Lightning arrestor mounting base

A technology for lightning arresters and mounting bases, which is applied in the direction of overvoltage protection resistors and varistors, etc., can solve the problems of inconvenient operation of lightning arrester tests, and achieve the effects of avoiding complicated work links, improving labor efficiency, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

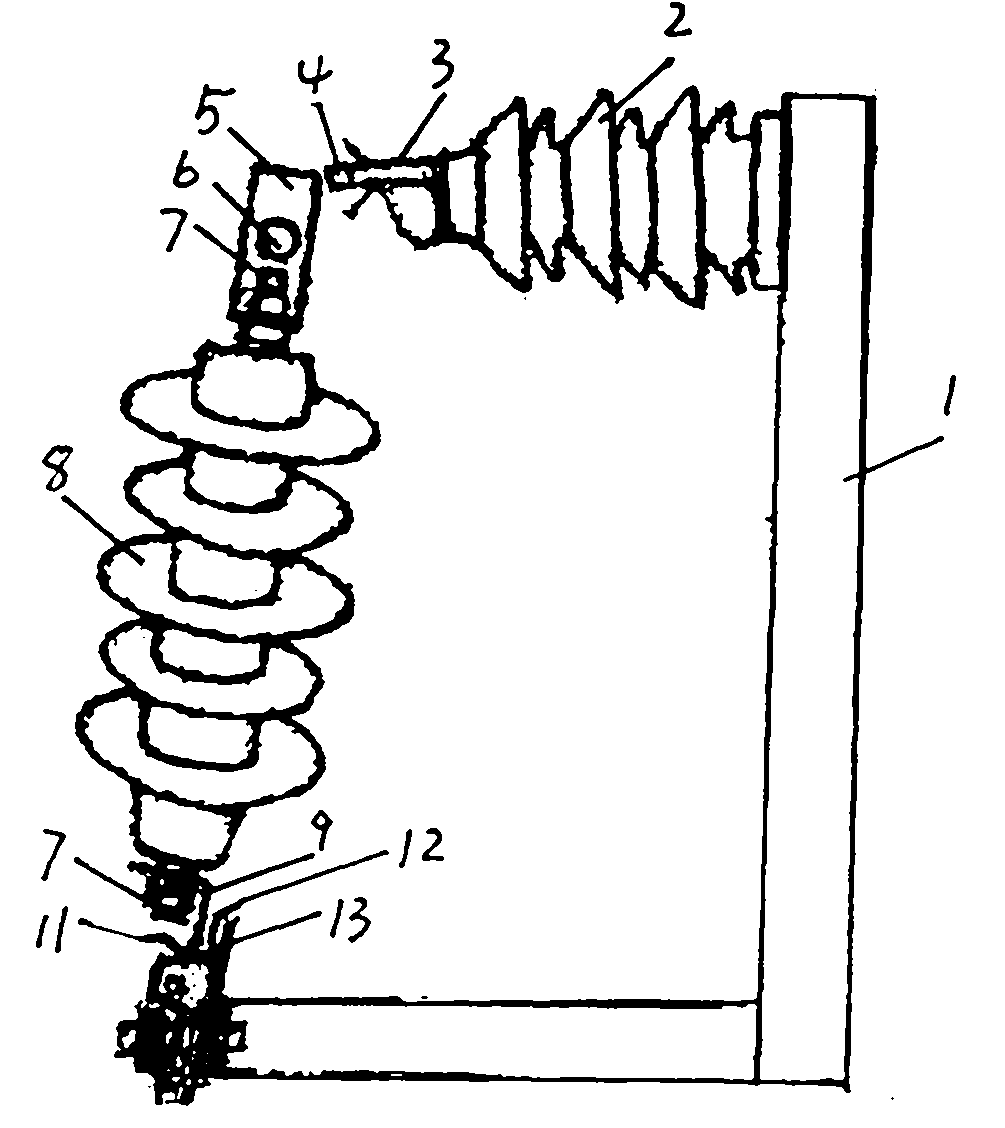

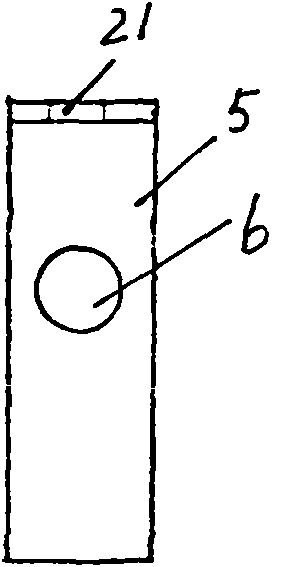

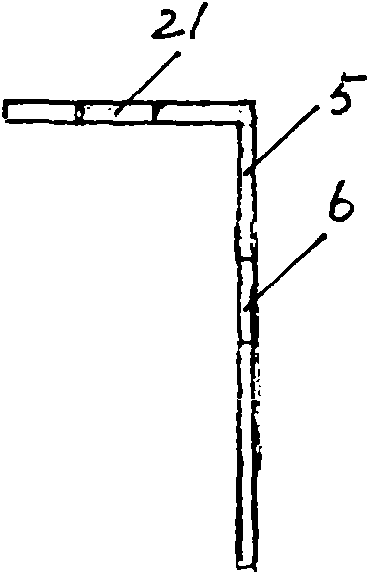

[0025] figure 1 It is the structural diagram of the lightning arrester mounting seat of the present invention, which is composed of angle iron frame 1, supporting insulator 2, upper end socket 3, locking spring 4, upper end plug copper bar 5, operation hole 6, screw rod 7, lightning arrester 8, lower end plug copper bar 9, Buckle spring plate 11, clip spring plate 12, seat cover 13 form.

[0026] When installing the arrester, insert the insulating operating rod into the plug operation hole 6 at the upper end of the arrester, lift the arrester 8 by hand, insert the lower end of the arrester into the lower plug seat first, block the lower end of the arrester with the buckle spring plate, and then pull down the insulation operation forcefully Rod, the arrester upper end plug is inserted in the upper end socket, and the arrester upper end is clamped by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com