Sealant or filler for electrical and electronic components, and electrical and electronic components

一种电子部件、密封剂的技术,应用在电气元件、电固体器件、半导体/固态器件零部件等方向,能够解决固化不完全、有损密封或填充部件可靠性、固化体硬度不足等问题,达到改善可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

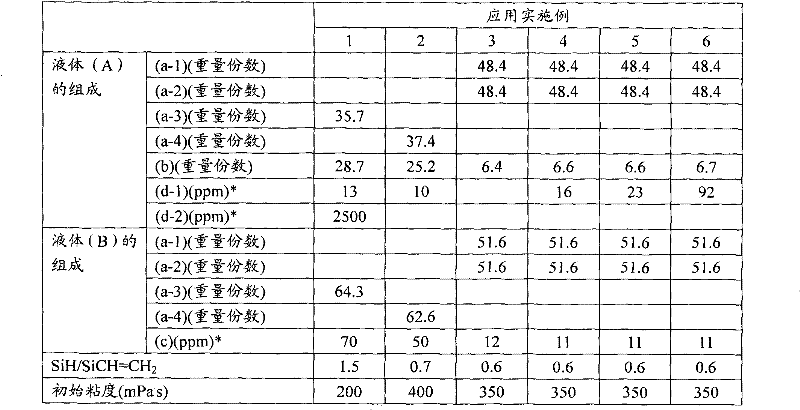

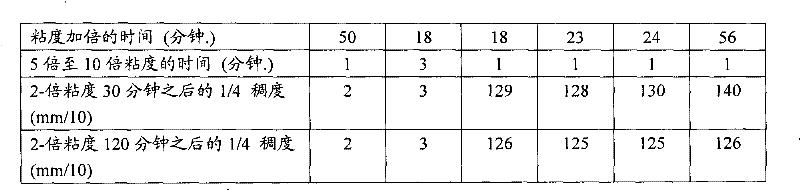

[0035] The inventive sealant or filler for electrical and electronic components and components themselves will now be further described in more detail with reference to application and comparative examples. In these examples, the individual properties have values measured at 25°C. In addition, the properties of this sealant or filler for electric and electronic parts and its cured body were measured by the methods described below.

[0036] [viscosity]

[0037] A two-liquid type organopolysiloxane composition curable by a hydrosilylation reaction was prepared from Liquid A and Liquid B shown in Table 1. The viscosity of the composition was measured directly after the liquids A and B were mixed using a rotational viscometer (Digital Viscometer DVH-B-411, Tokimec Co., Ltd.). This viscosity was taken as the initial viscosity. After that, the viscosity was measured at 25°C for a predetermined period of time. More specifically, the times were measured when the viscosity increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com