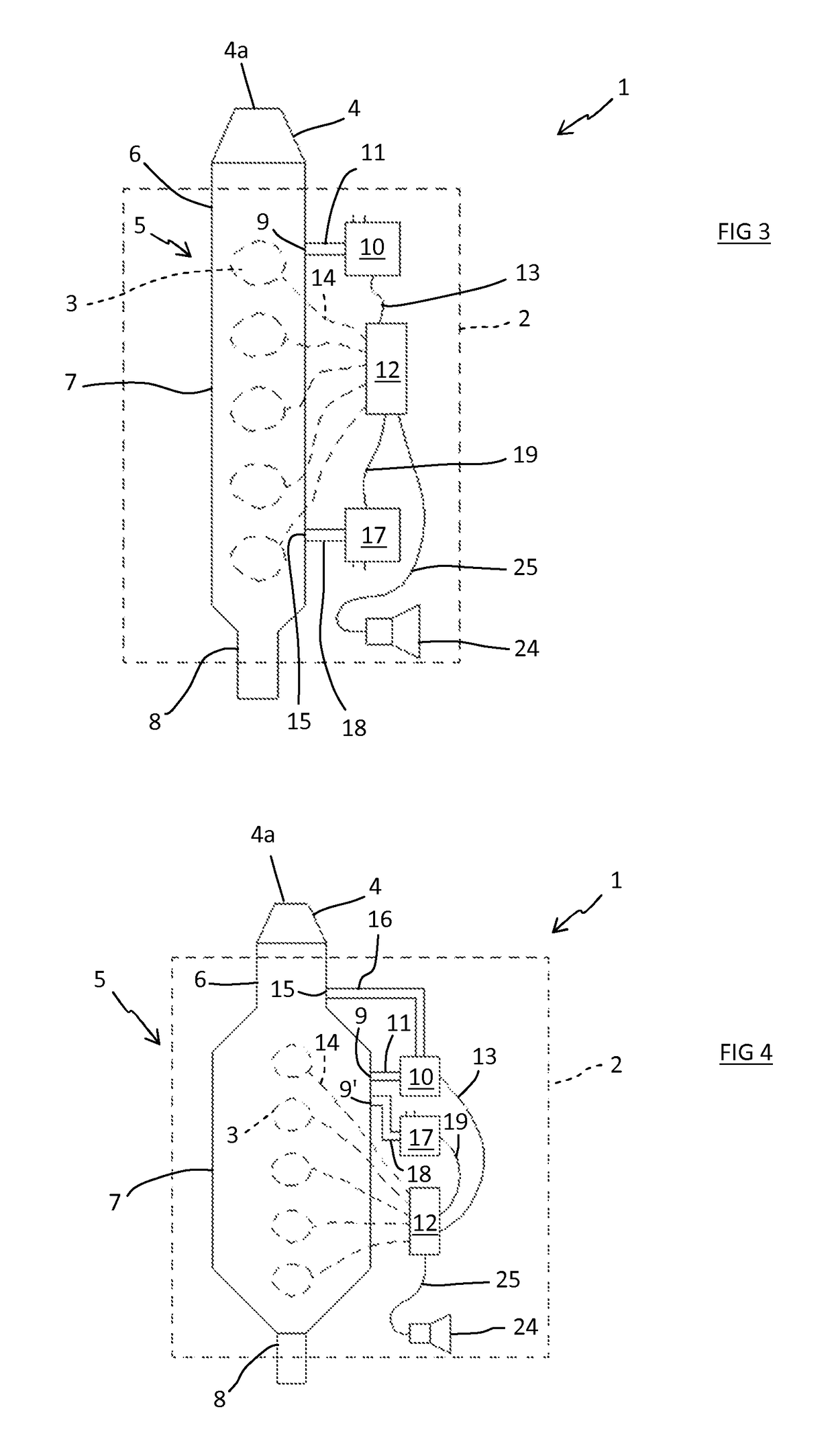

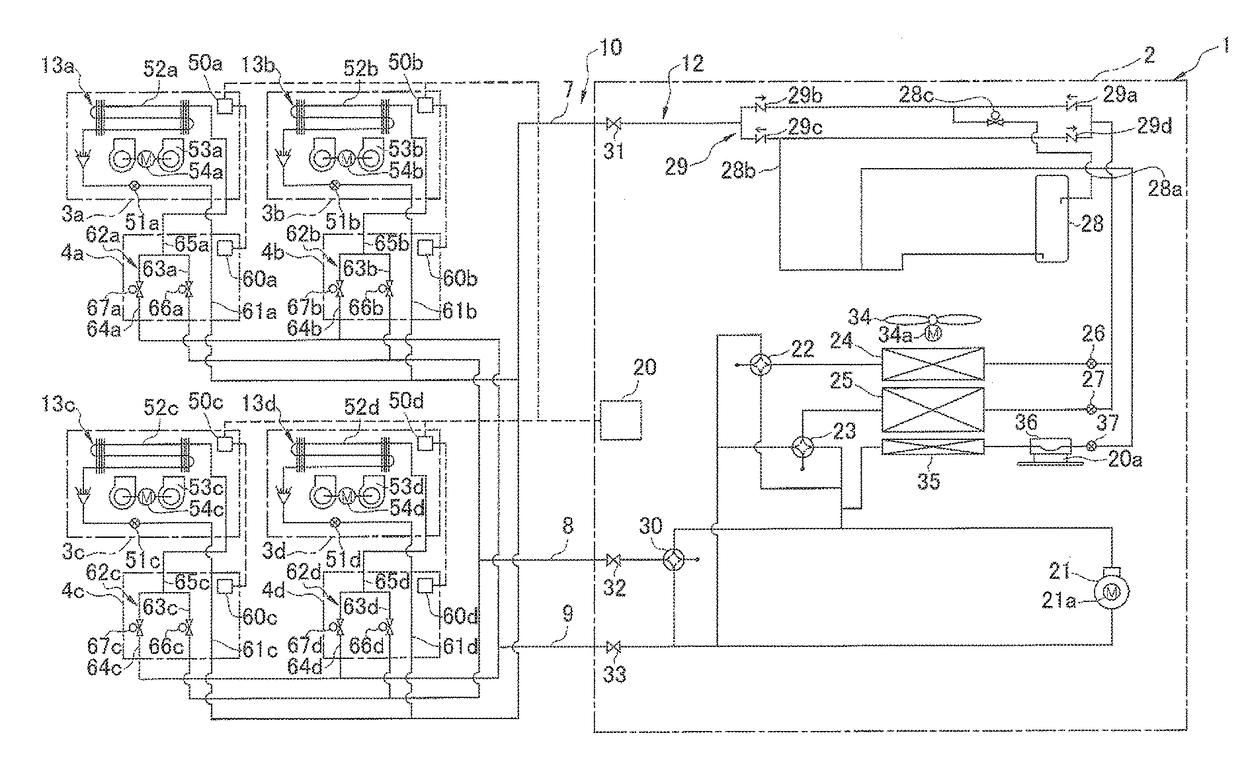

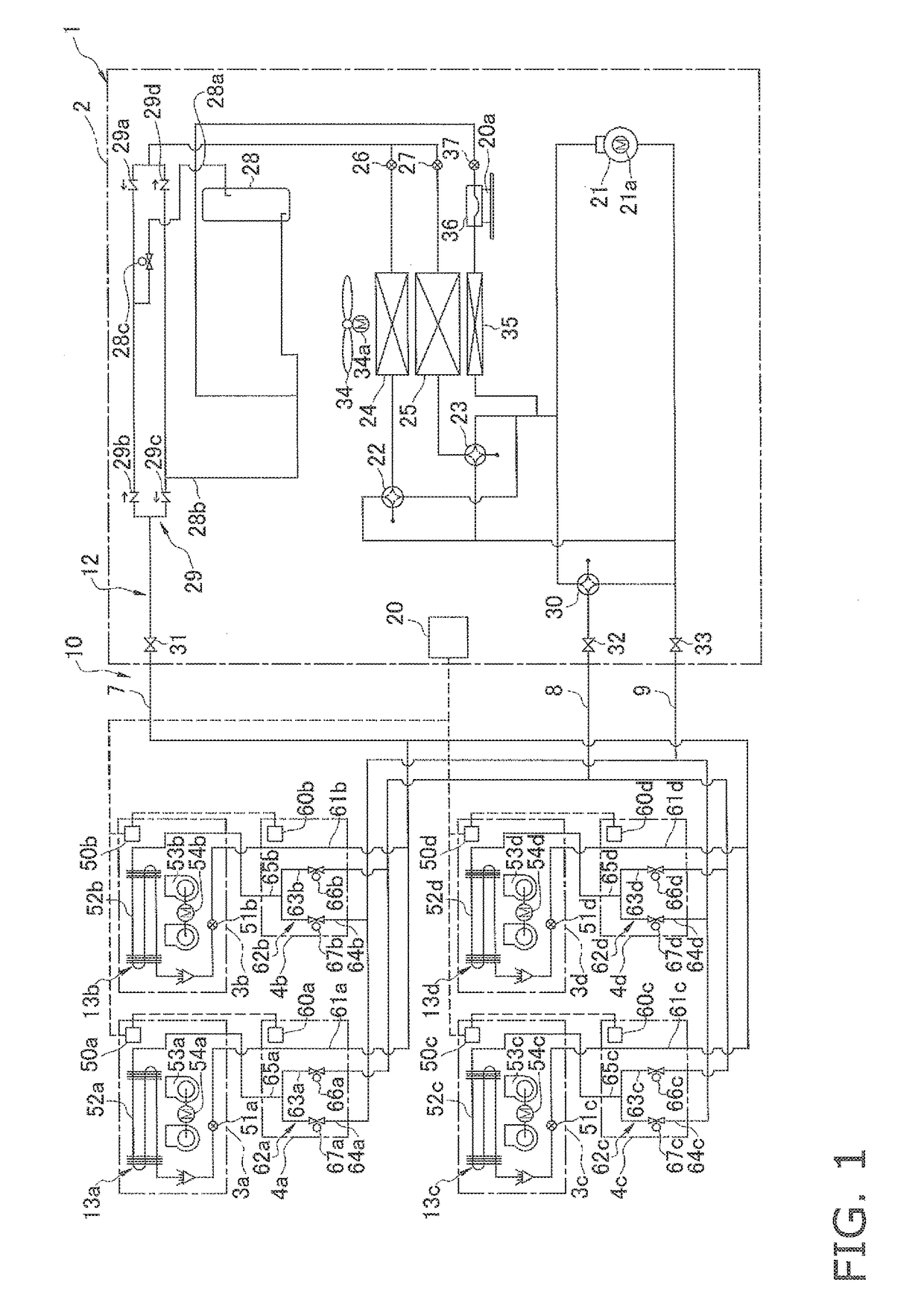

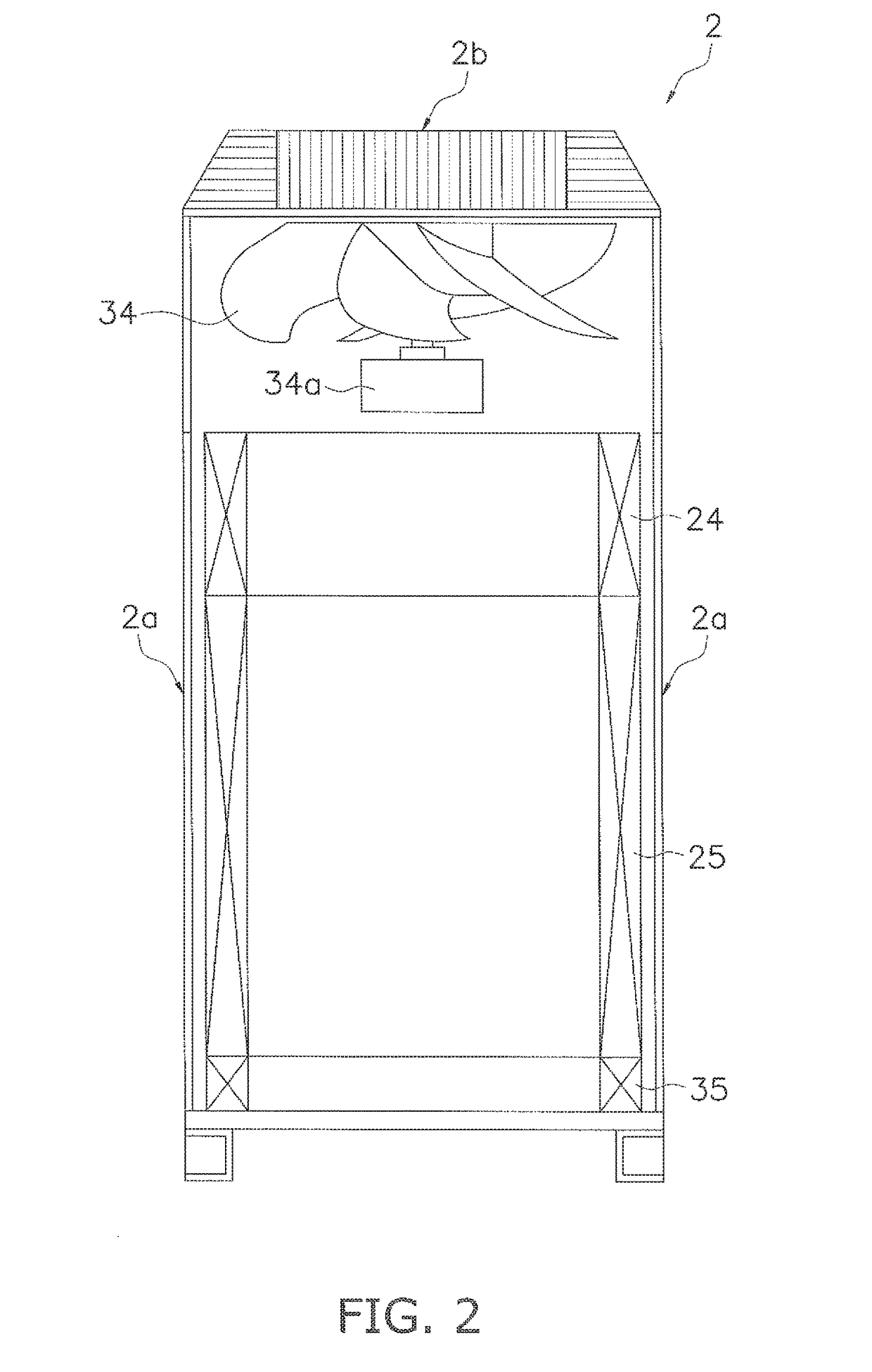

Heat-recoverty-type refrigerating apparatus

ActiveUS20160238285A1Maintain flow rateCompressorCompression machines with several condensersEngineeringHigh pressure

A heat-recovery-type refrigerating apparatus includes a compressor, a heat-source-side heat exchanger, and a plurality of usage-side heat exchangers, and refrigerant is sent from the usage-side heat exchanger functioning as a refrigerant radiator to the usage-side heat exchanger functioning as a refrigerant evaporator, whereby heat can be recovered between the usage-side heat exchangers. Here, a portion of the heat-source-side heat exchanger is configured as a precooling heat exchanger for always circulating high-pressure vapor refrigerant discharged from the compressor, and a refrigerant cooler for cooling an electrical equipment item is connected to a downstream side of the precooling heat exchanger.

Owner:DAIKIN IND LTD

Method for clearing pipelines in manufacturing process of aluminium oxide

InactiveCN101580943AImplement cleanup tasksAchieve recyclingAluminium oxides/hydroxidesDecompositionEngineering

The invention provides a method for clearing pipelines in the manufacturing process of aluminium oxide, which is applicable to the clearance of scars generated in the pipeline transportation section in the manufacturing process of aluminium oxide, in particular to the method for clearing the scars inside the pipelines. The clearing process is characterized in that the pipeline is full of floating NaOH alkali liquor with the temperature of 93-103 DEG C in the clearing process; the NaOH alkali liquor dissolves the scars in the pipelines and the scars can be cleared by the floating and eroding of the alkali liquor. The wet clearing method of pipelines in the process of manufacturing the aluminium oxide by the sintering method can realize scar decomposition and return to the flow by utilizing the principle that alkali solution with certain temperature, concentration and flow rate can dissolve the scars, thus realizing the recycling of the pipelines for transmitting materials in the manufacturing process of the aluminium oxide and improving production capability and device productivity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

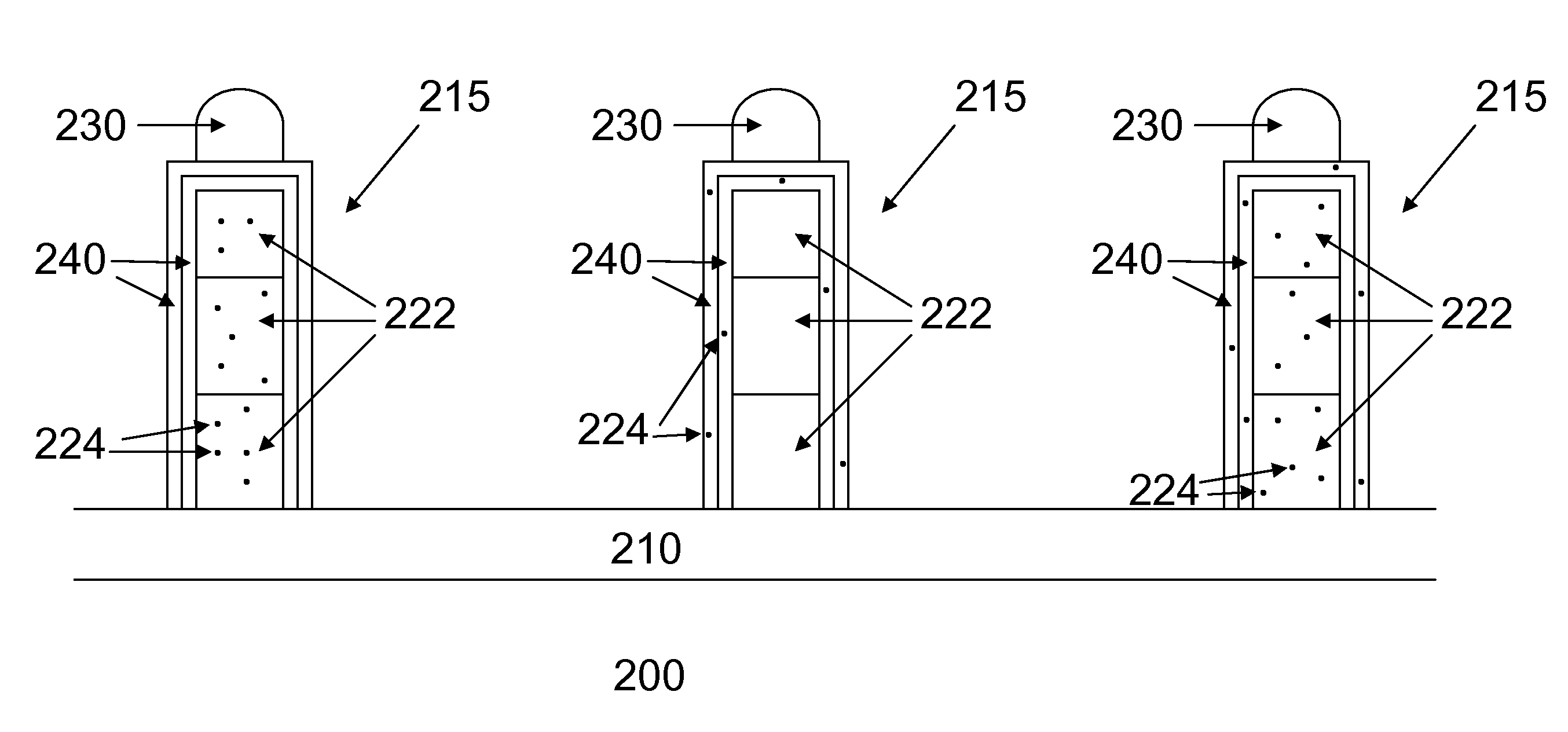

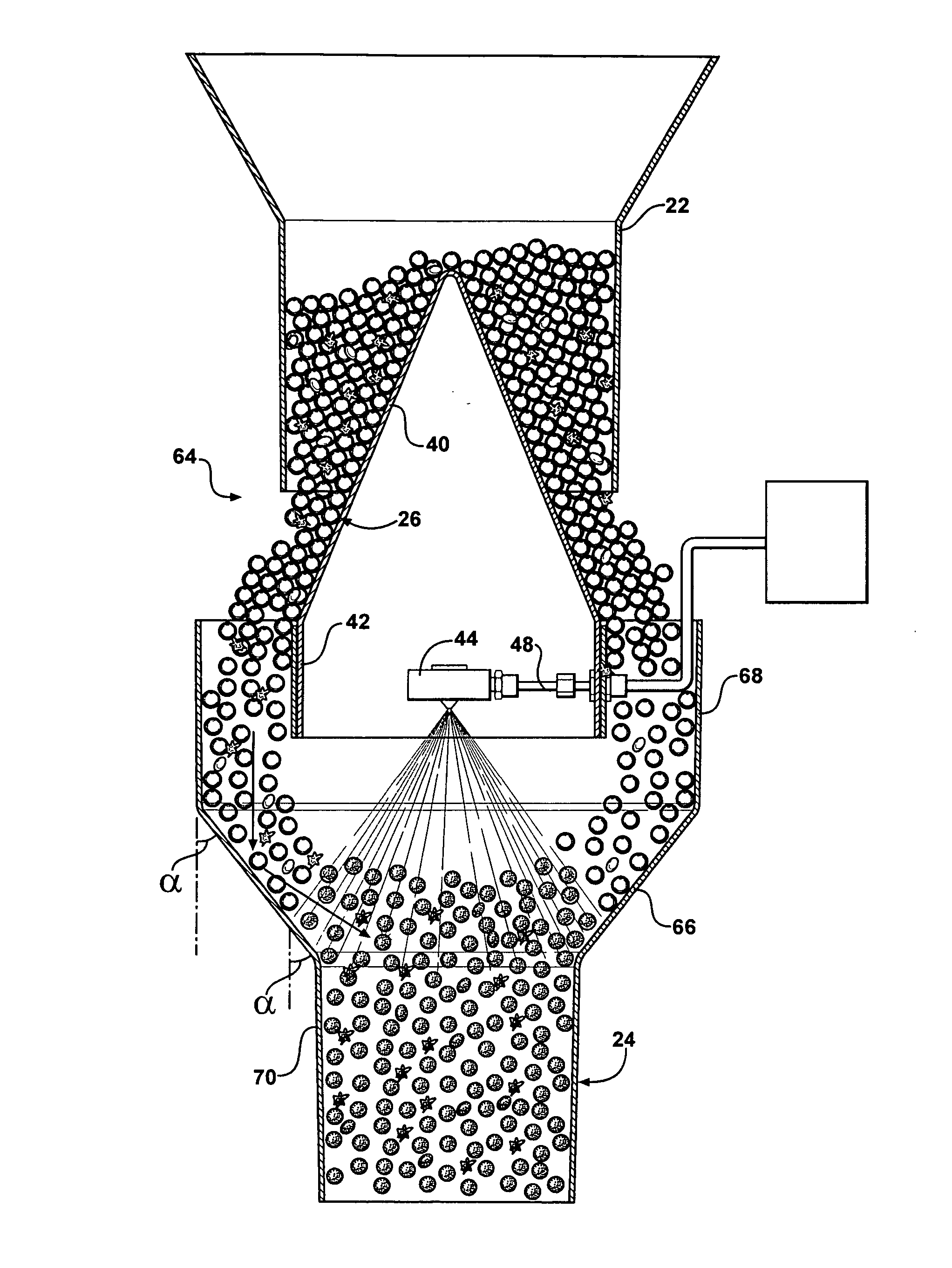

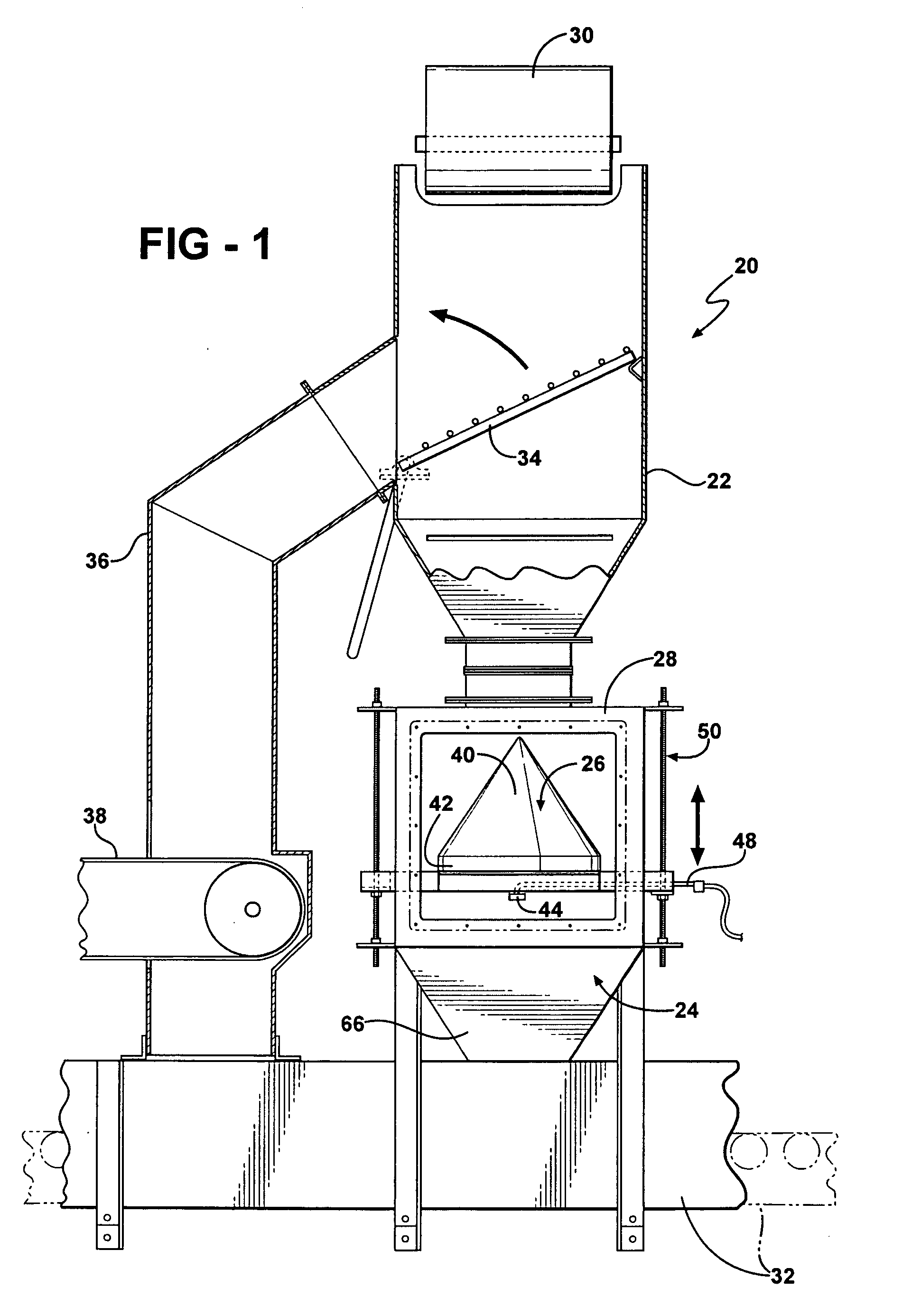

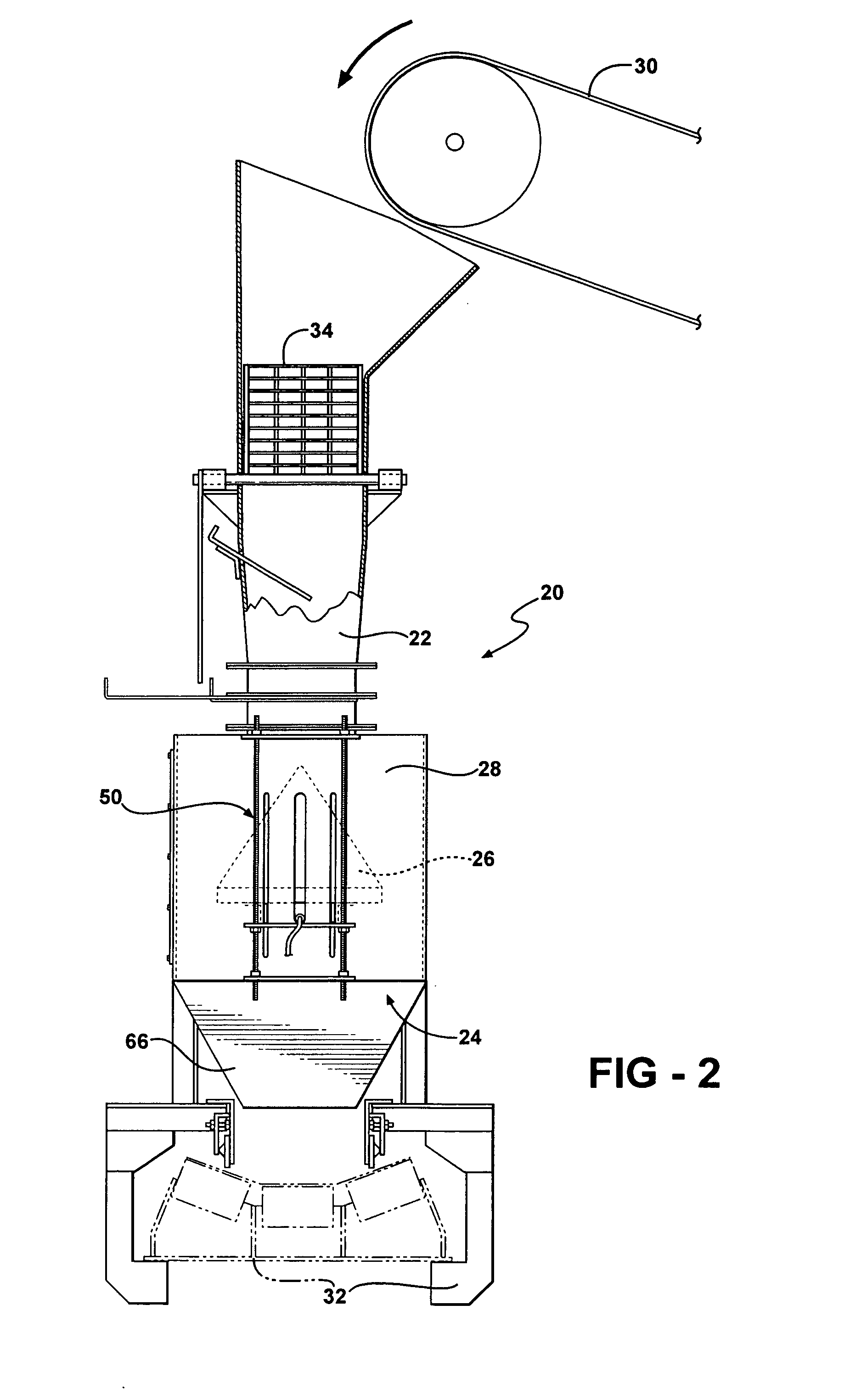

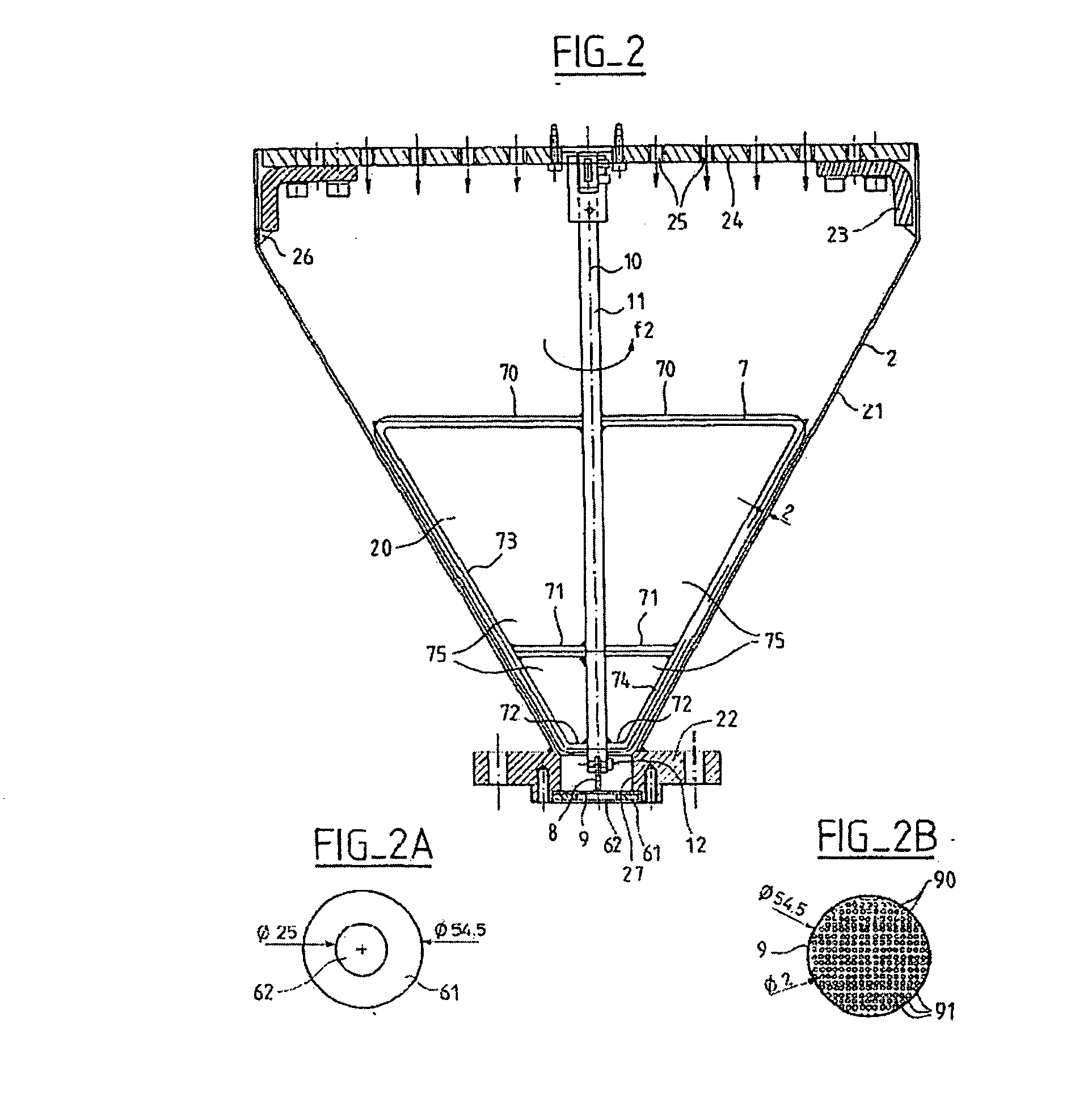

Apparatus for treating particles utilizing a flow control device

InactiveUS20070196573A1Effective treatmentMinimal amountGranule coatingLiquid/solution decomposition chemical coatingEngineeringCoating

An apparatus and method for treating a plurality of particles with a coating. The apparatus includes a feed chute and a diffuser having an angled wall to define a gap between the feed chute and the diffuser. An applicator sprays a coating for treating a plurality of particles and an exit chute captures the treated particles. A flow control device is provided for dynamically adjusting a size of the gap between the feed chute and the diffuser as the particles pass through the gap for ensuring a predetermined flow rate of the particles about the diffuser is maintained.

Owner:SURFACE CHEMISTS OF FLORIDA

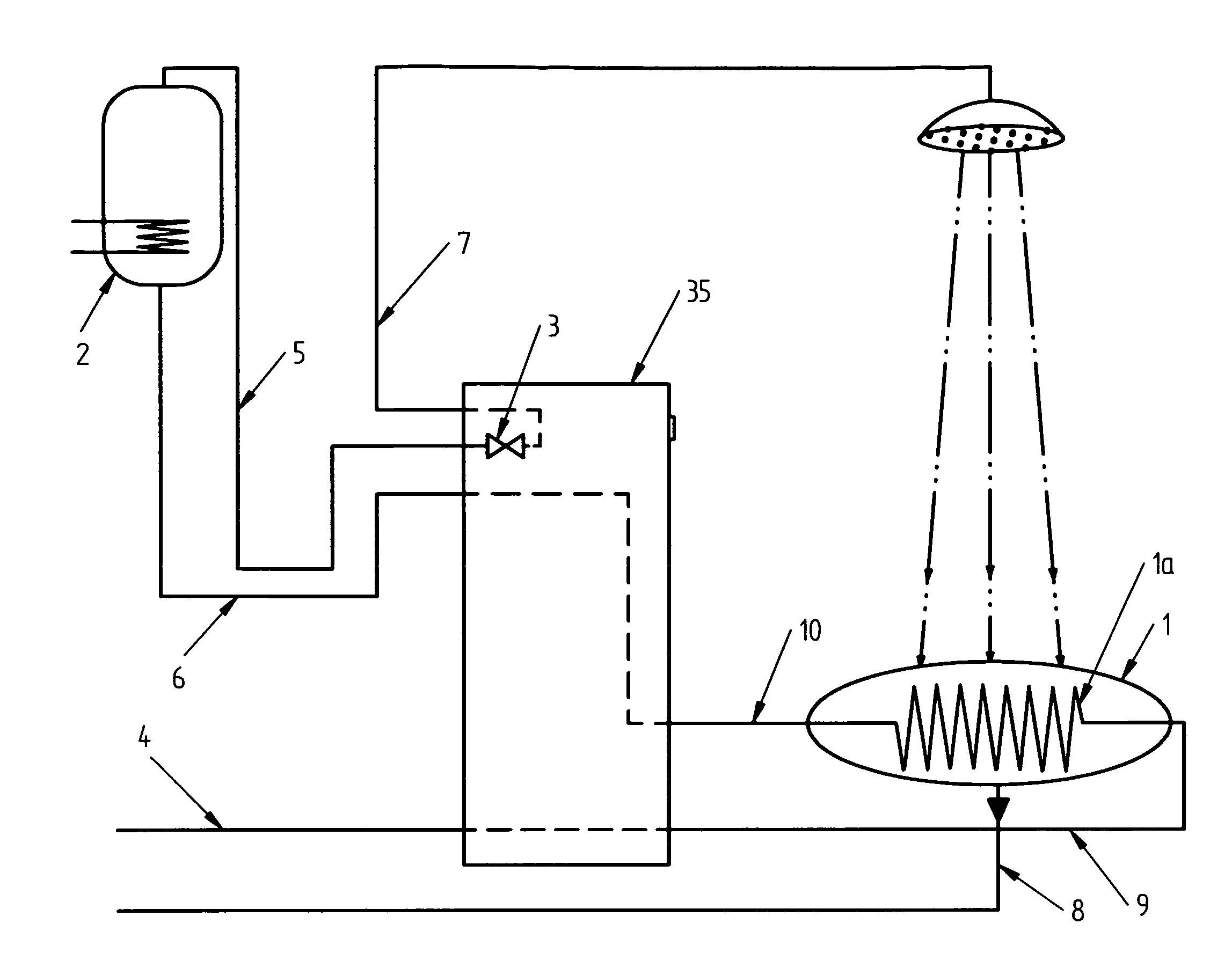

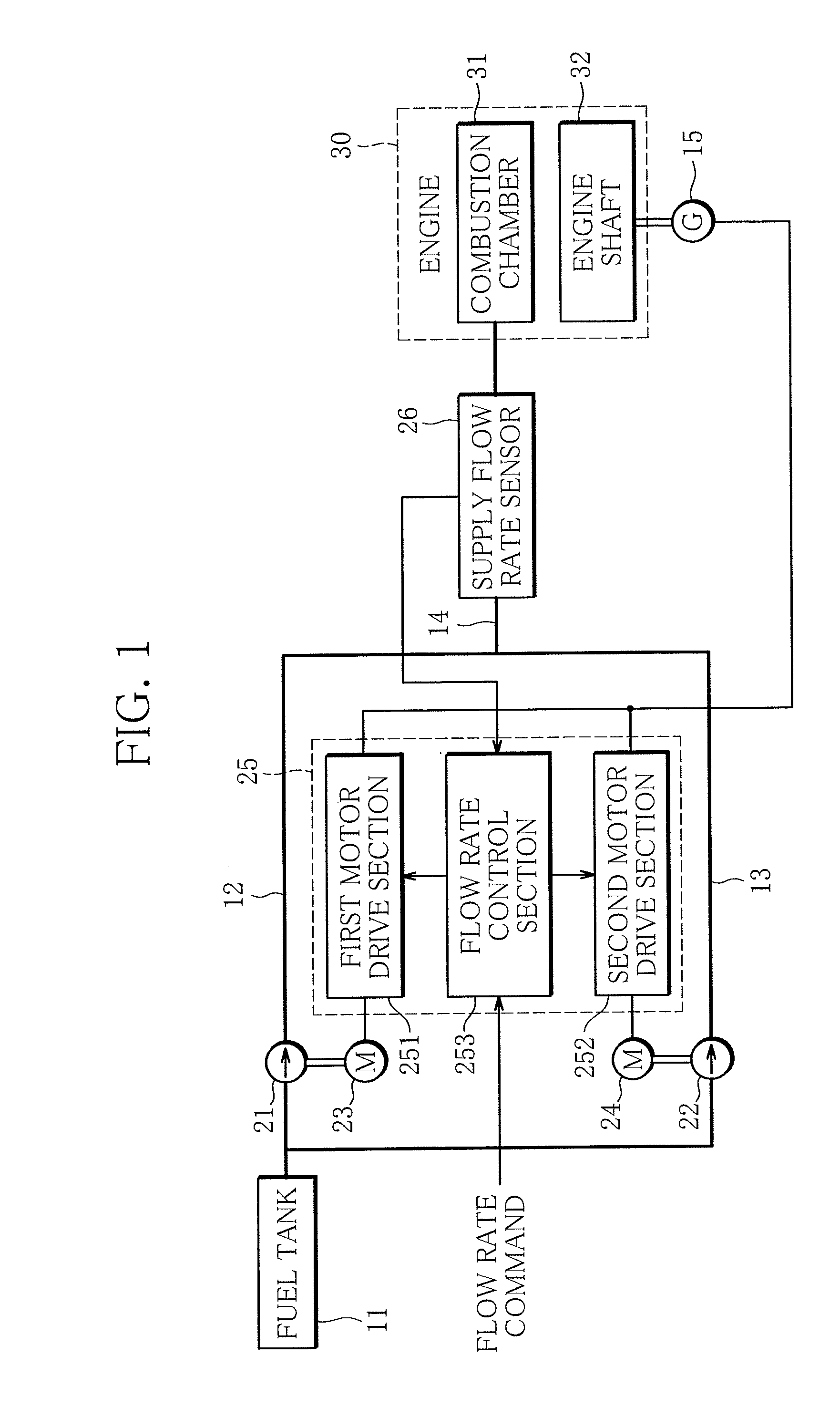

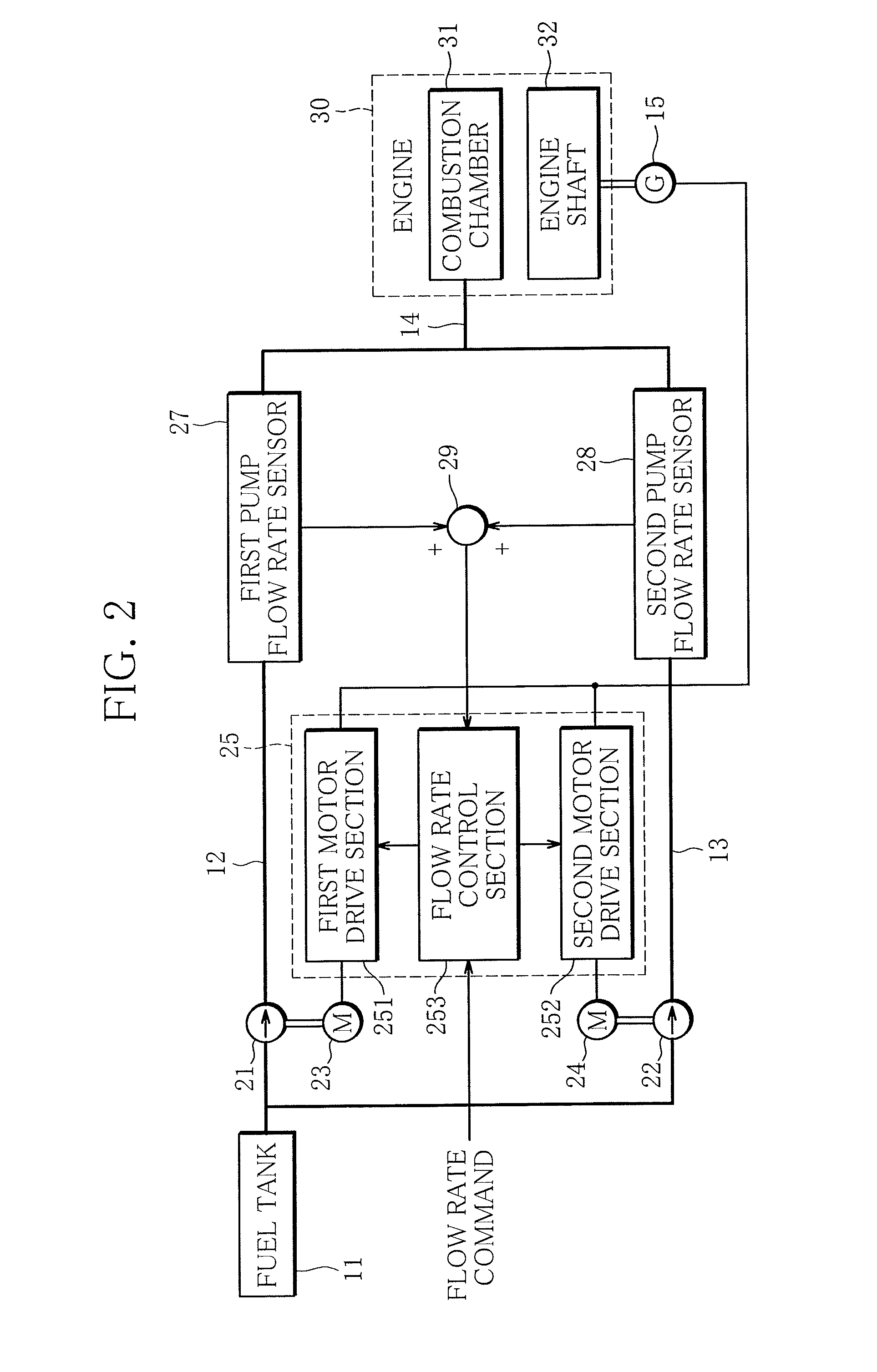

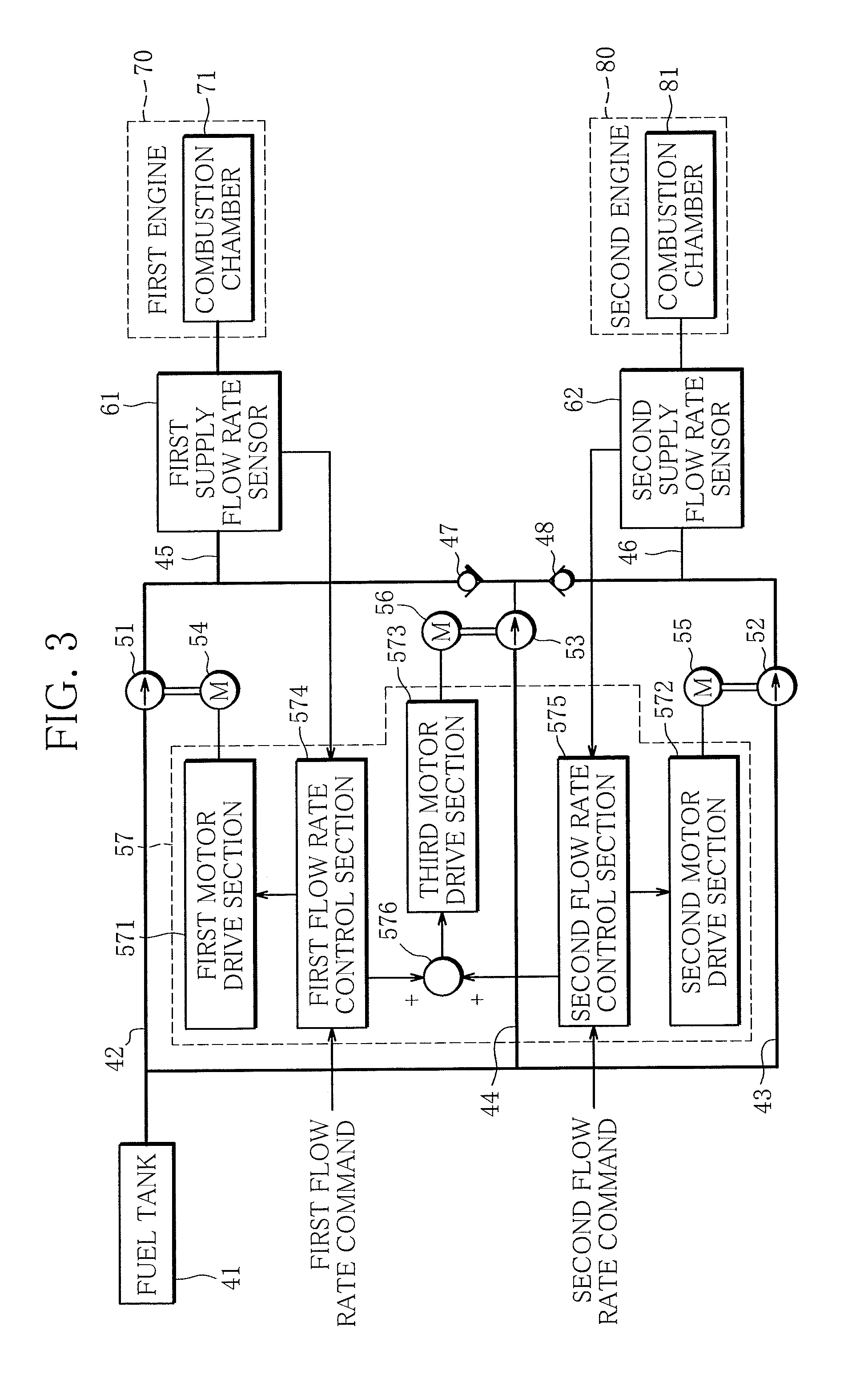

Fluid supply device

A fuel supply device according to the present invention comprises a first fuel pump for forcing fuel from a fuel tank to a fuel passage, a first electric motor for driving the first fuel pump, a second fuel pump for forcing fuel from the fuel tank to the fuel passage, a second electric motor for driving the second fuel pump, a supply flow rate sensor for detecting flow rate in the supply passage, and a control device for controlling the flow rate in the supply passage to follow a desired value thereof, by regulating rotational speeds of the first and second electric motors depending on a difference between the desired value and a detected value of flow rate in the supply passage.

Owner:IHI AEROSPACE CO LTD

Method of controlling operation of rock drilling rig, and rock drilling rig

Owner:SANDVIK MINING & CONSTR OY

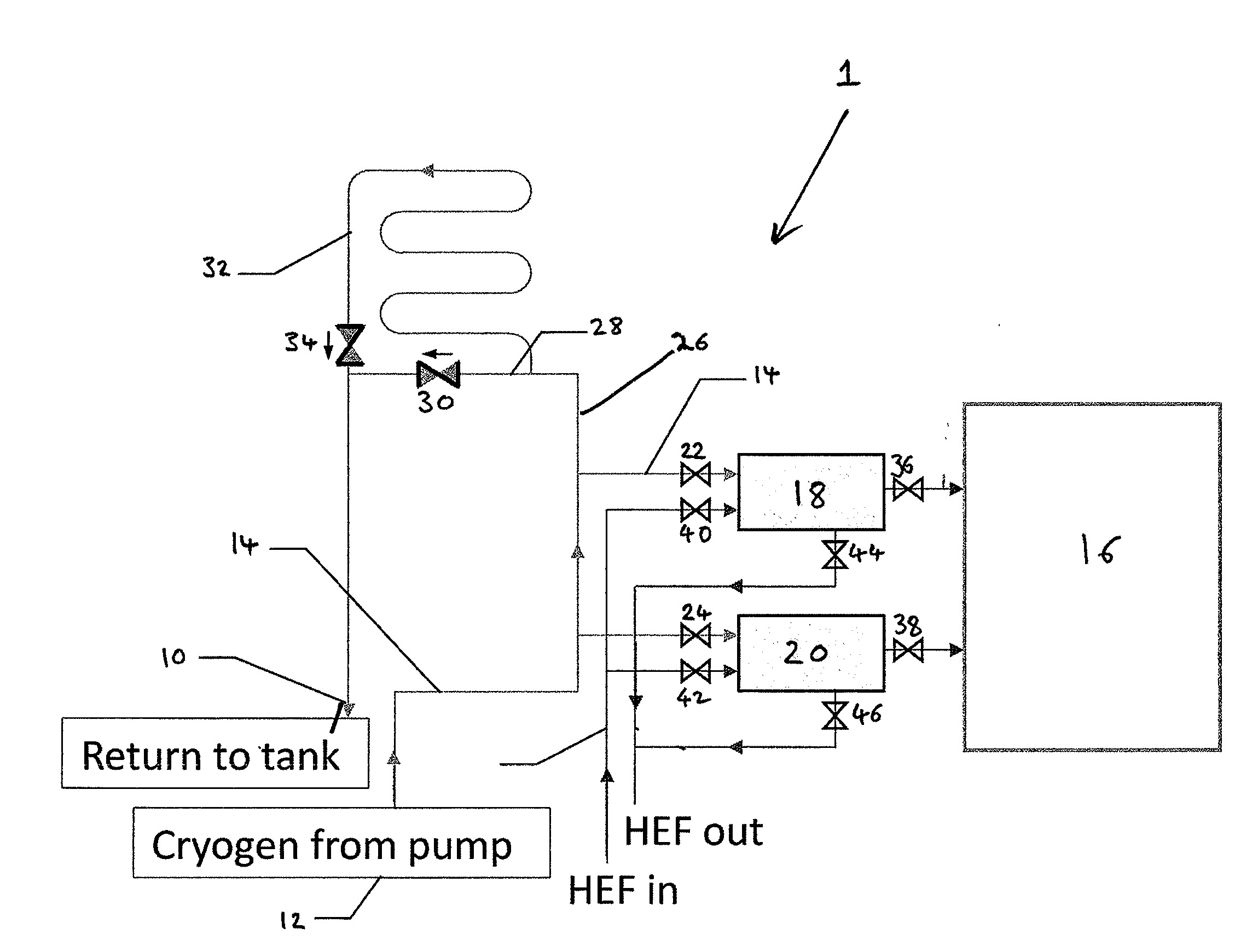

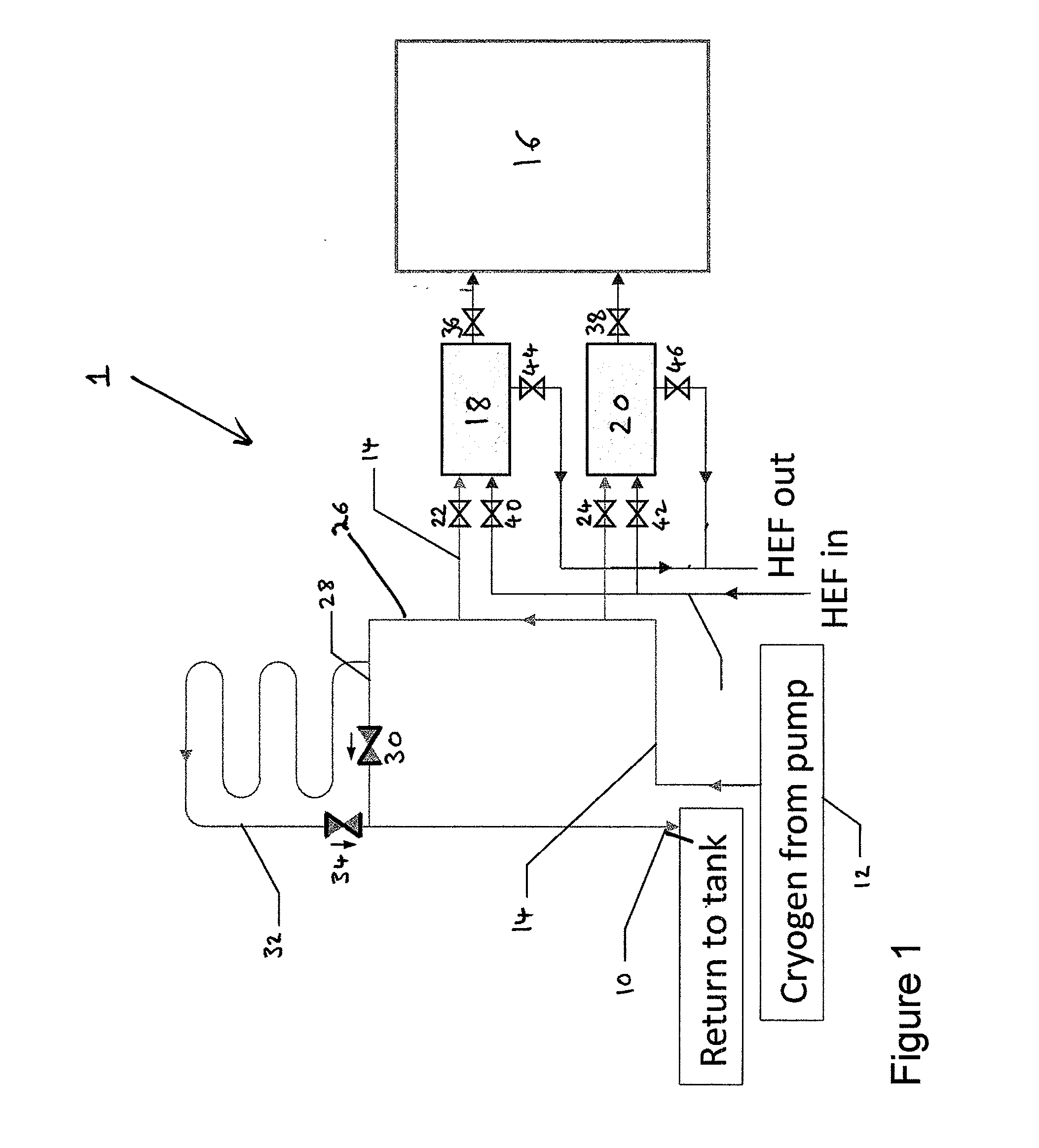

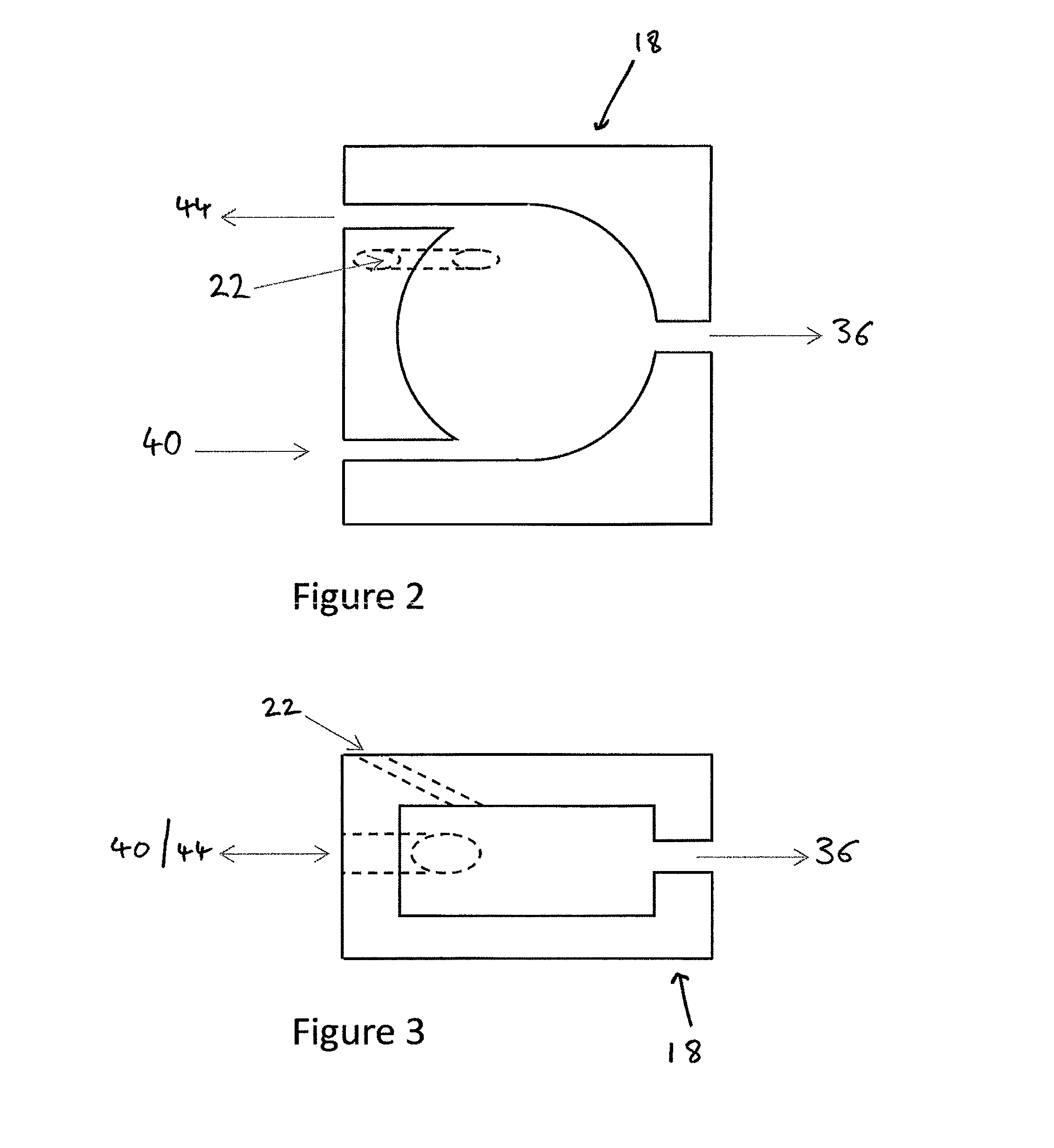

Cryogenic engine system

InactiveUS20150226093A1Reduce pulsationReduce heat transferInternal combustion piston enginesFuel supply apparatusProcess engineeringMixed systems

Owner:DEARMAN ENGINE CO LTD

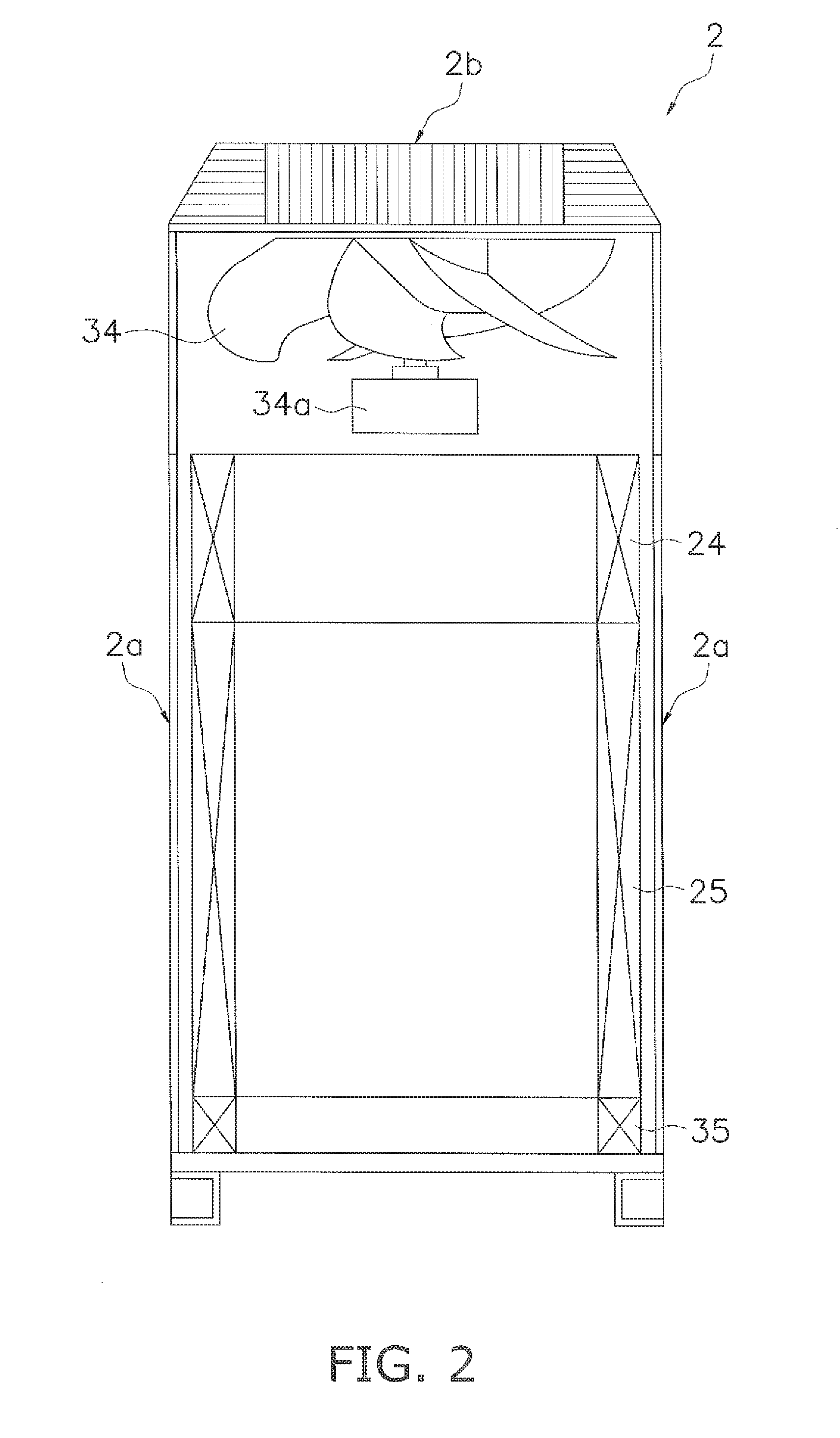

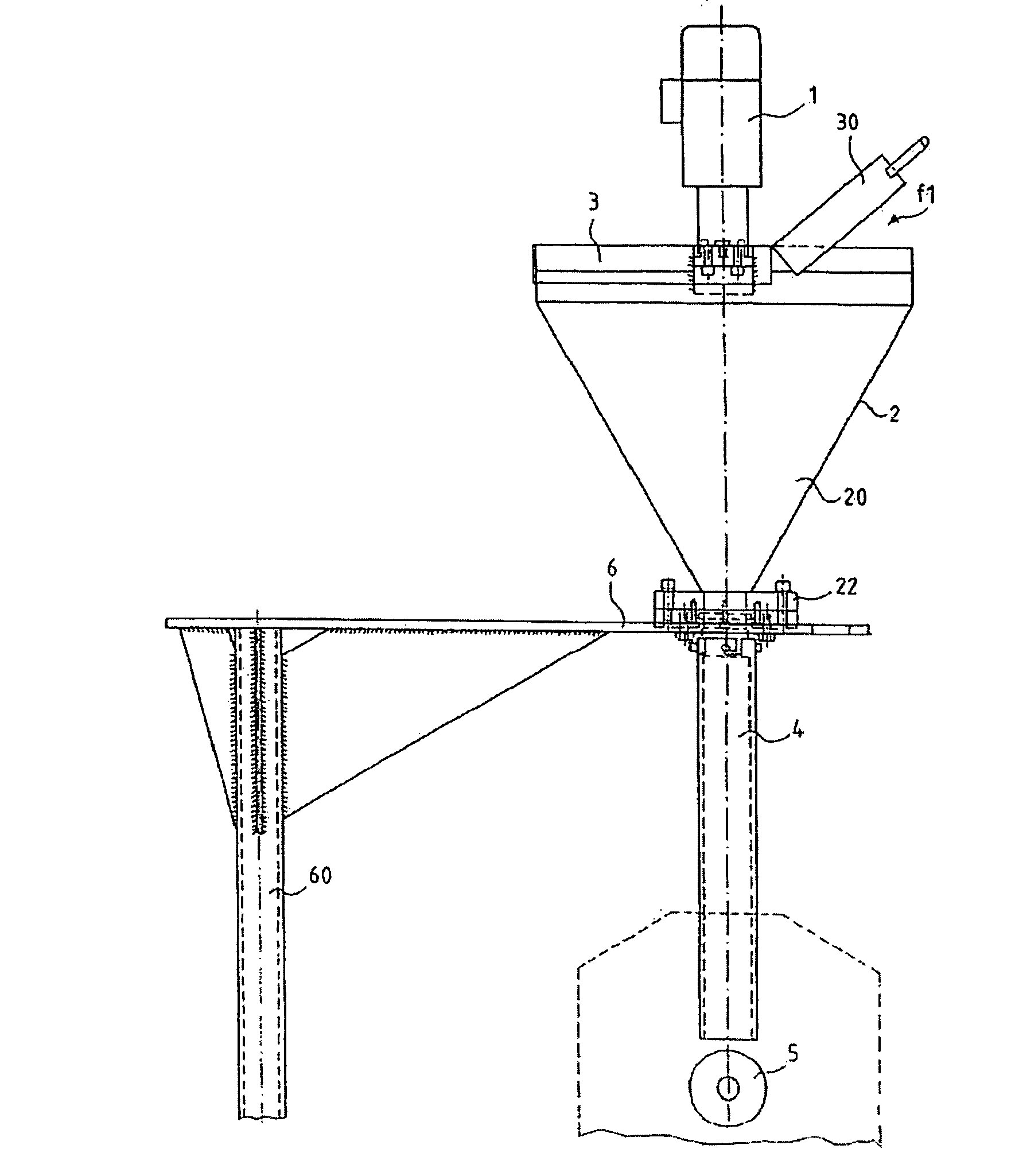

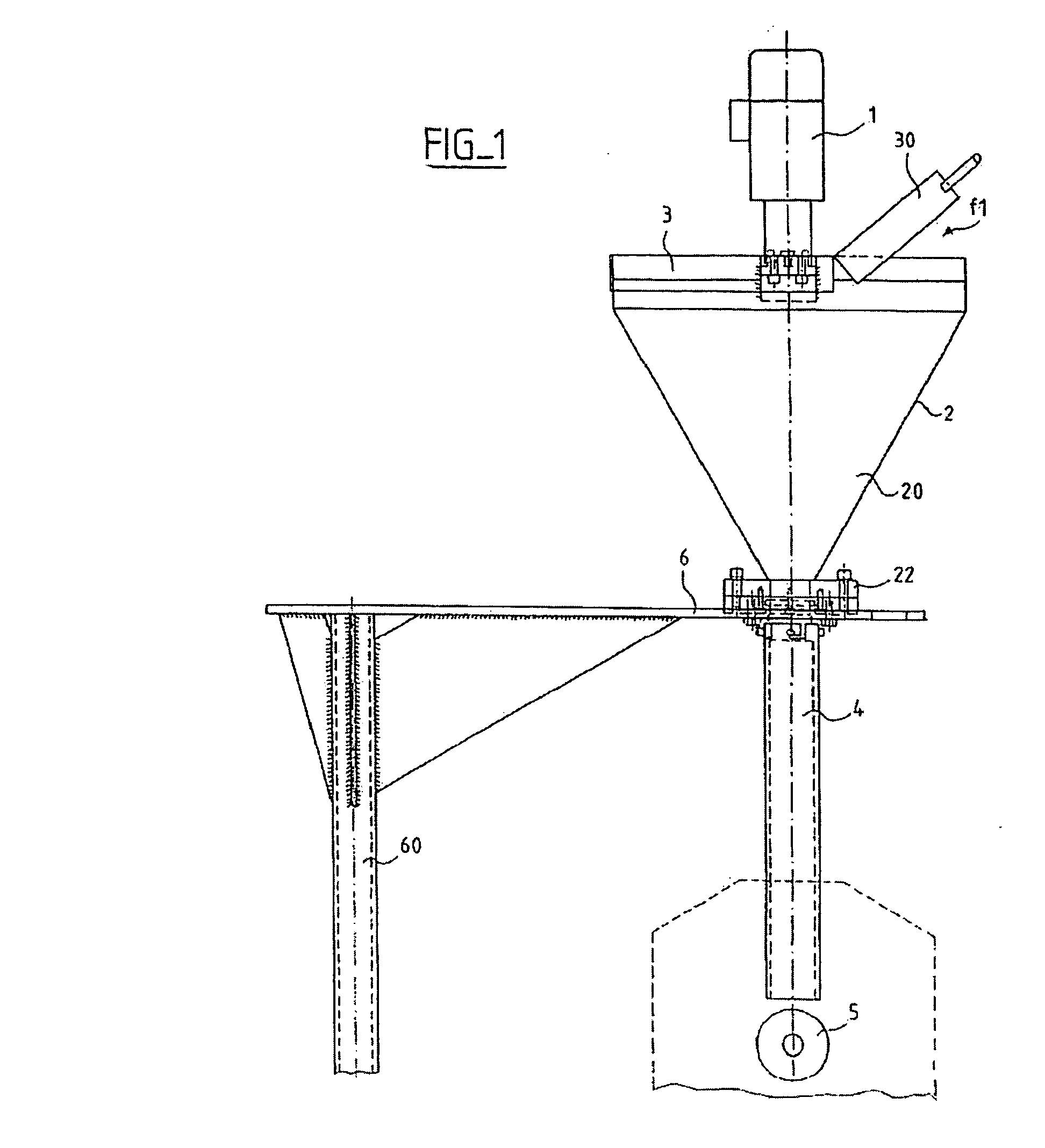

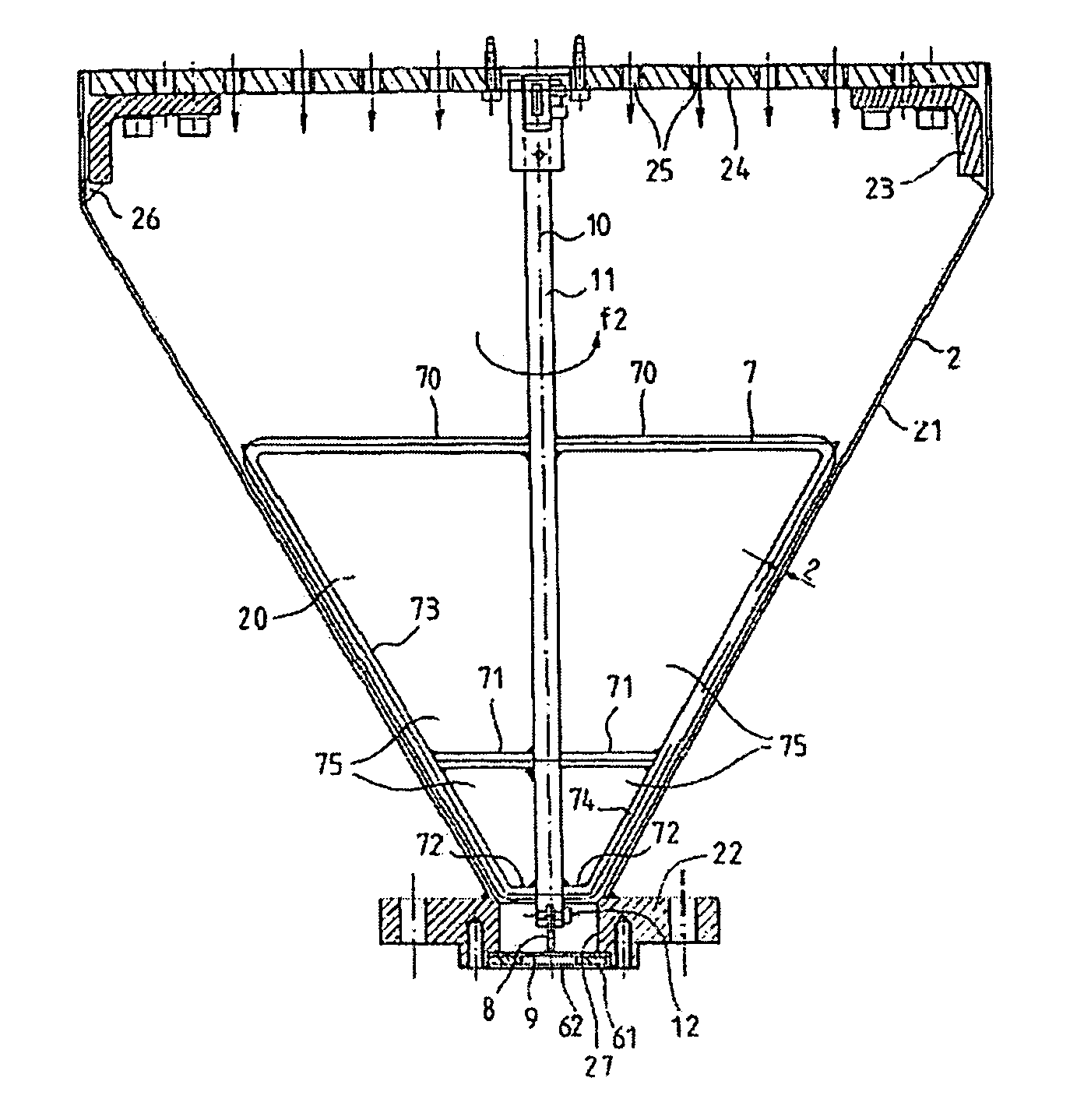

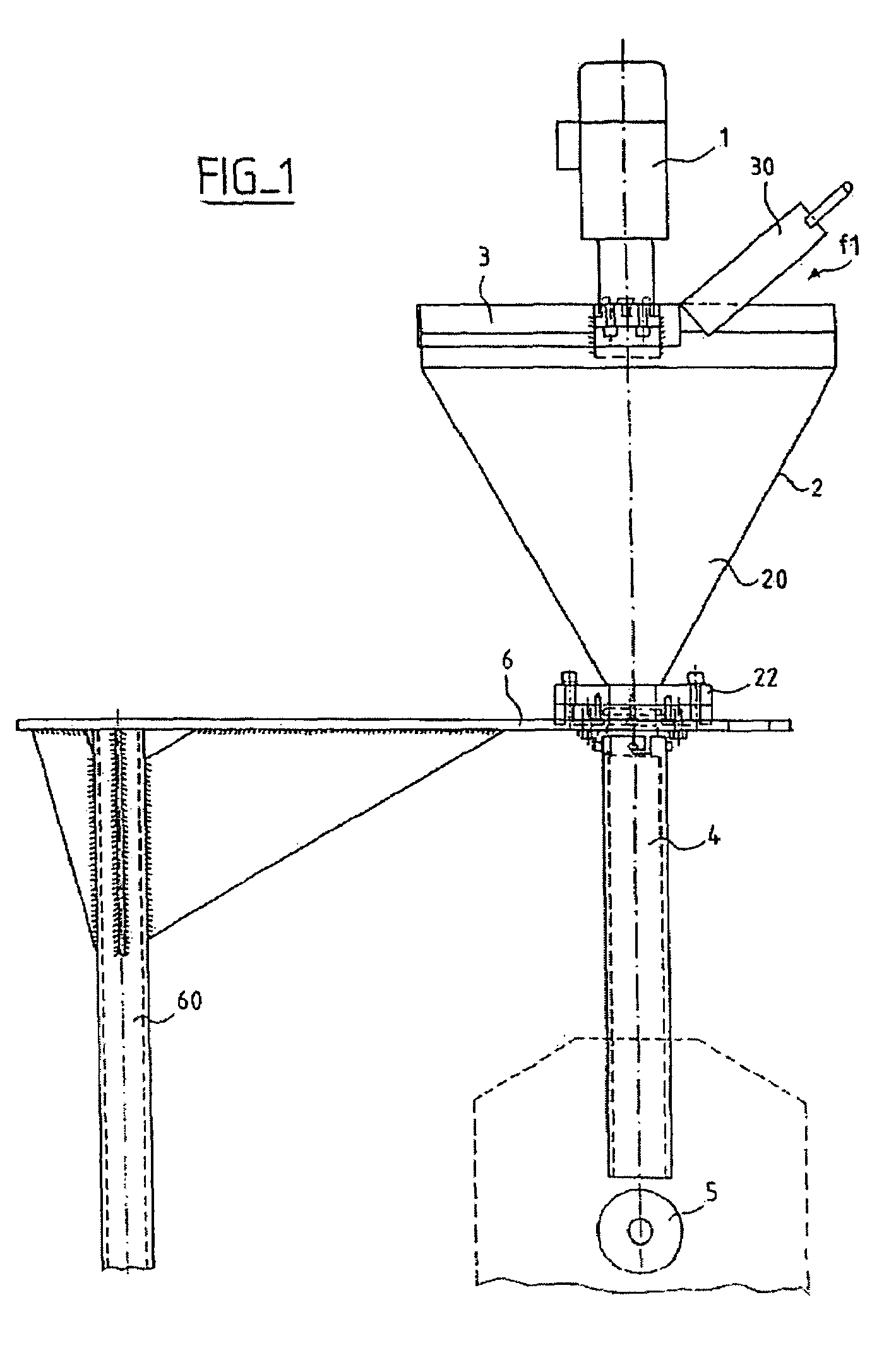

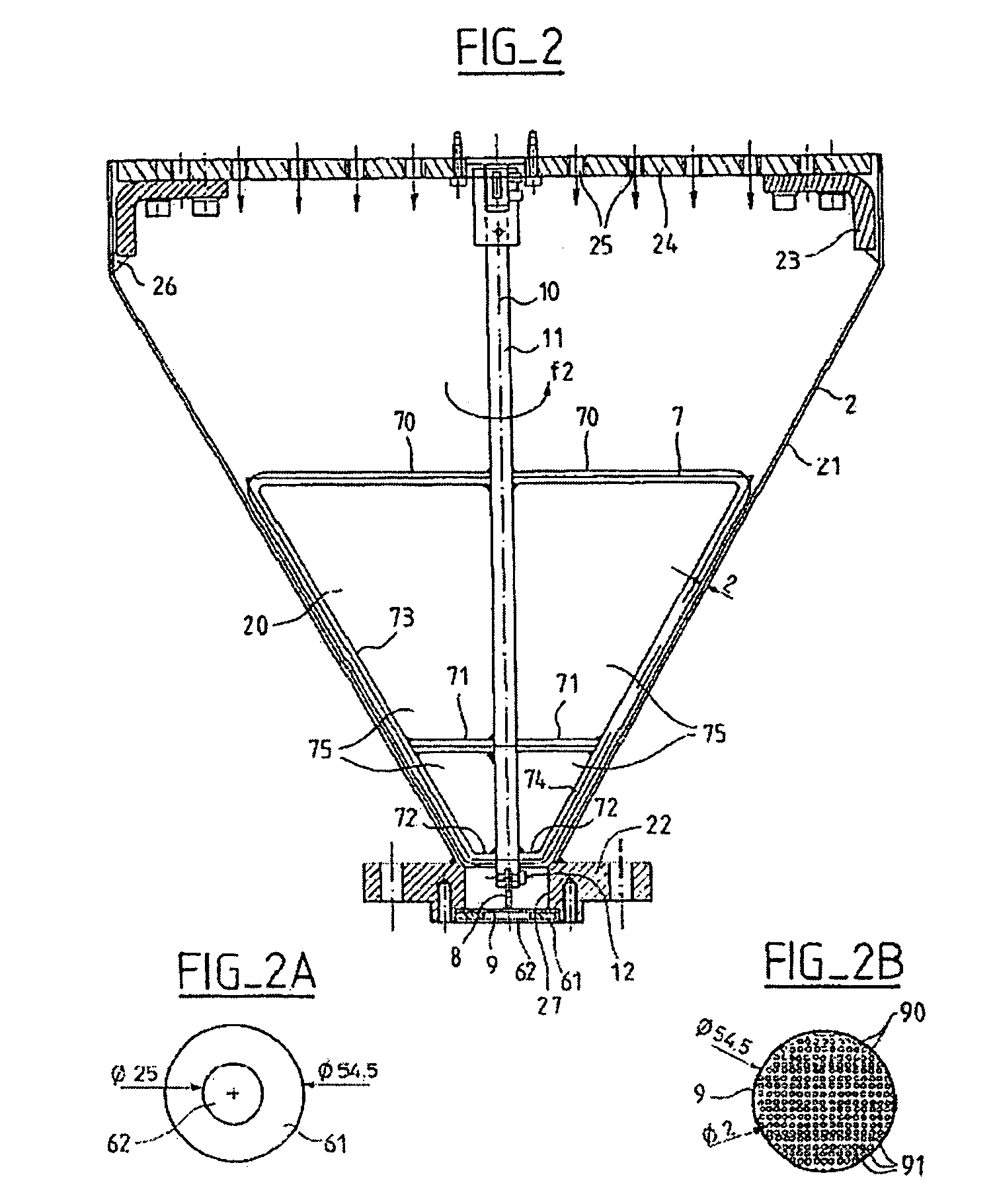

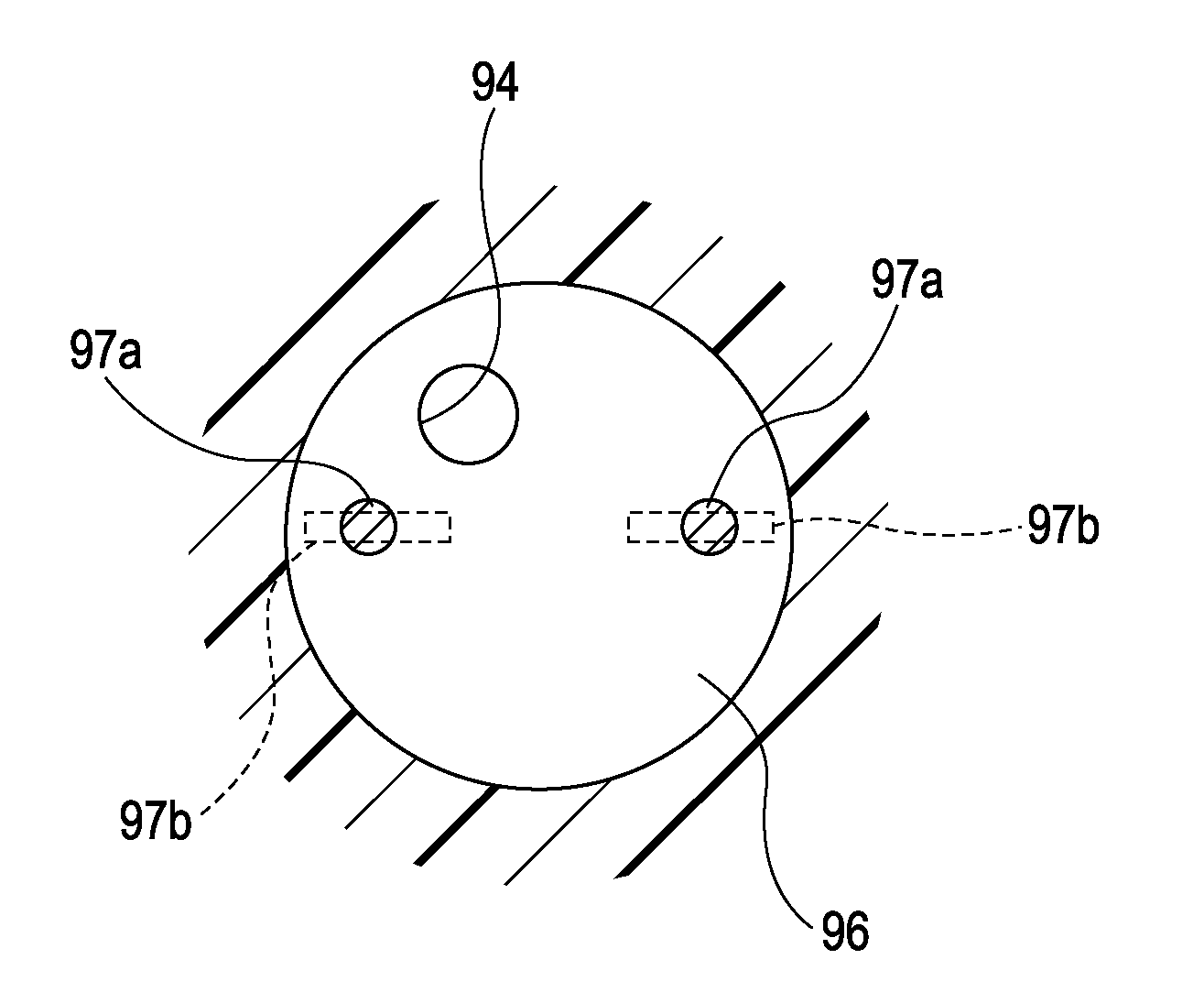

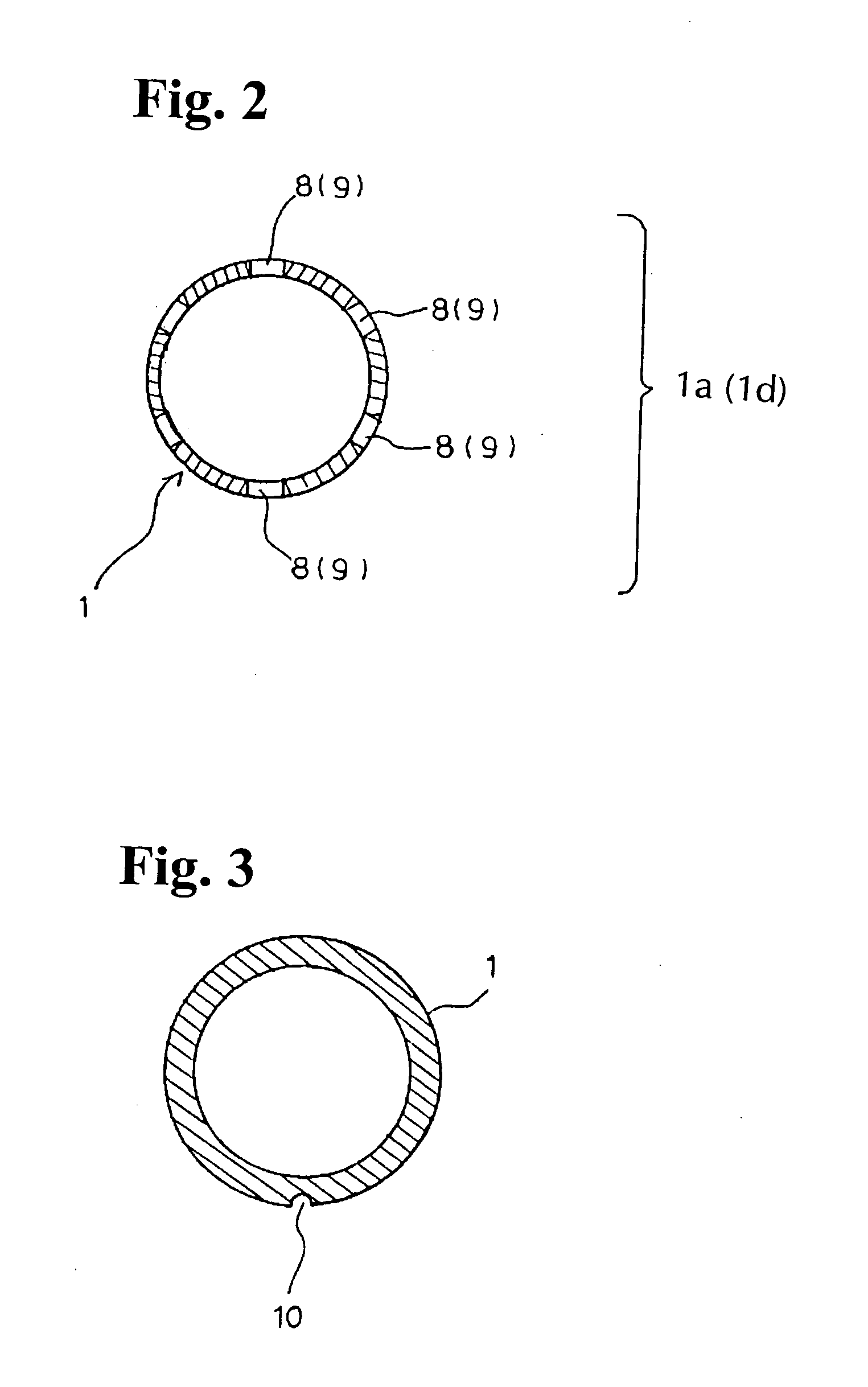

Cable powder applicator

InactiveUS20050045098A1Easy passBlock fluid flowLiquid surface applicatorsFibre mechanical structuresFiberEngineering

The invention relates to the field of applicators for applying moisture-absorbent powder on cable elements. This is an applicator for applying moisture-absorbent powder on cable elements which comprises a hopper intended to contain the powder, a mesh closing the small opening of the hopper and a mechanical powder stirrer located inside the hopper, the stirrer being placed in the hopper in such a way as to be able to make the powder flow through the mesh under gravity, the applicator having no means for conveying the powder that has passed through the mesh, which powder continues to flow under gravity as far as the cable elements. The type of cable in question is in particular a fiber-optic cable.

Owner:DRAKA COMTEQ BV

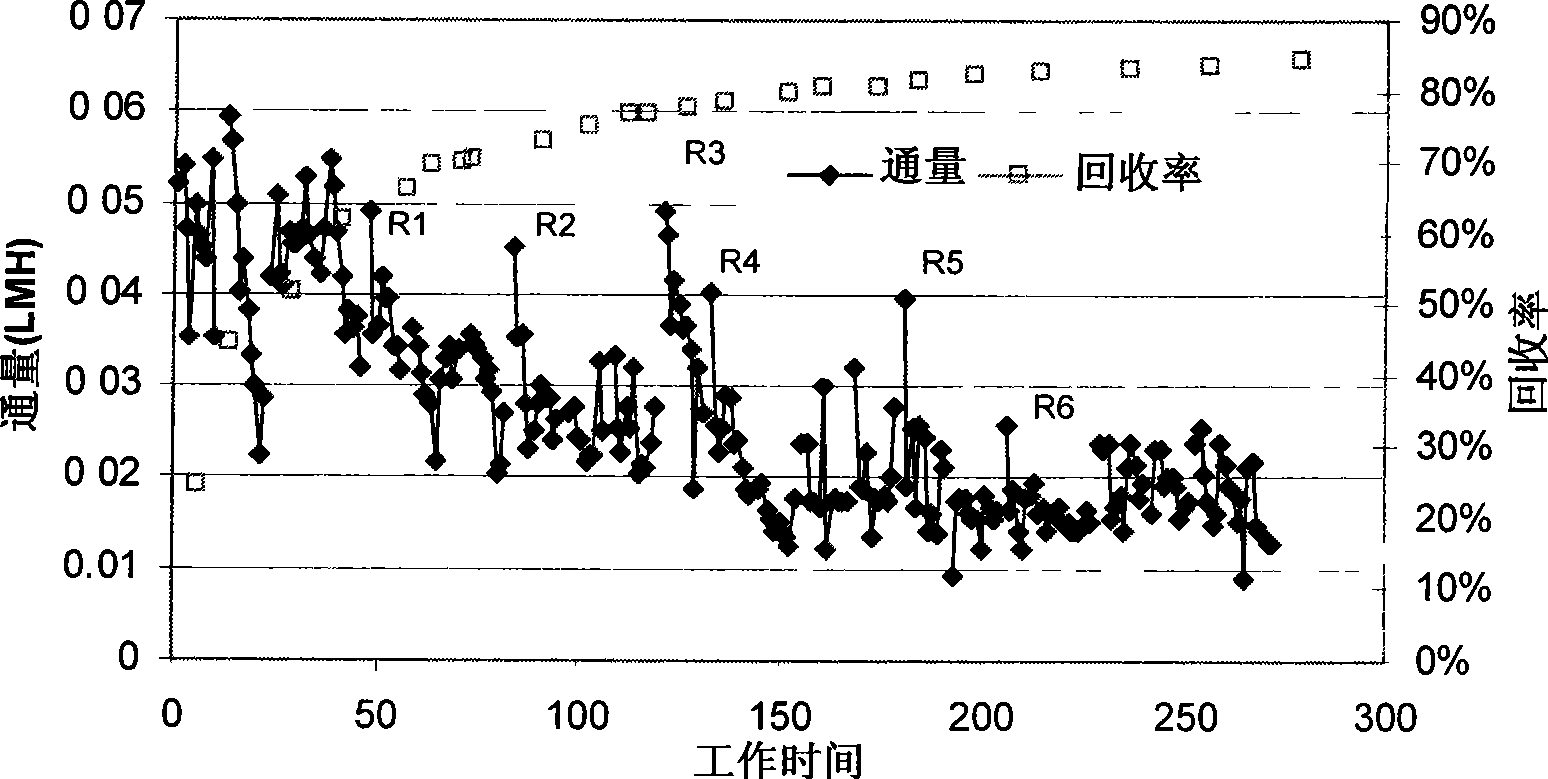

Method for removing pollutant in oil

InactiveCN101434858AHigh film convergence rateOffsets low-throughput drawbacksRefining by filtrationHydrophobic polymerChemistry

The invention discloses a method for removing pollutant in oil, which comprises procedures of: making oil raw material pass through permeable hydrophobic polymer film. Oil passing through the film has fewer pollutants relative to the oil raw material.

Owner:HYFLUX LTD

Cable powder applicator

InactiveUS7323057B2Easy to moveMaintain flow rateLiquid surface applicatorsFibre mechanical structuresFiberEngineering

The invention relates to the field of applicators for applying moisture-absorbent powder on cable elements. This is an applicator for applying moisture-absorbent powder on cable elements which comprises a hopper intended to contain the powder, a mesh closing the small opening of the hopper and a mechanical powder stirrer located inside the hopper, the stirrer being placed in the hopper in such a way as to be able to make the powder flow through the mesh under gravity, the applicator having no means for conveying the powder that has passed through the mesh, which powder continues to flow under gravity as far as the cable elements. The type of cable in question is in particular a fiber-optic cable.

Owner:DRAKA COMTEQ BV

Heat-recovery-type refrigerating apparatus

A heat-recovery-type refrigerating apparatus includes a compressor, a heat-source-side heat exchanger, and a plurality of usage-side heat exchangers, and refrigerant is sent from the usage-side heat exchanger functioning as a refrigerant radiator to the usage-side heat exchanger functioning as a refrigerant evaporator, whereby heat can be recovered between the usage-side heat exchangers. Here, a portion of the heat-source-side heat exchanger is configured as a precooling heat exchanger for always circulating high-pressure vapor refrigerant discharged from the compressor, and a refrigerant cooler for cooling an electrical equipment item is connected to a downstream side of the precooling heat exchanger.

Owner:DAIKIN IND LTD

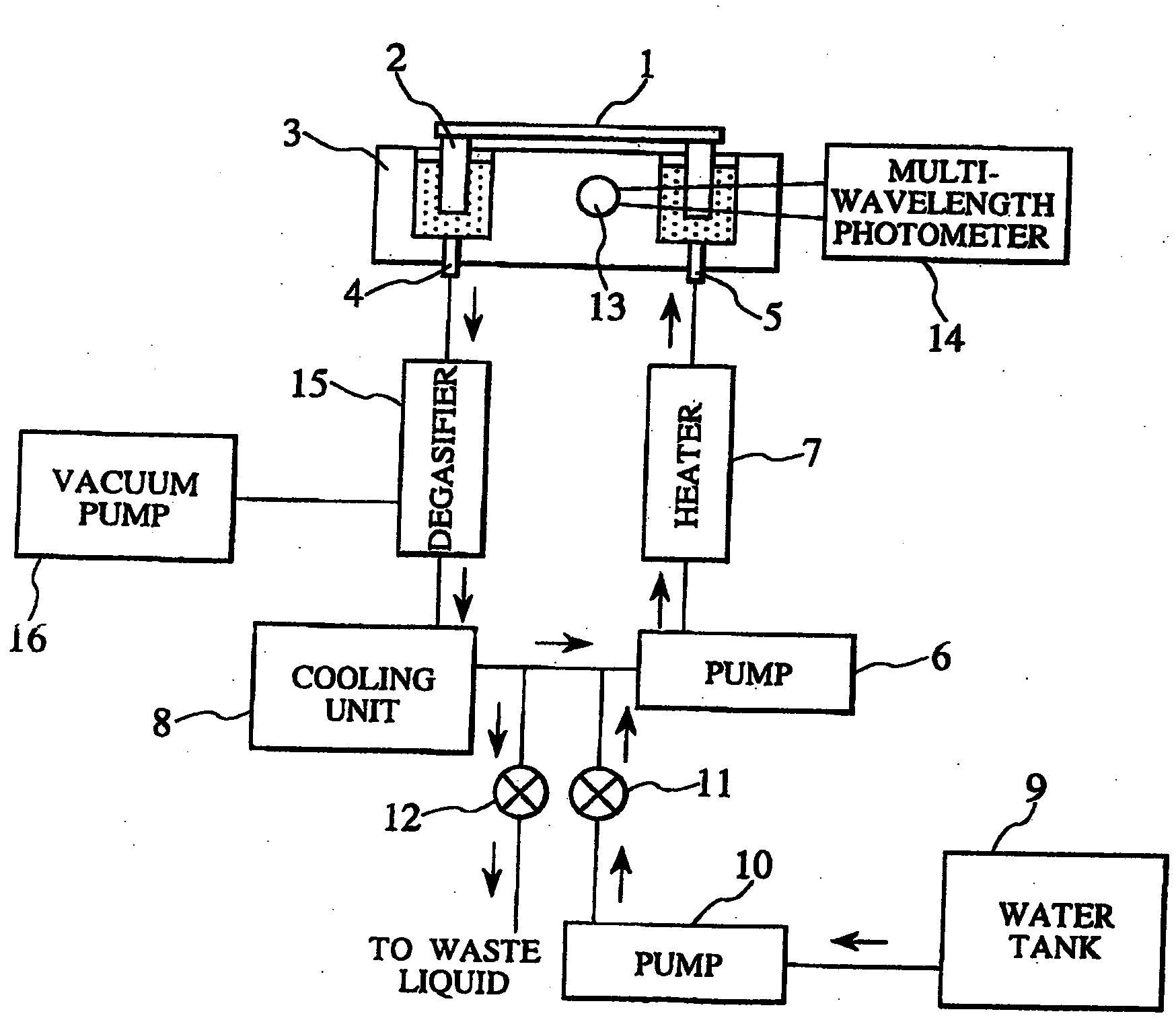

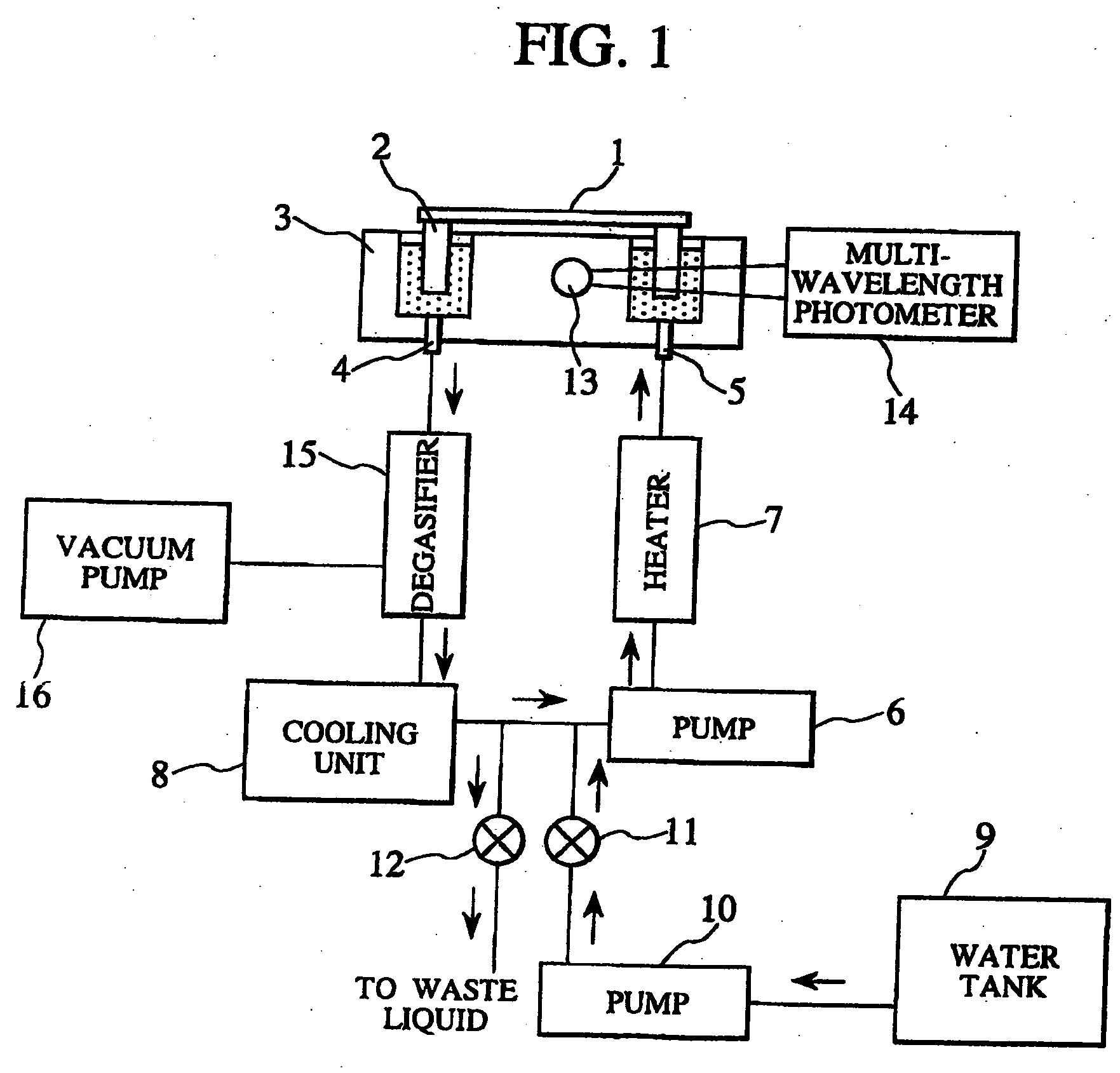

Automatic analyzer

InactiveUS20090220383A1Reduce generationStable photometryBiological testingChemical/physical/physico-chemical processesTemperature controlLight flux

Disclosed herein is an automatic analyzer that can eliminate the generation of air bubbles of dissolved gas in a liquid circulating in a thermostat bath enabling stable photometry.A degasifier for removing the dissolved gas in the liquid and a bypass passage for ensuring a flow rate required for temperature control of the circulating liquid are provided in a passage for temperature-controlled liquid circulating in the thermostat bath. The automatic analyzer can reduce the dissolved gas concentration to a level at which air bubbles of the dissolved gas in the liquid do not appear while maintaining a flow rate required for temperature control of the liquid circulating in the thermostat bath, thus eliminating air bubbles passing through the light flux during photometry and accordingly enabling stable photometry.

Owner:HITACHI HIGH-TECH CORP

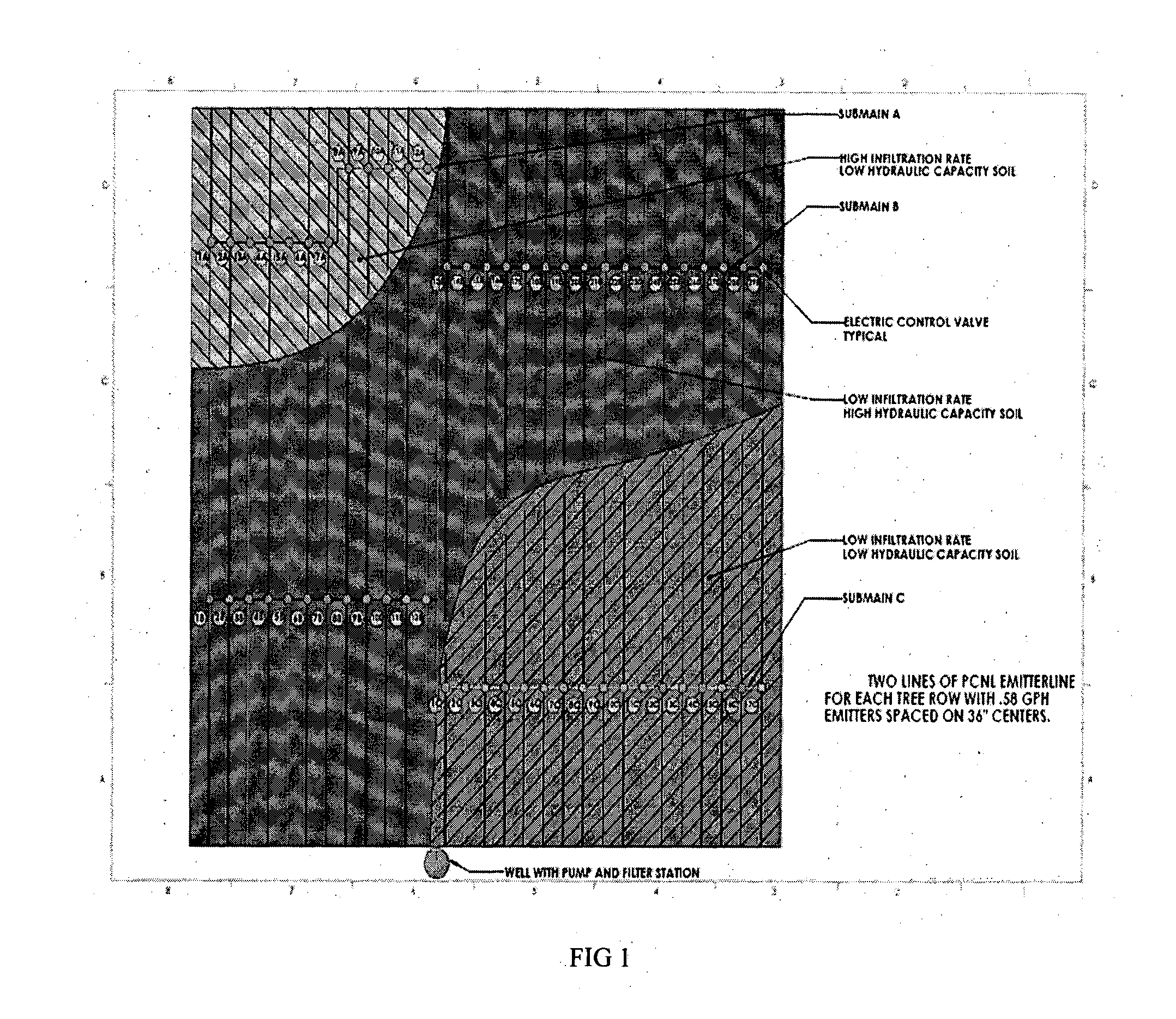

Modulated cyclic flow (MCF) drip irrigation systems

InactiveUS20140312134A1Easy to irrigateUse minimizedSelf-acting watering devicesClimate change adaptationStart timeDrip irrigation

The present system comprises, a MFC controller, emitter-lines that utilize non-drain technology on the emission devices and control valves for individual drip lines or groups of drip lines within an irrigation zone, along with a means to actuate the control valves by the controller. The MCF system utilizes a number of valves in an irrigation system to control either individual emitter-lines or groups of emitter-lines but does not control individual emitters. The present system has a programmable controller that has a number of stations, each of which controls a group of valves. Each station can be programmed for start time and duration that the station is actuated. Each station can be programmed independently from all the others allowing overlap or complimentary irrigation. The total input flow rate to the system remains nearly constant during a daily irrigation while the valve groups are cycling within the system.

Owner:JAIN IRRIGATION SYSTEMS LIMITED

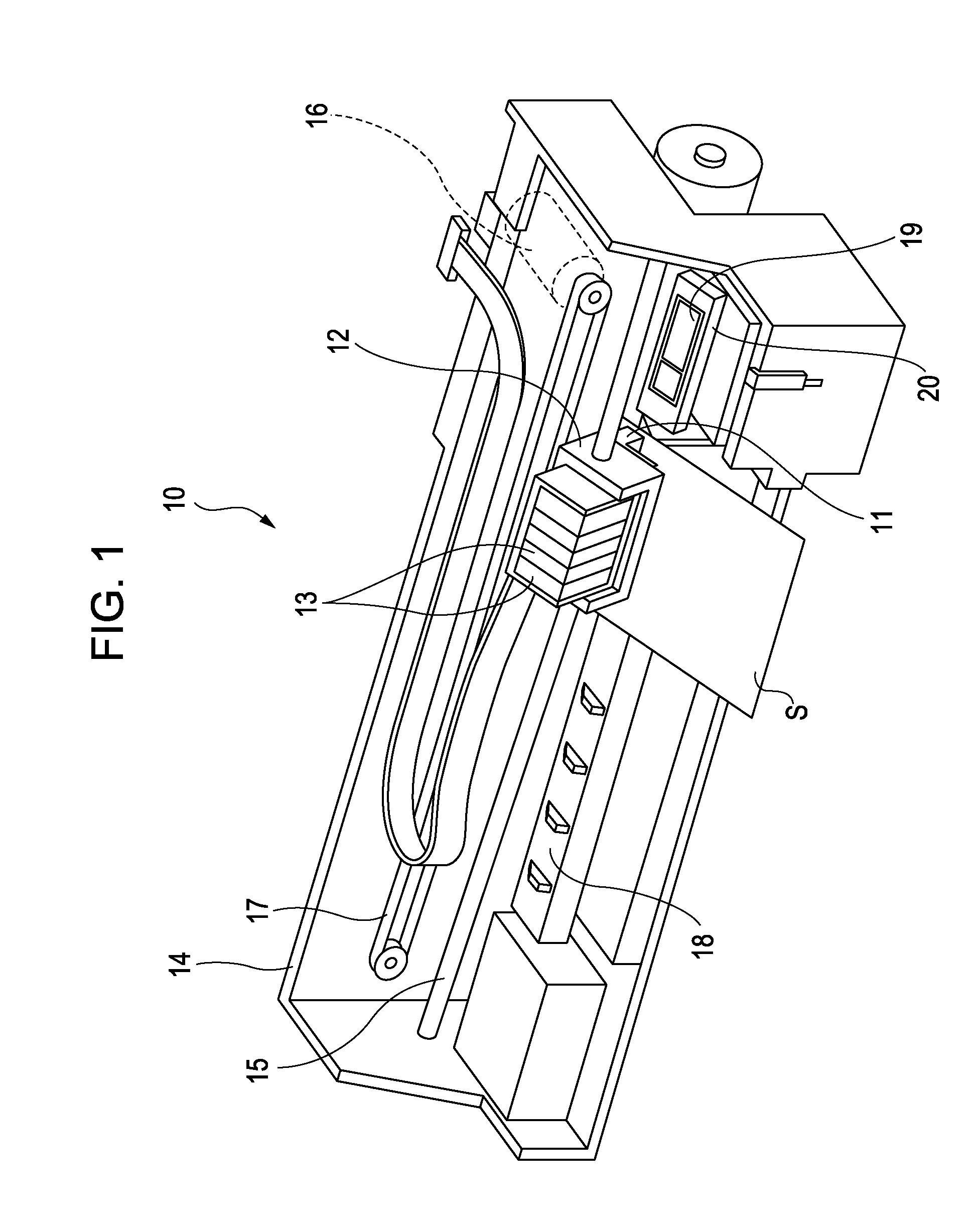

Parallel Belt Sampler

InactiveUS20130047750A1Lower speedReduce speedWithdrawing sample devicesConveyor partsMaterial transferEngineering

Apparatus for sampling material being conveyed on a primary conveyor comprises a diverter arranged to divert material onto a sampling conveyor running alongside the primary conveyor where it can be weighed by a weightometer and elevated to a discharge point before falling into a falling-stream sample cutter. Material is then returned to the primary conveyor at by a return conveyor. Options include the use of an impact conveyor between the diverter and the sampling conveyor, and the configuration of the sampling conveyor with a wider belt running at a slower speed to improve accuracy.

Owner:NEWCASTE INNOVATION LTD

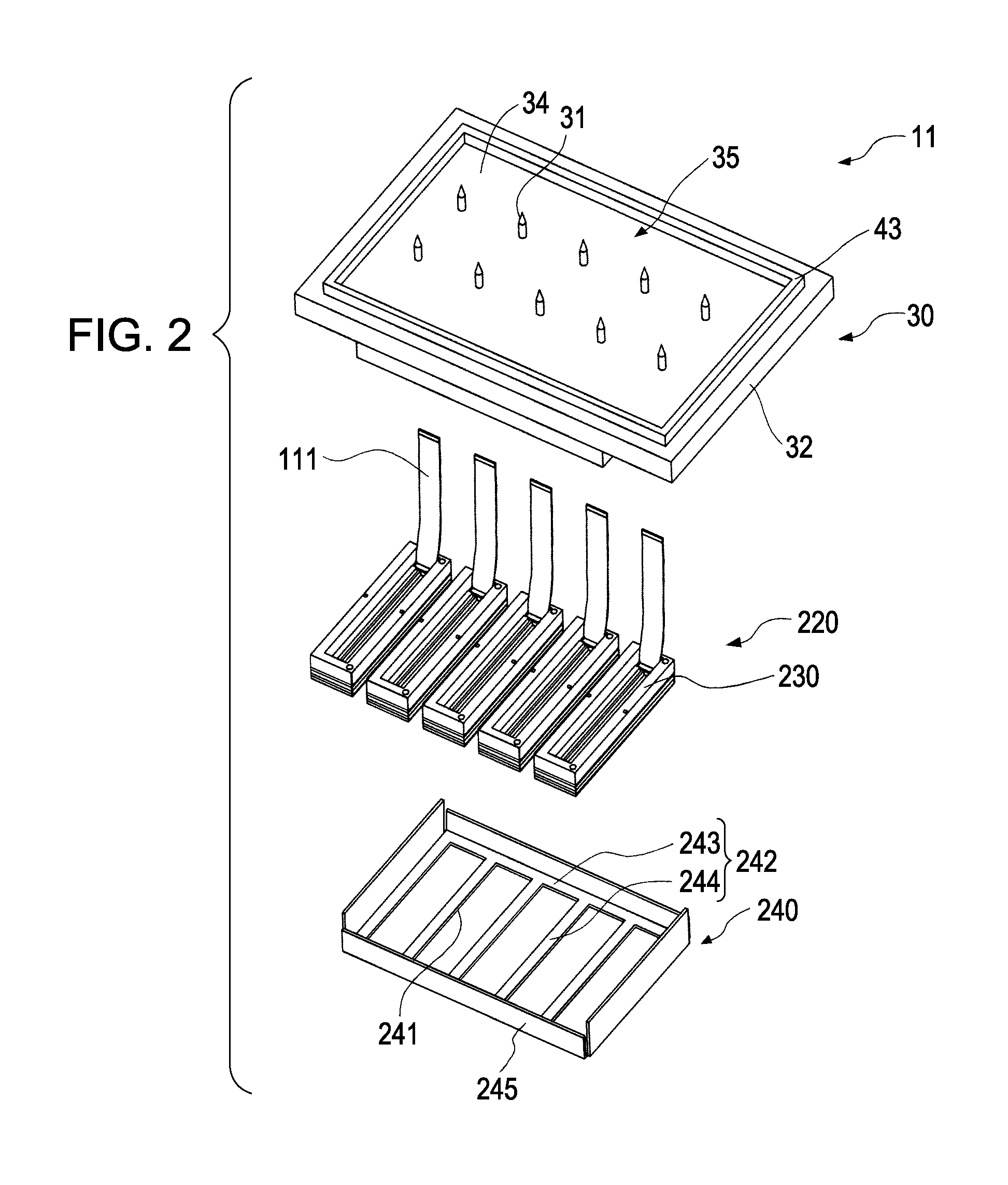

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20110228021A1Suppress degradation of bubble dischargingPrevent degradationPrintingLiquid jetEngineering

Owner:SEIKO EPSON CORP

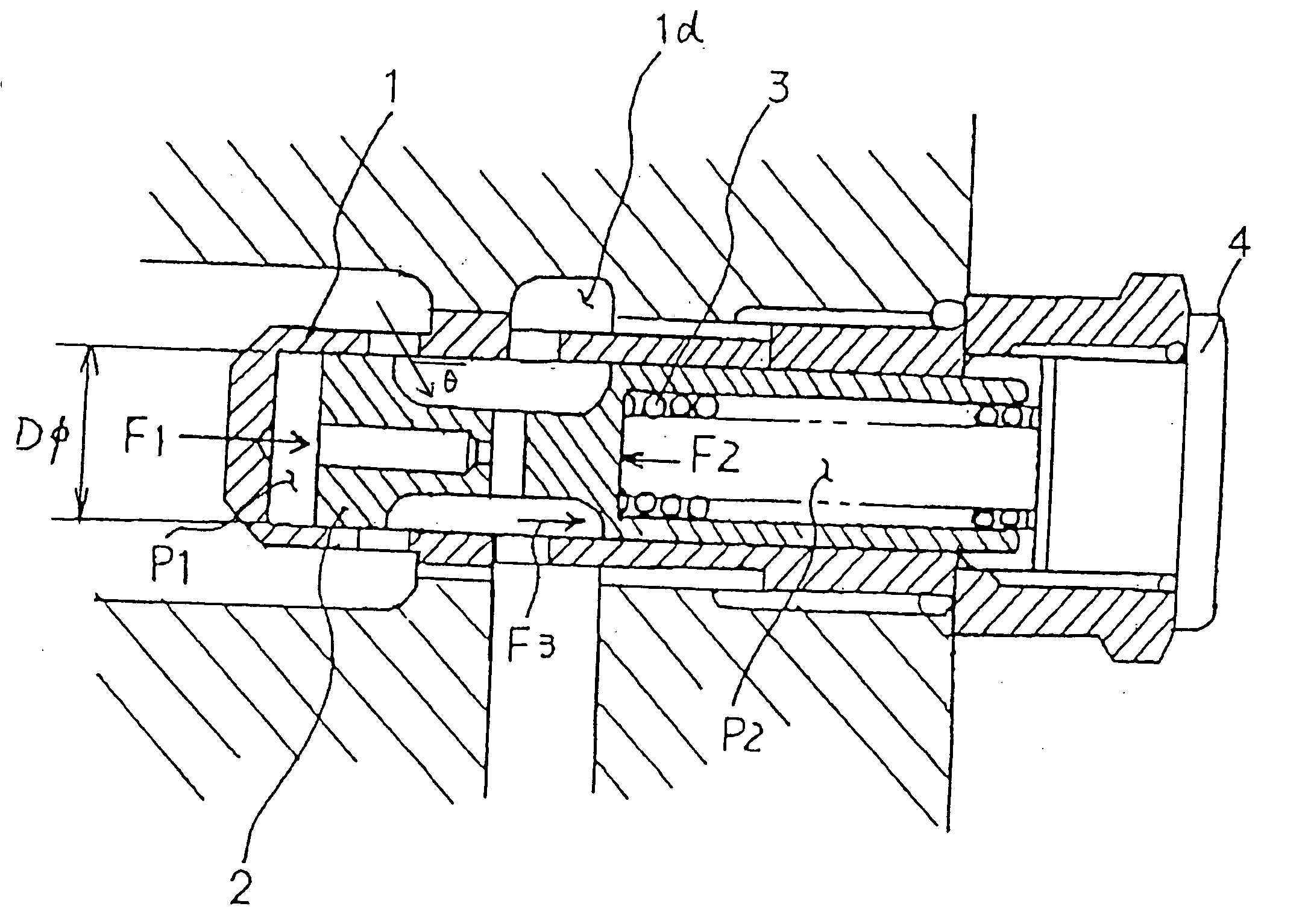

Flow control valve

ActiveUS20040107998A1Maintain flow rateOperating means/releasing devices for valvesEqualizing valvesEngineeringControl valves

In a flow control valve, a spool is fitted into a cylindrical body including an input port and an output port. A spring is disposed between the spool and a flow rate setting plug at an end of the cylindrical body. A flow by-path communicating with the input port and the output port is provided on an outer peripheral portion of the cylindrical body. When a quantity of a fluid flowing through the flow control valve is reduced, the fluid flowing through the flow by-path compensates the reduction thereof. Accordingly, it is possible to maintain a constant flow rate.

Owner:SHIMADZU CORP

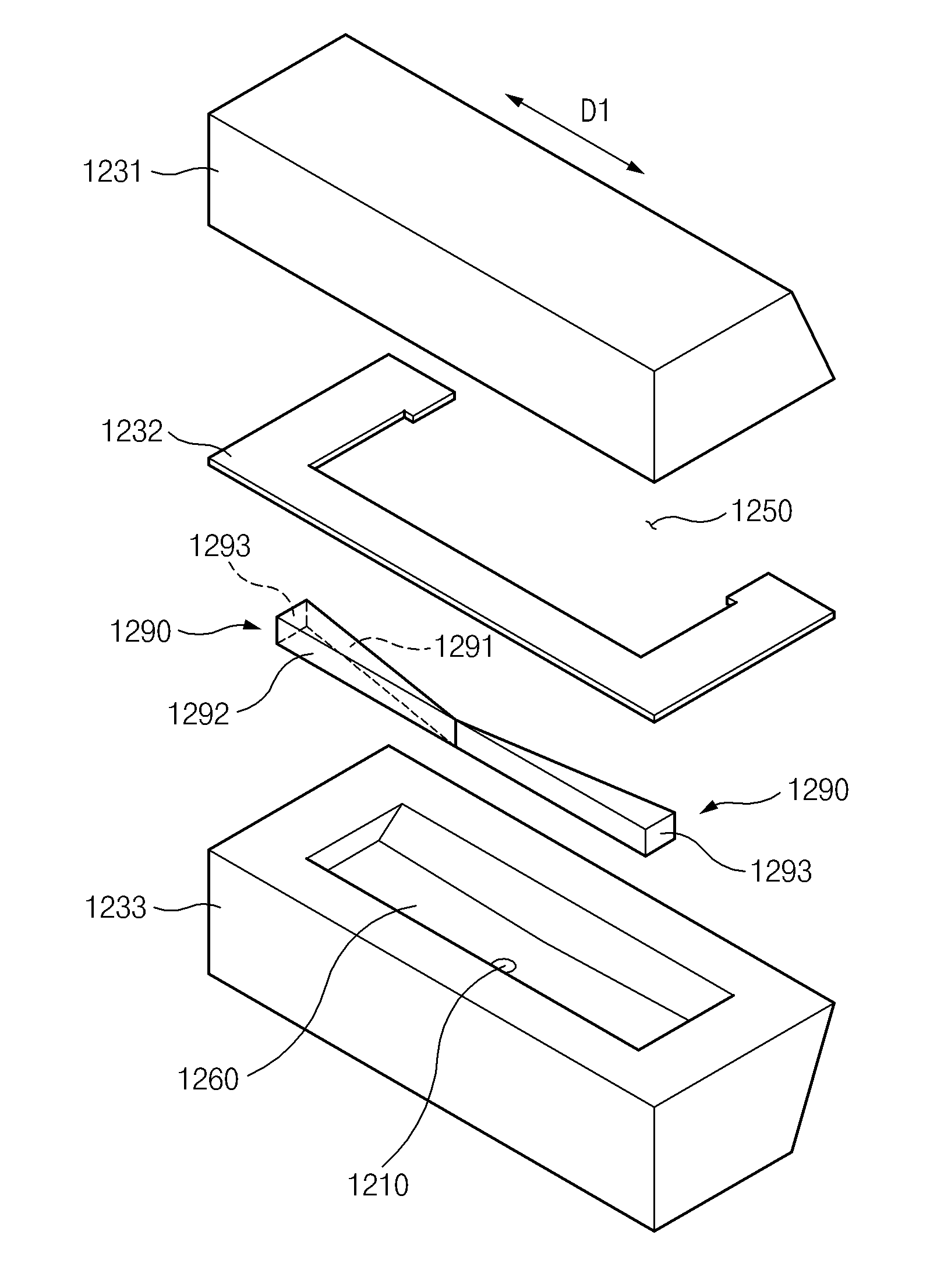

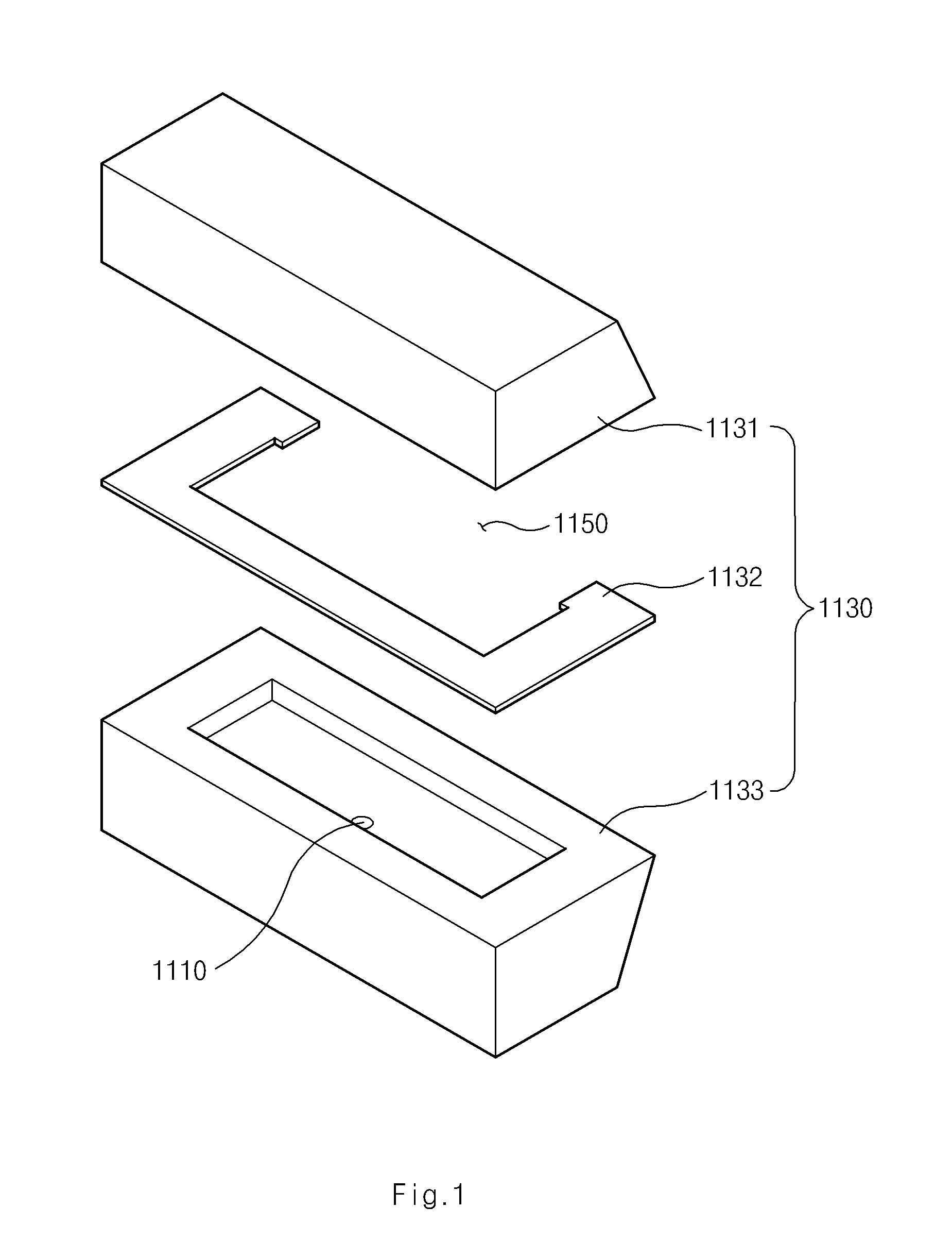

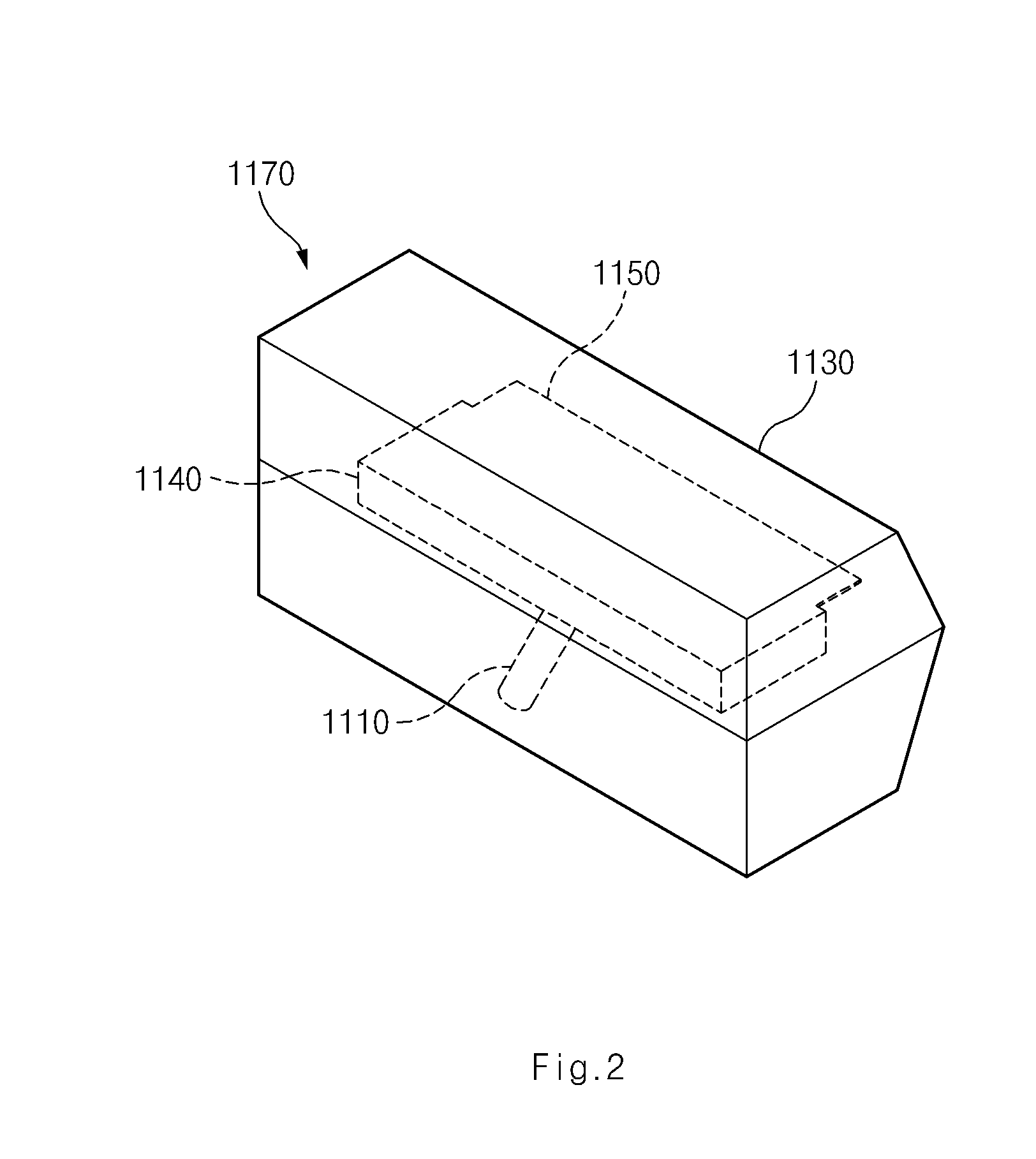

Member for slot die coater, movable member for slot die coater, and slot die coater including the members to produce electrode

ActiveUS20150053133A1Reduce coating defectsMaintain flow rateLiquid surface applicatorsElectrode manufacturing processesMetal foilEngineering

Provided is a slot die coater that applies electrode slurry to metal foil to produce an electrode, the slot die coater including a die part, which includes a body having an inner space receiving the electrode slurry, a supply hole disposed in the body to supply the electrode slurry to the inner space, and a discharge hole disposed in the body to discharge the electrode slurry from the inner space to the metal foil, and a member for the slot die coater, which is removably installed in the inner space to form a slope surface in the inner space, or a movable member for the slot die coater, which selectively forms the slope surface.

Owner:LG ENERGY SOLUTION LTD

Compensation for unmeasurable inspiratory flow in a critical care ventilator

ActiveUS9358356B2Reduce flow rateReduce trafficRespiratorsMedical atomisersNebulizerInspiratory flow

A system and method for operating a ventilator to compensate for external gas flow reaching a patient from an external device, such as a nebulizer. A control unit of the ventilator monitors the gas flow rate from the ventilator and compares the gas flow rate from the ventilator to an expired gas flow rate from the patient. The difference between the inspired flow rate and the expired flow rate is due to the external device. The control unit modifies the operation of the ventilator to compensate for the external gas flow rate such that the flow of gas reaching the patient is maintained at a desired level.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com