Method and device for molding stator core with helix angle

A technology of stator iron core and helix angle, which is applied in the manufacture of stator/rotor body, etc., can solve the problem that the motor cannot be applied with precision control, and achieve the effect of ensuring repeated positioning accuracy, simple processing and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

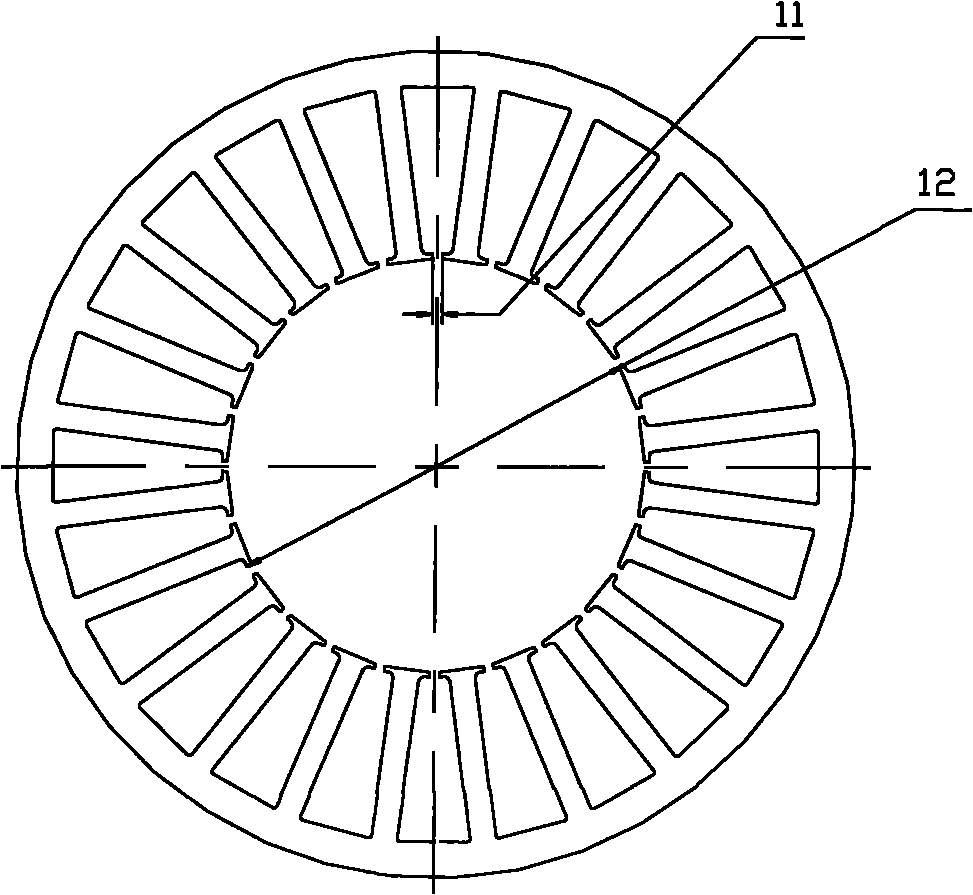

[0038] figure 1 It is the plan view of the stator punching sheet, its inner hole 12 and notch 11 are shown in the figure, the width of the notch 11 is consistent with the width of the spiral rib (51) wound on the surface of the spiral positioning pin (5) cylinder (52), in this implementation In the example, it is 1 mm.

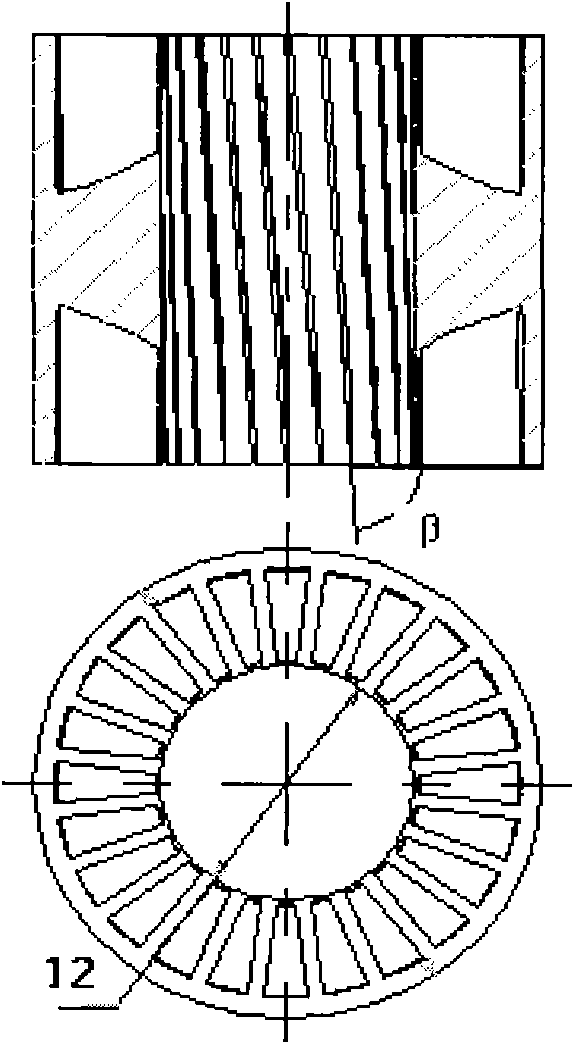

[0039] figure 2 It is a schematic diagram of a stator core with a helix angle. Several stator punches are pressed together according to certain requirements to form a stator core with a helix angle. After forming, all stator punches are concentric, and adjacent stator punches The teeth are staggered by a certain angle β around the center of rotation between the plates.

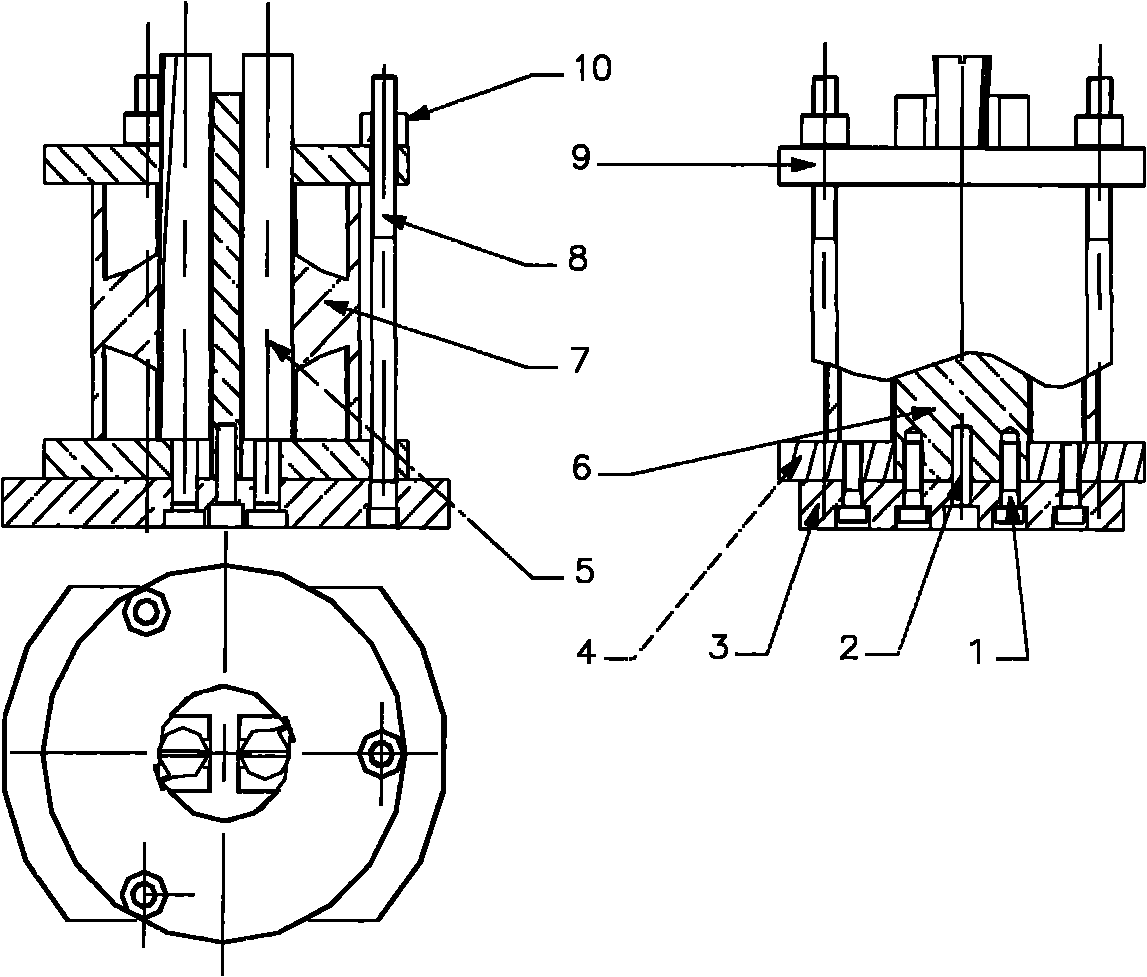

[0040] Such as image 3 , a motor stator core device with a helix angle, consisting of screws (1), cylindrical pins (2), bottom plate (3), backing plate (4), helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com