Fluid supply device

a technology of fluid supply device and fluid supply device, which is applied in the direction of positive displacement liquid engine, electric control, machine/engine, etc., can solve the problems of large size, large size of fluid supply device, and supply device with electric motor driven pump, etc., to achieve the effect of reducing the size and cost of the fluid supply device, reducing the size and cost, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

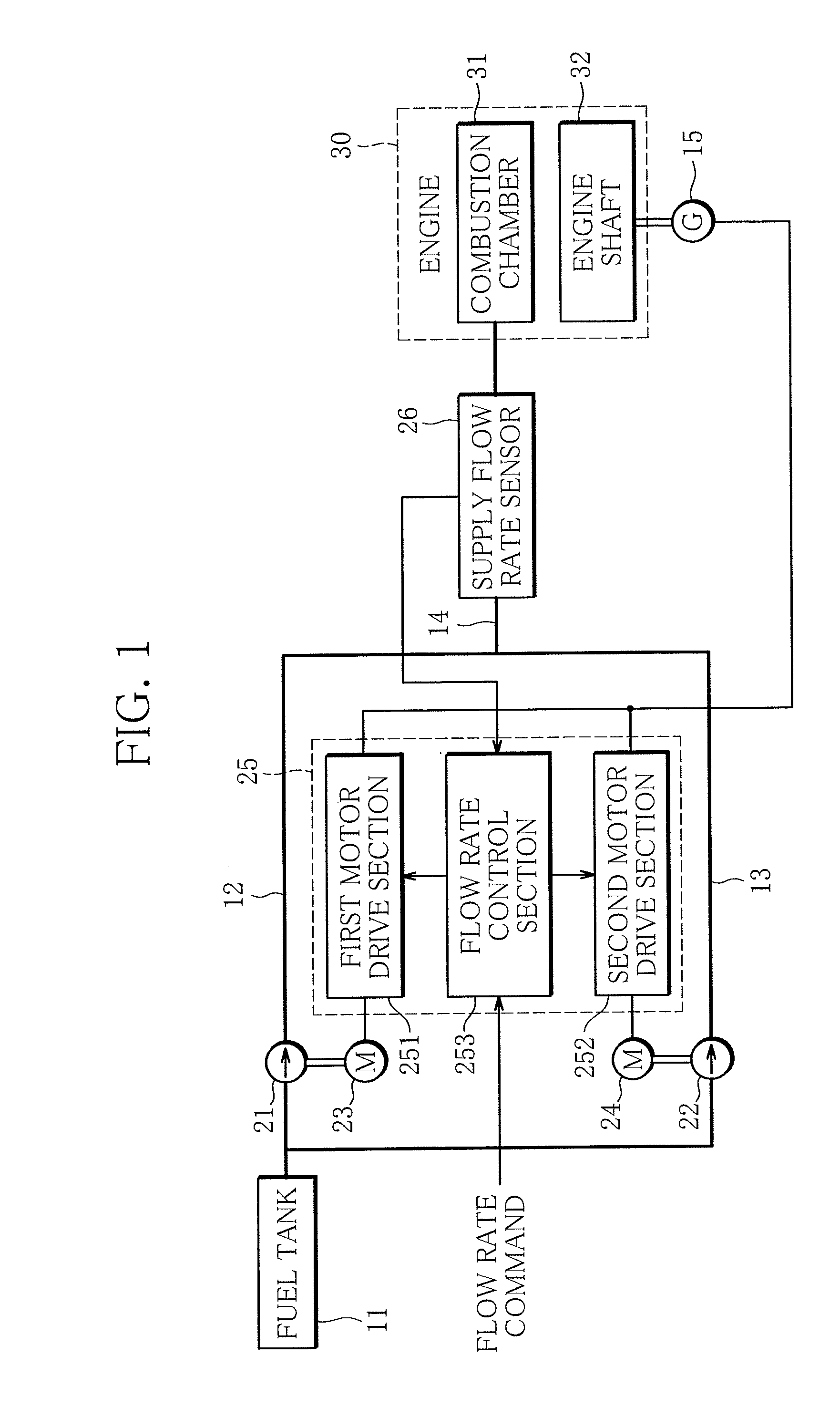

[0027]With reference to FIG. 1, a first embodiment of a fluid supply device, specifically, fuel supply device according to the present invention will be described.

[0028]FIG. 1 is a block diagram showing the configuration of the first embodiment of the fuel supply device.

[0029]The first embodiment of the fuel supply device comprises a fuel tank 11, a first fuel passage 12, a second fuel passage 13, a supply passage 14, an electric generator 15, a first fuel pump 21, a second fuel pump 22, a first electric motor 23, a second electric motor 24, a control device 25 and a supply flow rate sensor 26.

[0030]The fuel tank 11, which is a “reservoir”, holds fuel, which is “fluid”. To the fuel tank 11, the first and second fuel passages 12, 13 are connected. The first and second fuel passages 12, 13 are connected to the supply passage 14 at the other end. The supply passage 14 is connected to a combustion chamber 31 of an engine 30. The engine 30 is an internal combustion engine operating by bu...

second embodiment

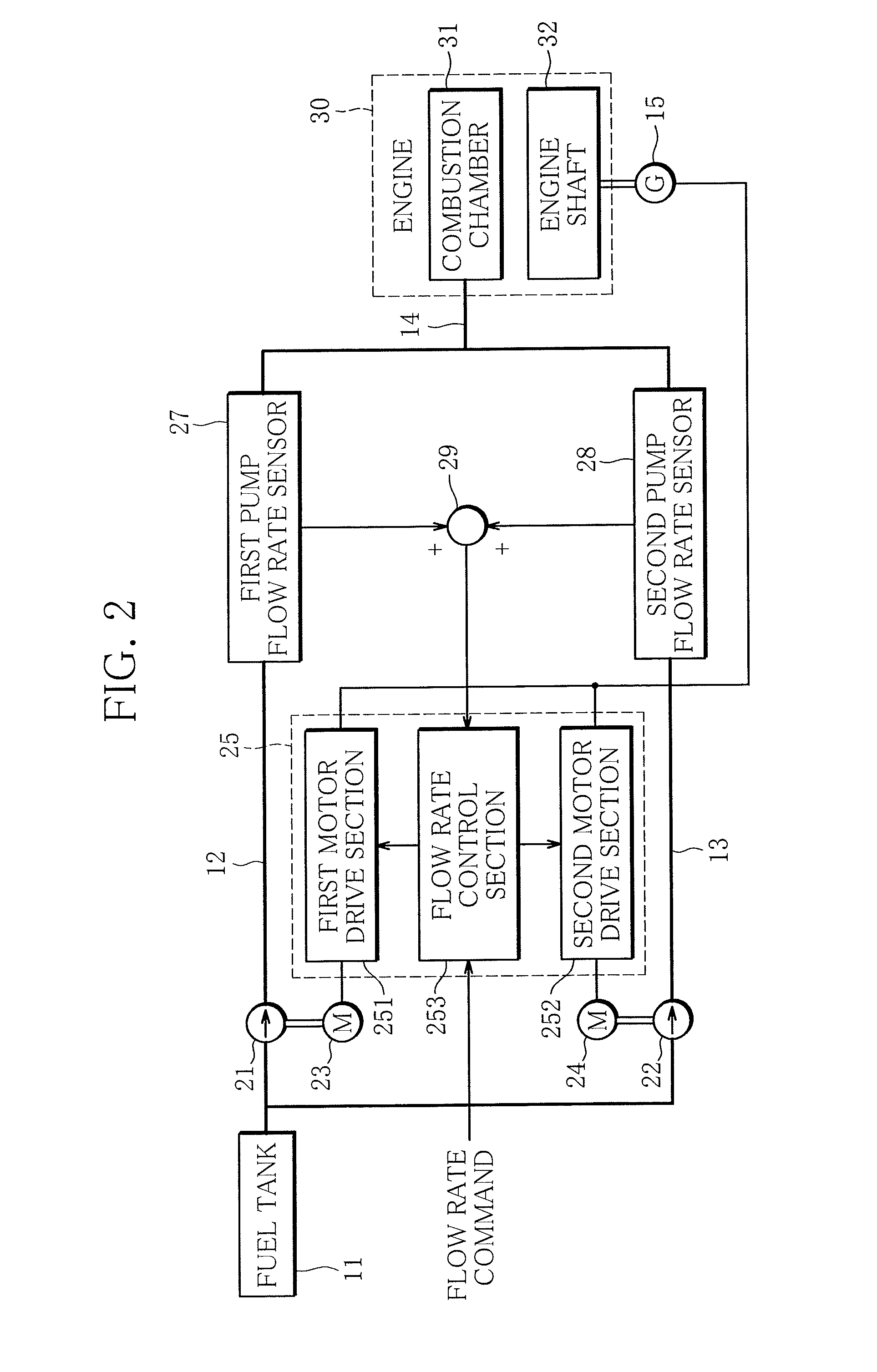

[0041]With reference to FIG. 2, a second embodiment of the fluid supply device, specifically, fuel supply device according to the present invention will be described.

[0042]FIG. 2 is a block diagram showing the configuration of the second embodiment of the fuel supply device.

[0043]The second embodiment of the fuel supply device differs from the first embodiment in that it comprises a first pump flow rate sensor 27, a second pump flow rate sensor 28 and an adder 29 in place of the supply flow sensor 26 of the first embodiment; both embodiments are similar in the other respects. In the following description of the second embodiment, the differences from the first embodiment will be described in detail while the same components as those of the first embodiment, indicated by the same reference characters, will not.

[0044]In the second embodiment, the “flow rate detection device” comprises a first pump flow rate sensor 27, a second pump flow rate sensor 28 and an adder 29. The first pump f...

third embodiment

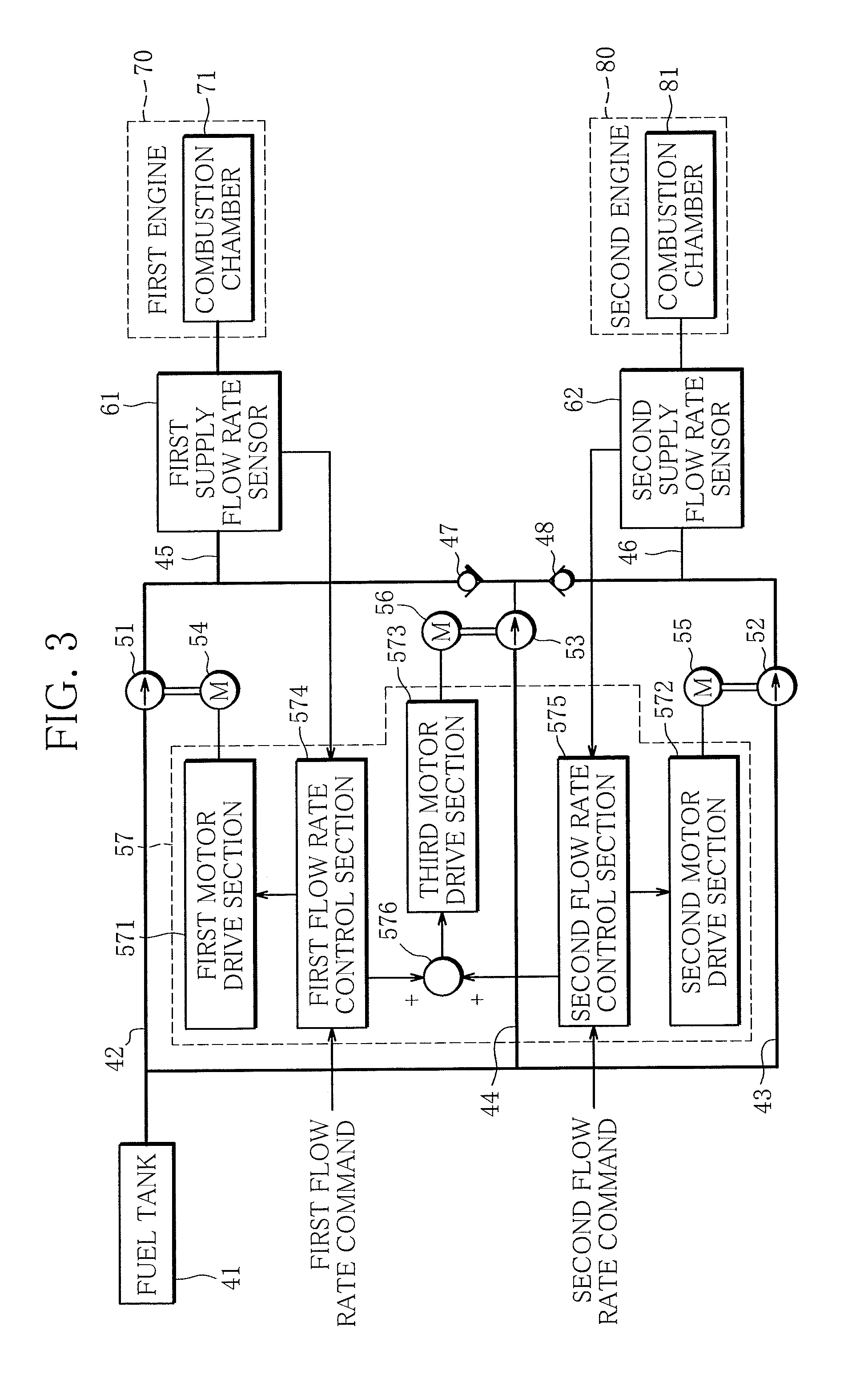

[0046]With reference to FIG. 3, a third embodiment of the fluid supply device, specifically, fuel supply device according to the present invention will be described.

[0047]FIG. 3 is a block diagram showing the configuration of the third embodiment of the fuel supply device.

[0048]The third embodiment of the fuel supply device comprises a fuel tank 41, a first fuel passage 42, a second fuel passage 43, a third fuel passage 44, a first supply passage 45, a second supply passage 46, a first check valve 47 and a second check valve 48.

[0049]The fuel tank 41, which is a “reservoir”, holds fuel, which is “fluid”. To the fuel tank 41, the first, second and third fuel passage 42, 43, 44 are connected. The first fuel passage 42 is connected to the first supply passage 45, the second fuel passage 43 to the second supply passage 46, and the third fuel passage 44 to both the first and second supply passages 45, 46. The first check valve 47 is fitted to a passage between the third fuel passage 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com