Dynamic sealing test device and sealing clearance adjustment method

A test device and dynamic sealing technology, which is applied in the direction of measuring device, mechanical component test, machine/structural component test, etc., can solve the problems of increased test data error, large error, and reduced test operation efficiency, so as to ensure uniqueness High accuracy, high precision, reliable test data support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

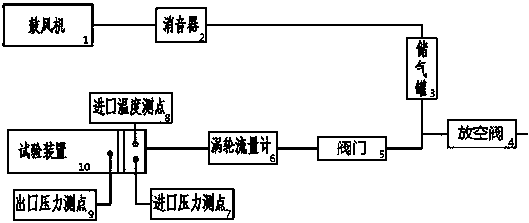

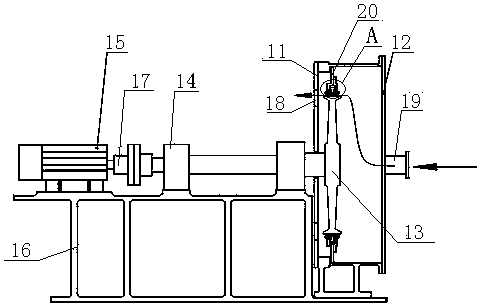

[0026] see figure 1 : This test device is a part of the dynamic seal test system (existing disclosed technology). In the test system, the gas is pressurized by the blower 1 with a large pressure ratio and small flow rate. After the pressurization, it enters the gas storage tank 3 through the silencer 2. The gas is stabilized in the gas storage tank 3. After the pressure is stabilized, it passes through the valve 5 and the turbine. The flow meter 6 enters the sealed cylinder of the test device 10, and the inlet temperature measuring point 8 and the inlet pressure measuring point 7 are respectively set at the gas inlet of the sealed cylinder, and the gas passes through the sealing gap formed by the seal in the test device and the rotor and The gas outlet on the sealed cylinder is discharged into the atmosphere, the outlet pressure measuring point 9 is set at the gas outlet of the sealed cylinder, the vent valve 4 is installed on the pipeline between the valve 5 and the gas stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com